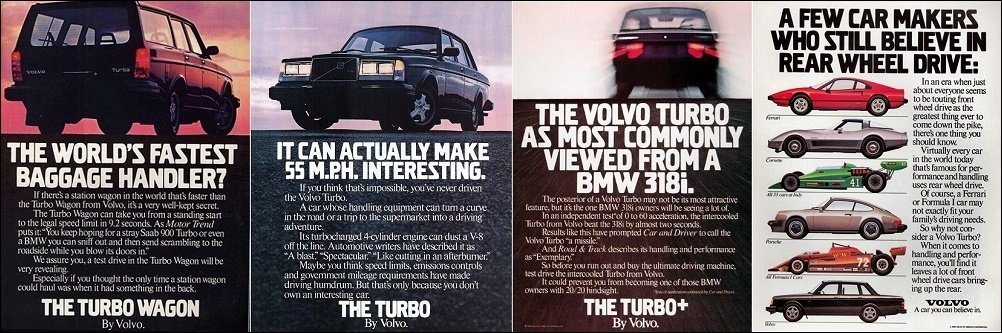

Volvo, once the leading European brand in the Malaysian market, saw its position change after the 1980s. While the products always delivered on the promise of safety, quality and reliability, a pricing strategy that raised prices didn’t work out well and it took a decade to recover. At the time, a senior Volvo executive acknowledged that the idea that it costs Volvo as much to make a car as Mercedes-Benz or BMW meant it could charge almost the same was not necessarily the case.

Nevertheless, the brand slowly rebuilt itself and with a progressive line of products replacing dated models, it has found a niche on which it can grow. Like all companies, Volvo Car Malaysia (VCM) was hit by the effects of the pandemic on the economy and recorded a 56.1% decrease in sales compared to the previous year.

However, things rapidly changed in the second half of 2020 as the numbers surged, thanks to the incentive offered by the government in the form of exemption of sales tax. With Volvo models being assembled locally in Selangor, the exemption was 100%, meaning that customers saved on the 10% sales tax normally imposed.

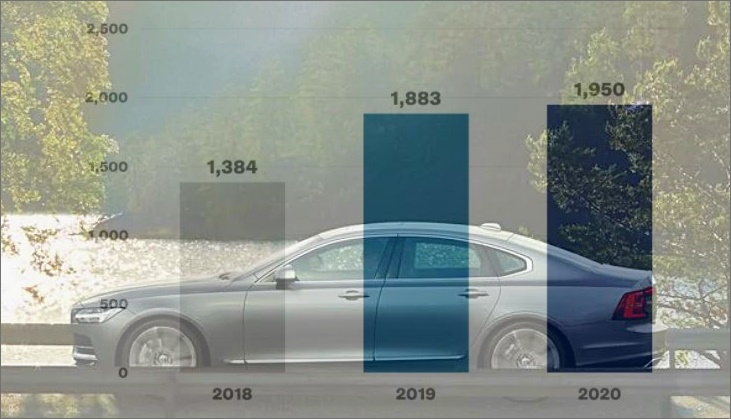

Highest volume since 1999

This allowed pricing to be attractive and along with other companies, VCM saw a boost in sales to finish the year with 1,950 units delivered nationwide. This was a 3.6% increase in volume, surpassing the previous year’s sales figure of 1,883 units and it was also the highest number since the establishment of VCM in 1999.

“We are very proud of what Volvo Car Malaysia has achieved despite this turbulent time and challenges that we faced. Through the collective efforts of our dealers and staff, as well as the opportune timing of the government’s sales tax holiday, we were able to finish a challenging year strongly. For us, seeing the results of our efforts has further recharged our drive to bring more premium, safe and sustainable cars to Malaysians,” said Nalin Jain, MD of Volvo Car Malaysia.

High demand for luxury cars

During 2020, VCM recorded its second-highest sales of the year in July, after the tax exemption incentive under the PENJANA program began (it will continue until the end of June 2021). Mr. Nalin said this was an indication that the demand for luxury cars remains high as the car market began to normalise and the country headed towards recovery.

