In future, the Porsche you drive could have an invisible ‘twin’ in the digital world. No, it’s not something to do with science fiction and parallel worlds but a possibility being explored by researchers at the German sportscar company. With continuously improving performance of integrated sensors, networking and data processing capabilities, it may become possible to create a virtual copy of an existing object – like a car. This will allow data-driven analysis, monitoring and diagnostics without the challenges and constraints of real-world tests.

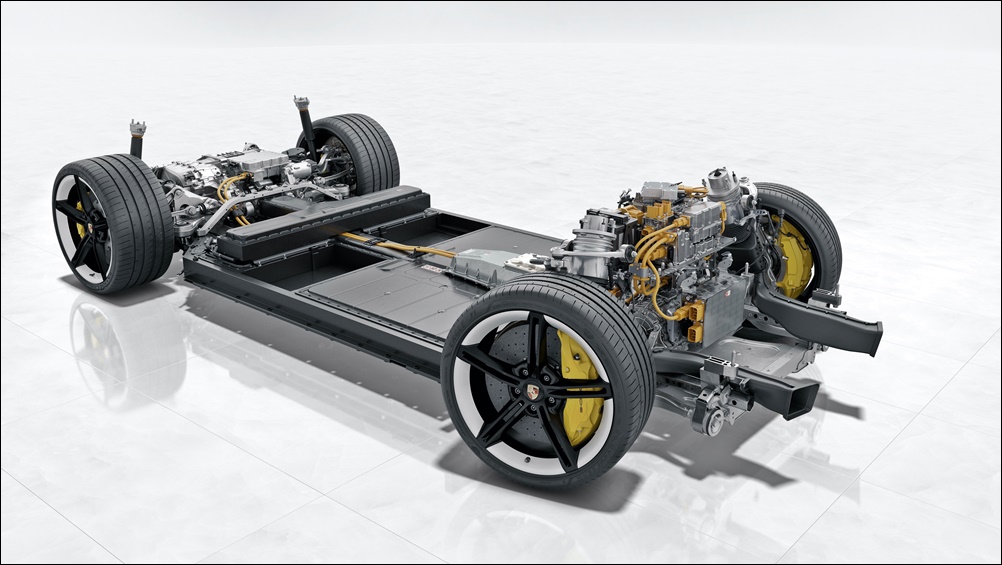

The digital twin of a vehicle comprises not only the operating data it collects but also any related data, such as information collected during planned maintenance work and unexpected repairs. Elements of this digital twin already exist in control unit memories and in the databases maintained at Porsche Centres.

Centralised intelligence system

The main advantage of digital twins is the fact that they can be networked and the data combined with a centralised intelligence system. Conclusions that benefit every single vehicle and therefore every individual customer can be drawn from data relevant to an entire field. For example, an algorithm can compare big data against sensor data from a specific vehicle’s powertrain and chassis to identify a customer’s driving style.

The algorithm can then recommend not only the optimal time for service work on the vehicle but also the required scope of that work. This data makes it possible to customise service intervals and allow servicing for specific components as needed, based on how the customer uses their vehicle.

For instance, with this approach, the hardworking suspension bushes of a sportscar that spends most of its time on a racetrack could be replaced at exactly the right time. By contrast, service work on the engine is more important for vehicles predominantly driven for long distances on motorways. Another even more important benefit of this approach is the fact that potential component wear and even faults can be identified before they have actually occurred, which is a significant advantage from a safety perspective.

For the past 3 years or so, software specialists at Porsche have been working on a digital twin concept that focuses on the chassis, known as a ‘chassis twin’. This project is now being managed by CARIAD, the standalone automotive software company within the Volkswagen Group. In addition to data from Porsche vehicles, the project now has access to data from all Volkswagen Group vehicles, which increases the data pool by a factor of 20.

