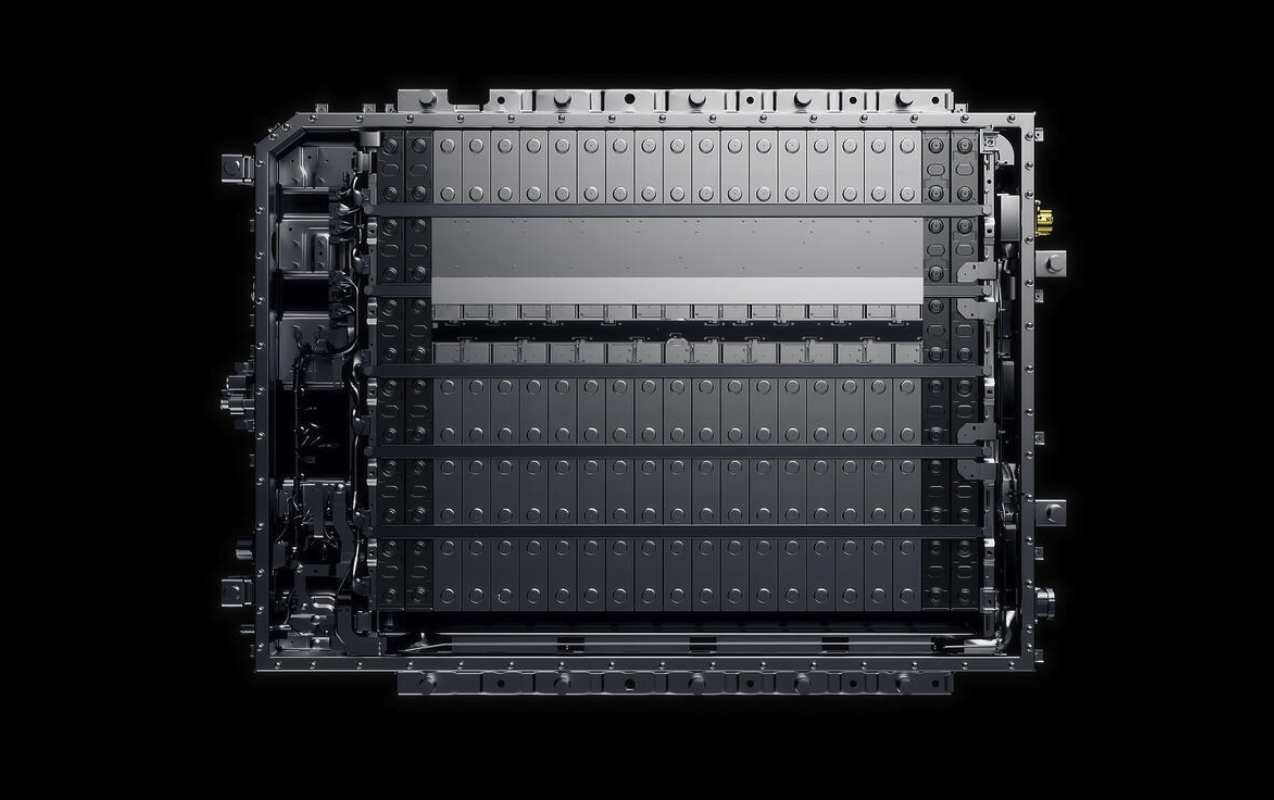

As carmakers make the transition to electrically-powered cars, demand for electric motors is rising. In most cases, the motors come from other companies that have specialised in such powertrains. While this arrangement is cost-effective in some ways. It does not necessarily fully optimise performance in the way the carmaker may want it.

Therefore, in order to have electric motors that are perfectly suited to its own vehicles, Volvo Cars is making significant investments that will allow for in-house design and development of such powertrains. These will be for the next generation of Volvo models as the company continues to move towards becoming a fully electric carmaker.

Addition to global network

The first step is the recent opening company of a brand new electric motor lab in Shanghai, China. This joins the global network of facilities for the development and testing of electric car components. The lab comes in addition to ongoing e-motor development in Sweden and state-of-the-art battery labs in China and Sweden.