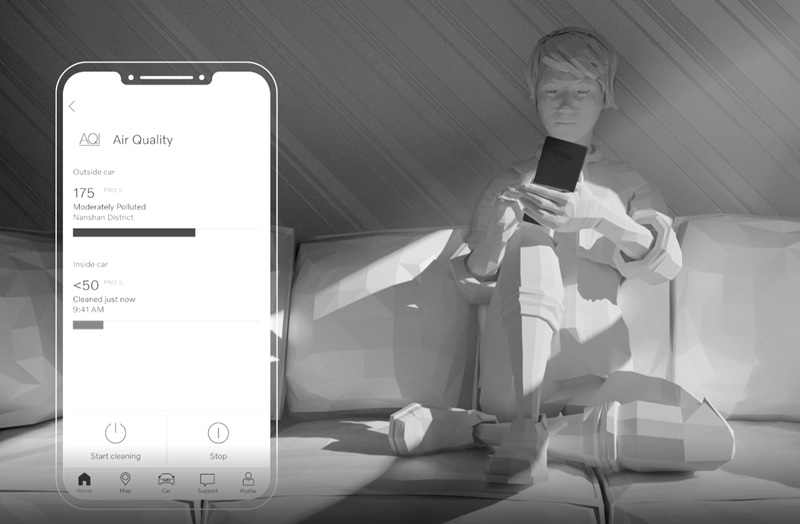

With the renewed interest, VCM reinforced its customer service channels and adopted new digital practices. It introduced a new Online Ordering System for customers to make bookings from their homes or offices, and implemented the Digital Silent Salesman 2.0. This is a platform that digitally displays all necessary details about the cars available in Malaysia.

The new digital practices are part of the company’s push for digital transformation across the entire value chain of its business and reflect its commitment towards its sustainability goals by eliminating printed brochures.

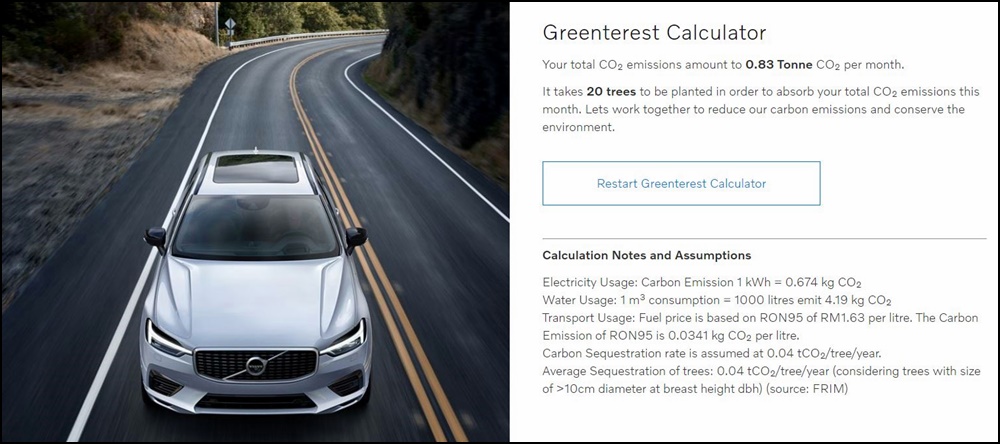

Greenterest Calculator

With sustainability as the forefront of its goals in the coming years, VCM kicked off the ‘Volvo Green Planet’ in the third quarter of 2020. This campaign is aimed at driving awareness about the impact of high carbon footprint, which can be calculated via a Greenterest Calculator. It will bring the conversation to its customers with fully-electric test drives of their cars in a program known as ‘Green Drive’ and dispensing Green Seeds as a token to champion cleaner air.

Recharged 2021 ahead

Based on the past year’s performance, VCM aims to ride on the momentum from 2020, entering 2021 with renewed purpose and recharging all areas of its business. “2021 will be a big year for Volvo Car Malaysia as we look to switch all aspects of our business to incorporate more sustainable solutions and also bring in more products offerings to suit the different needs of Malaysians while helping them make more sustainable choices,” said Mr. Nalin.