High importance of the chassis

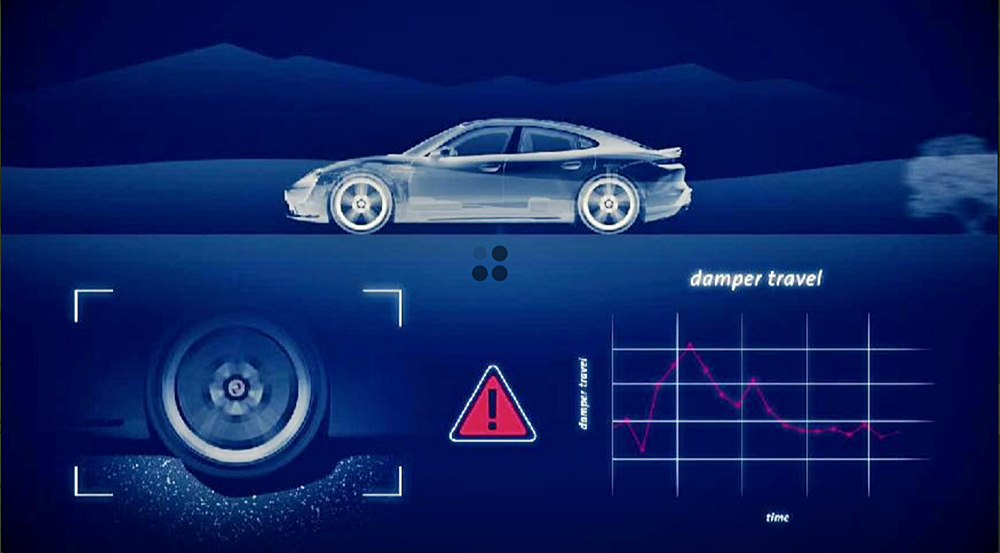

The reason for focusing on chassis components is clear. On a Porsche, the chassis is subjected to the highest loads, particularly when the vehicle is used on racing circuits. Sensor technology in the vehicle and the intelligent neural algorithms used for centralised analysis allow the load on the chassis to be detected within the vehicle and conveyed to the driver. This intelligent use of data makes the vehicle safer for its passengers because any specific faults are identified immediately, even before the driver or the workshop notices a problem signified by noise or vibration.

