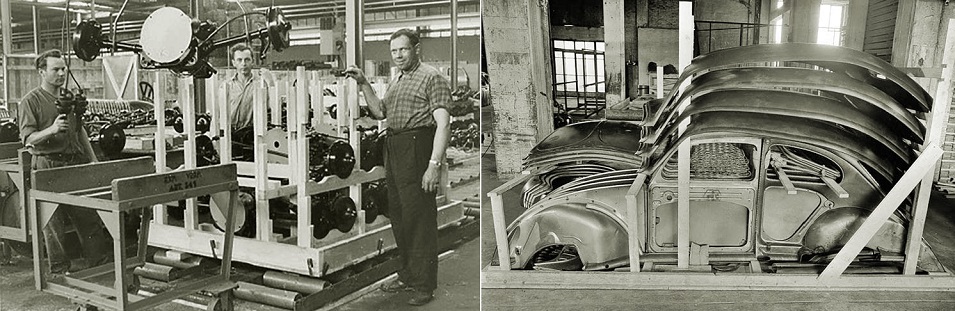

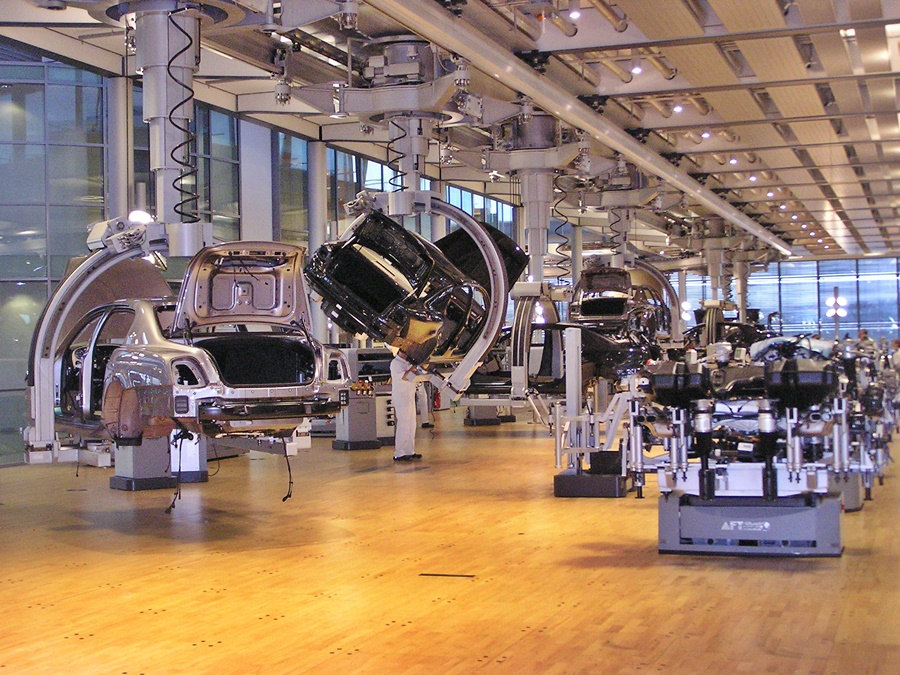

Volkswagen’s Transparent Factory, located in Dresden (which used to be in the former East Germany), began operations in 2002 making the company’s Phaeton luxury sedan. At one point, it was also used for production of the Continental Flying Spur by Bentley, which is part of the Volkswagen Group. The unique factory, with glass walls, also assembled the e-Golf.

Now, it is making the ID, Volkswagen’s range of all-electric vehicles. It is the second production site for the ID.3 and already the fourth site in the world producing Volkswagen models based on the Modular Electric Drive Toolkit (MEB). Over the coming years, the former ‘Centre of Future Mobility’ will steadily transform into the ‘Home of the ID’.

Showcase for mobility of tomorrow

“The Transparent Factory plays an important role within the Volkswagen brand. Here, visitors, customers and guests come into direct contact with the mobility of tomorrow. We are a production plant, tourist attraction, event location, test lab and delivery centre – all in one. With the start of the production of the ID.3, we are giving the green light for our strategic realignment,” said Danny Auerswald, Site Manager of the Transparent Factory.

An additional focus of the strategic realignment is the development of a research and innovation site that drives innovative projects on a pilot scale for later use in large capacity sites at Volkswagen.

Holistic experience

As it was before, the Transparent Factory offers customers, visitors and guests a holistic experience of the ID. family – from initial advice and test drives, to production visits, co-constructing the ID.3 and modern event formats, up to the handover of the electric vehicles.

The first ID.3 rolled off the assembly line recently, and as with the start-up of the e-Golf in 2017, the production of the ID.3 will also start with one shift and 35 vehicles from Monday to Friday. Visitors can tour the factory from Mondays to Sundays.

In future, significantly more vehicles will be handed over to customers in the Transparent Factory. To that end, a second delivery point was recently set up in the factory – which is unique in the automobile industry. The number of vehicle handovers to customers is expected to increase from 1,301 in 2019 and 3,296 in 2020, to more than 5,000 vehicles in 2021. The goal is around 9,700 deliveries a year by 2022.