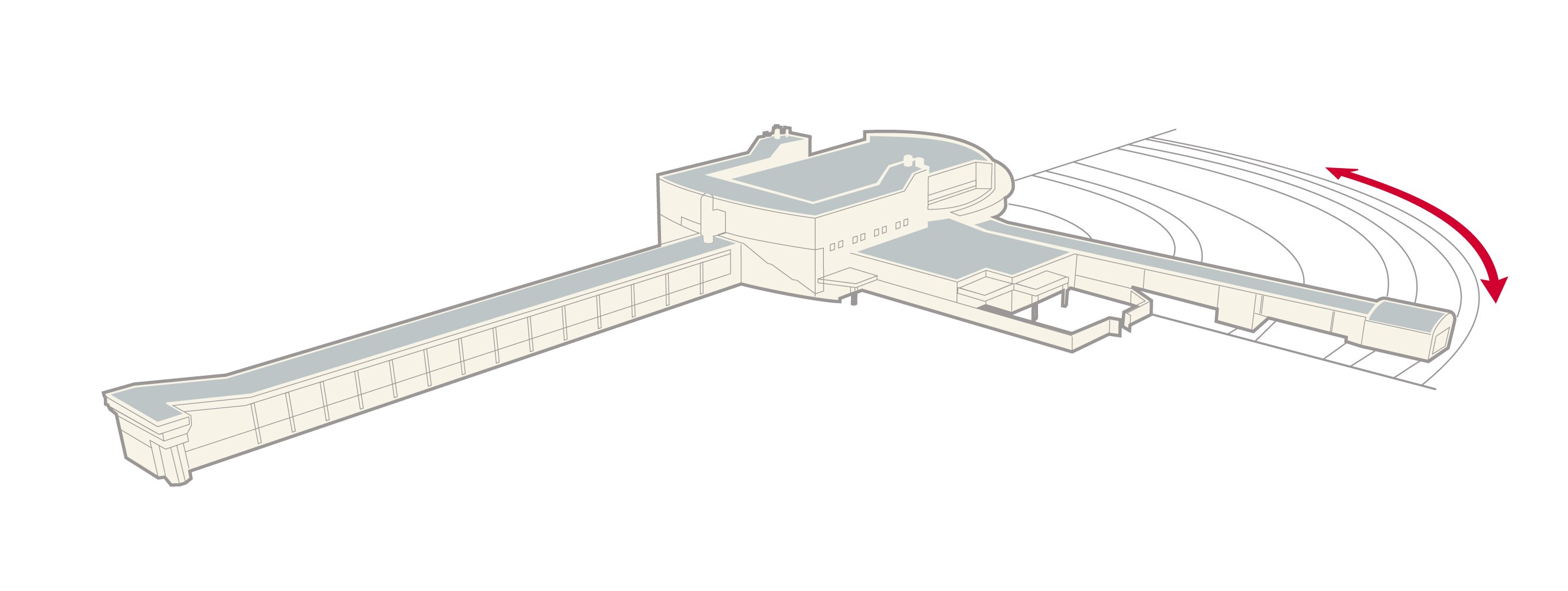

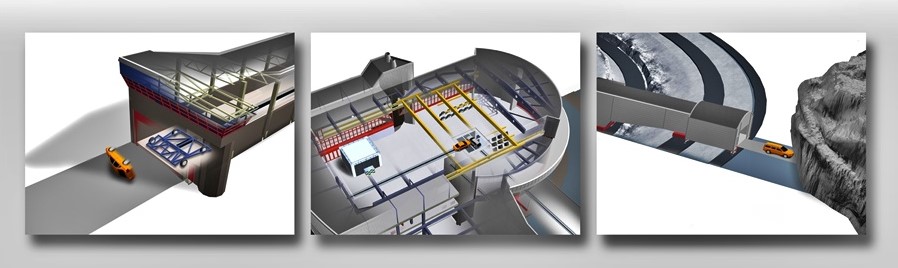

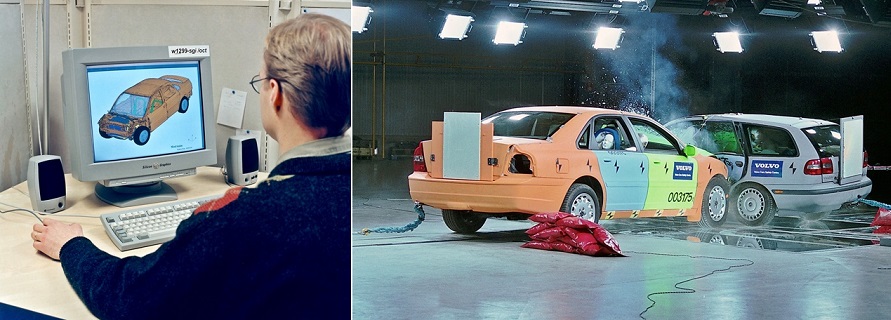