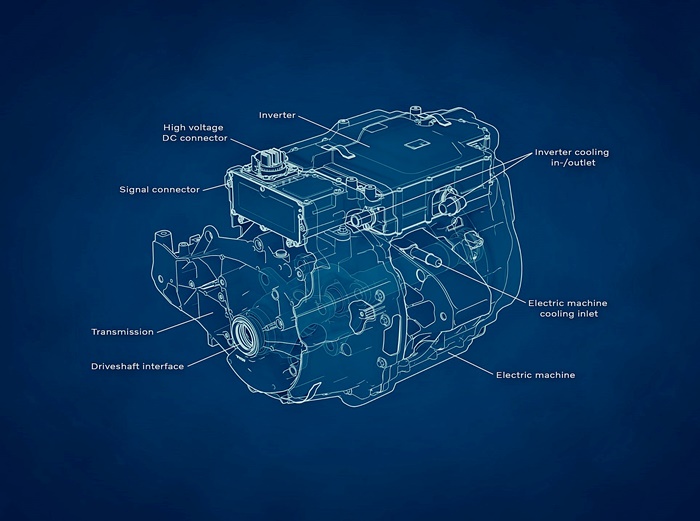

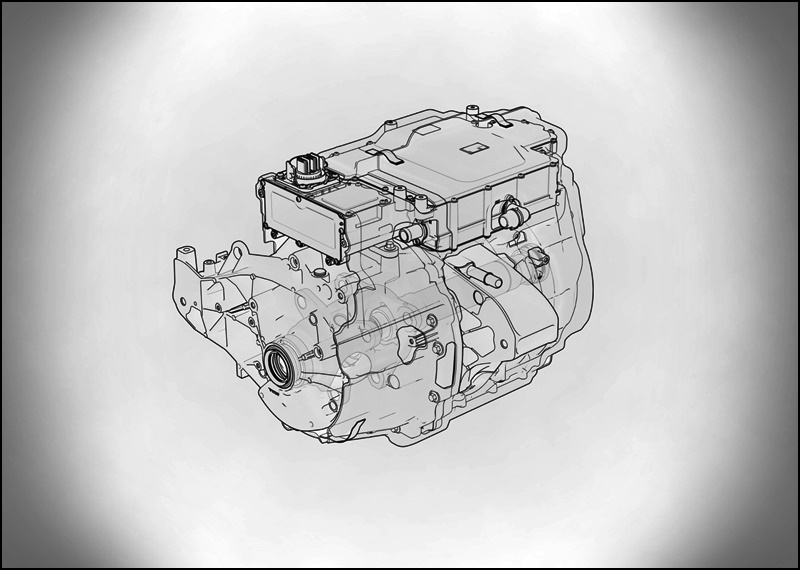

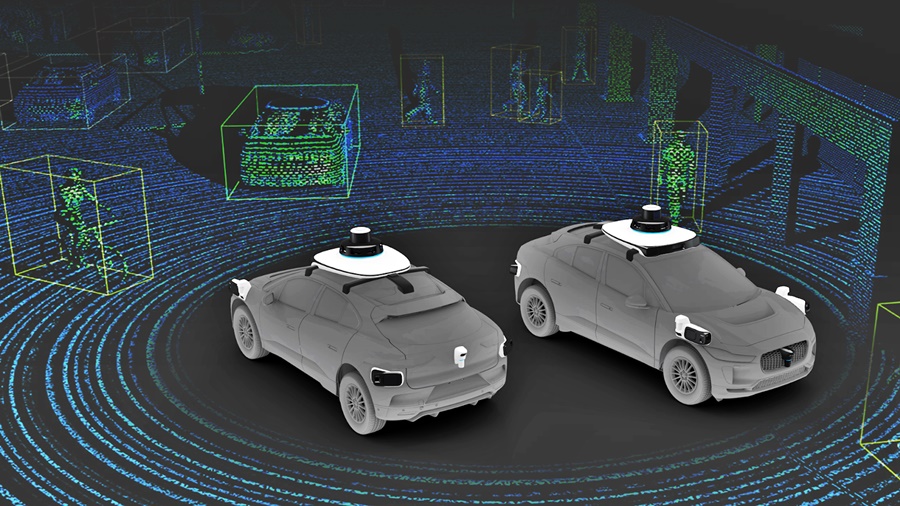

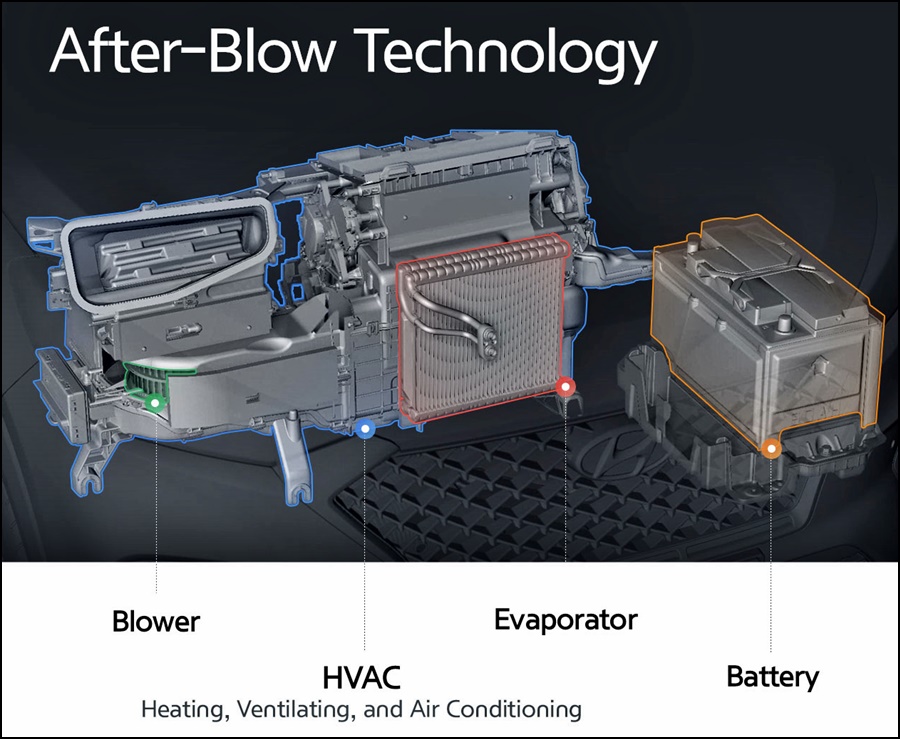

Taking over the role of the internal combustion engine in car engineering, e-motors are a fundamental building block of electric cars, together with the battery and power electronics. The interplay between these three component areas is crucial in developing premium electric cars.

Bringing the development of electric motors in-house will allow Volvo Cars engineers to further optimise electric motors and the entire electric driveline in new Volvos. This approach will allow engineers to make further gains in terms of energy efficiency and overall performance.

Fine-tuning e-motors

“Through in-house design and development, we can fine-tune our e-motors to ever better levels,” said Henrik Green, Chief Technology Officer at Volvo Cars. “By constantly improving their overall performance levels in terms of energy efficiency and comfort, we create an electric driving experience that is unique to Volvo.”

E-motors enable features that electric cars are known for, such as instant acceleration and so-called One Pedal Driving, whereby drivers use the accelerator pedal both for acceleration and deceleration, depending on whether they push in or lift their foot off the pedal.

The newly opened electric motor lab in Shanghai became operational last month. It will mainly focus on electric motor development for use in fully electric and hybrid cars based on Volvo Cars’ forthcoming SPA 2 modular vehicle architecture.

The investments in e-motor design and development represent yet another step towards Volvo Cars’ climate ambitions and electrification strategy. It aims for 50% of its sales to be fully electric vehicles by 2025, with the rest hybrids.

Volvo takes a different approach to helping reduce distractions to drivers