Conversion of the factory

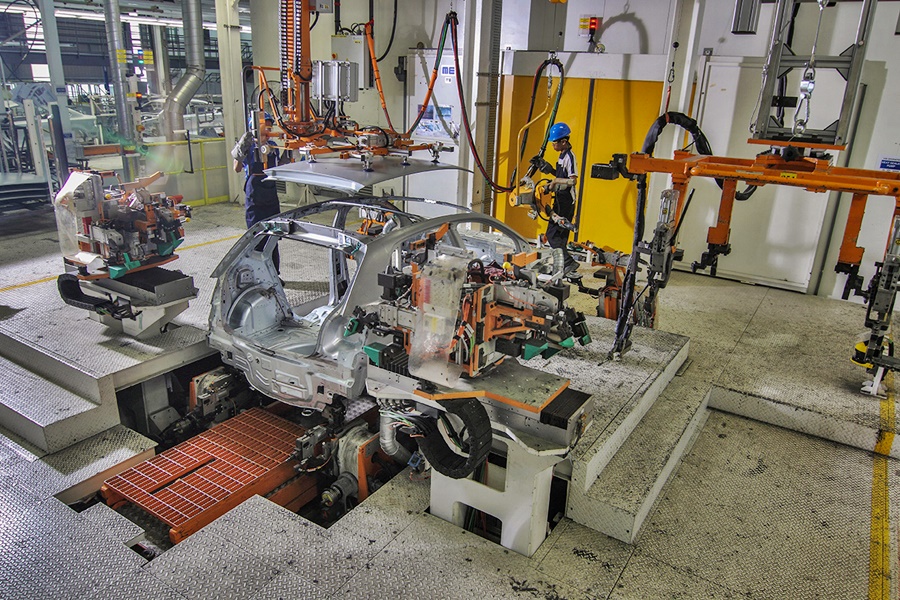

At the beginning of 2021, the production area of the Transparent Factory was converted to meet the requirements of the MEB. The first conversions for the ID.3 already took place in summer 2020. As one of seven stations, the ‘marriage’, where the body and chassis are bolted together, was adapted. The conversion measures include, for example, the installation of a system on which the panoramic roof is fitted and for the adaptation of the gripping devices for installing the cockpit and seat system.

Fourth MEB factory

The Transparent Factory is already the fourth site in the world producing Volkswagen electric cars based on the Modular Electric Drive Toolkit. At the end of 2020, the Chinese sites in Anting and Foshan also started production of MEB vehicles. Together, the two plants in Germany and two plants in China have a maximum production capacity of more than 900,000 vehicles a year. Two more sites in Germany and one in the USA are also preparing for MEB production.

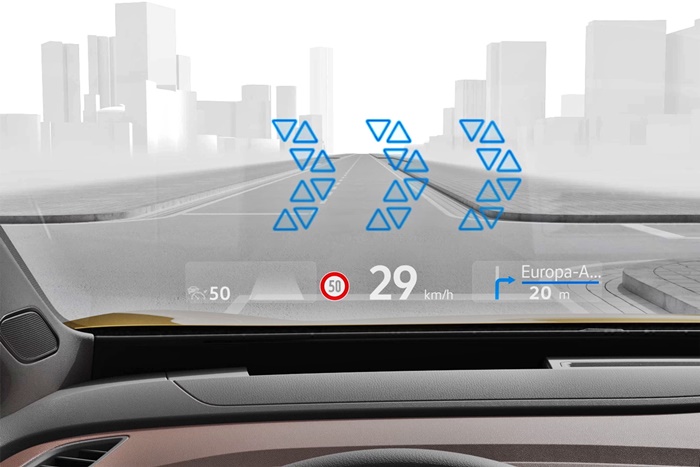

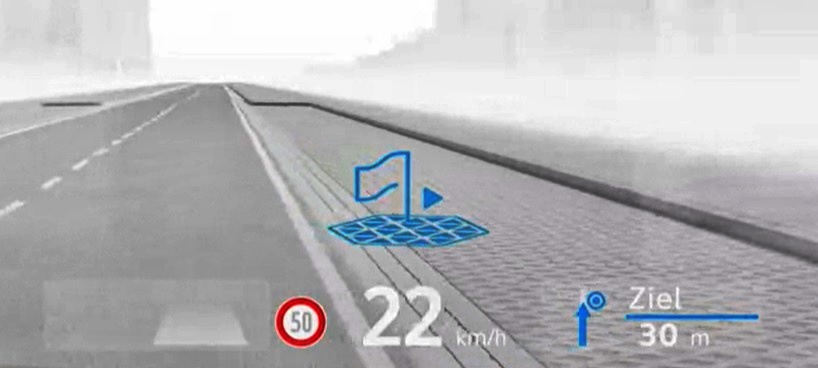

The topic of Production 4.0 will also be driven forward in the Transparent Factory. The guiding principle is the automation and digitalization of complex operations within assembly and logistics. Specifically, the factory will act as a planned pilot plant in the company for the development and application of new technologies in volume production processes.

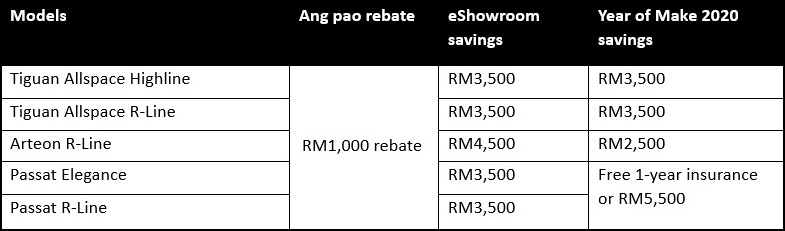

To know about Volkswagen models available in Malaysia, visit www.volkswagen.com.my.