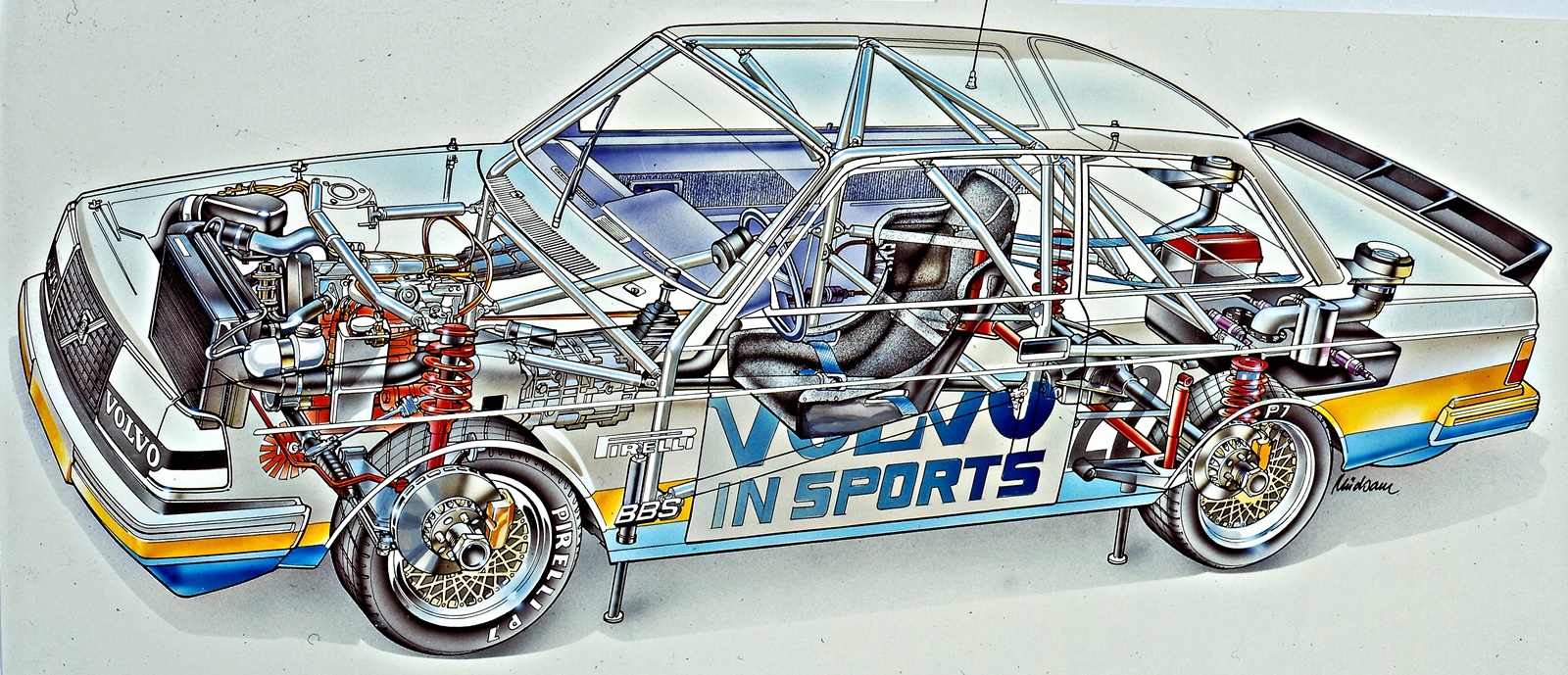

When Volvo drove a car off a building for a crash test (w/VIDEO)