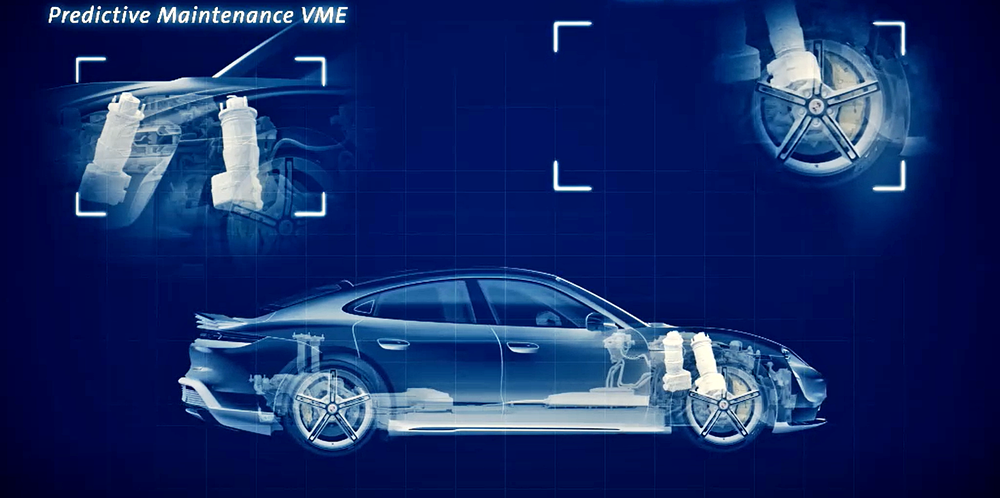

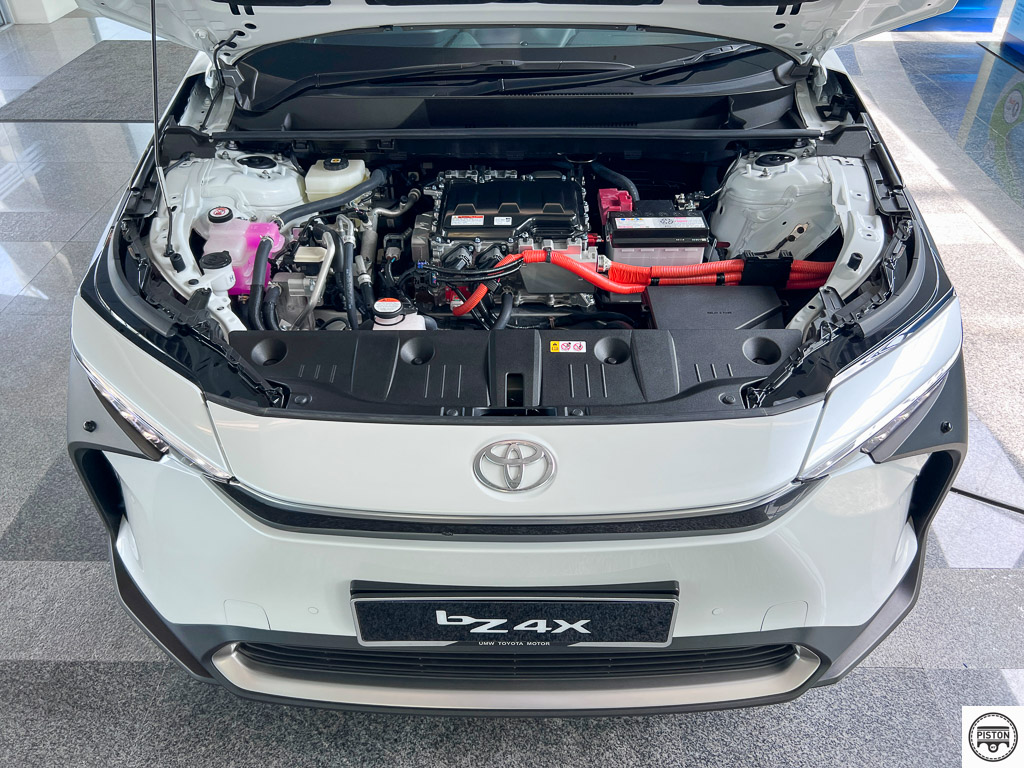

The digital chassis is already being used for its first practical testing scenario: monitoring the components in the air suspension of the Taycan EV. This project is primarily for collecting data about body acceleration in this initial stage. The data is evaluated and transferred via Porsche Connect to the central backend system.

This system continuously compares the data from each vehicle against the fleet data. The algorithm calculates thresholds based on this comparison and, if these are exceeded, the customer is notified via the onboard Porsche Communication Management (PCM) system that the chassis may need to be inspected at a Porsche Centre. While this approach ensures that wear does not go beyond specified limits, early repairs also help to prevent consequential damage.

Artificial intelligence with data privacy

Artificial intelligence within the vehicle and within the centralised intelligence system continuously improves contingency planning and the accuracy of the algorithms. Data privacy during the testing phase and after the model’s launch is the top priority so customers are prompted via the PCM to provide their consent to data being collected anonymously. Around half of all Taycan customers have agreed to take part in this pilot project, which has pleased Porsche.

The first version of the digital twin will be launched next year and only sensor data directly from mechatronic components will be evaluated. Other functionality will be added in the future, such as functions that allow wear on specific components to be calculated without the need for physical gauges to be used. For example, if multiple vehicles require adjustments to their wheel alignment or a track rod replacement and multiple sensors have already detected corresponding deviations, this information can indicate a pattern. If the same data is then identified on a further vehicle, the driver will accordingly be told to visit a Porsche Centre.

Early diagnostics in this format can prevent consequential damage which, in this example, would be worn tyres caused by track misalignment. The fault-finding process at the workshop will be faster, because the specific components responsible for a fault can be replaced, thereby reducing throughput times in the workshop and lowering costs for customers.

The digital twin offers other benefits for customers beyond operation of their vehicle. Digital vehicle records can be used to show the residual value of a vehicle, making the process of buying and selling used vehicles more transparent. In addition, manufacturers could consider offering an extended approved warranty based on seamless documentation of component status updates, and even a certificate with a price recommendation for selling on the vehicle.