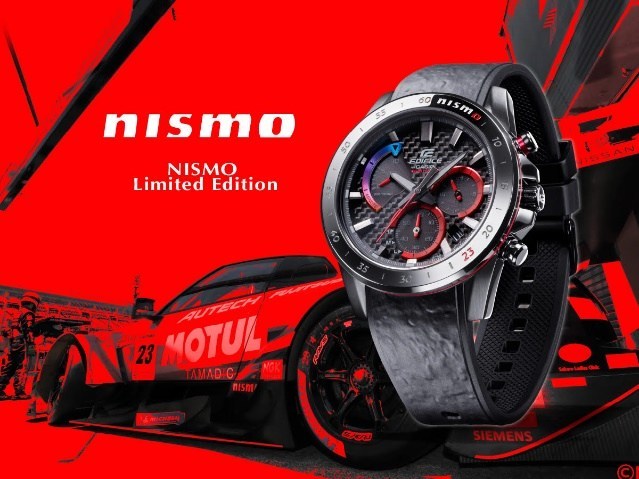

It wasn’t surprising when Nissan was the first Japanese carmaker to become involved in Formula E which is now a world championship. The carmaker became dominant in the electric vehicle (EV) segment after introducing the world’s first mass-produced EV, the LEAF in 2010, so it was natural for it to participate in the all-electric series.

That was back in 2018 when the company partnered the e.dams team and started off in the fifth season of the series. It drew on its experience developing EVs to develop a new powertrain package for its Formula E car, including a new electric motor, inverter, gearbox and software.

Following its entry in the fifth season, the team has been among the regulars each season and in March 2021, Nissan confirmed further commitment to Formula E. Now, the company is going on step further by acquiring the French-based e.dams team which will finish off this season with the Gen2 car and then start the next season with the new Gen3 racing car. Nissan will be present until the end of Season 12 (2025/26).

“It’s taken years of planning and months of intense preparation, but we’re now ready to hit the track for our Formula E race debut,” said Michael Carcamo, Nissan’s Global Motorsports Director. “We’ve drawn on our experience as a global leader in electric vehicles for the road to help develop our Formula E powertrain – and what we now learn on the track will go back the other way, benefiting Nissan’s electric-car customers.”

Nissan’s participation in Formula E supports the company’s long-term commitment to electrification and sustainability laid out in Nissan’s ‘Ambition 2030’ plan. “These are exciting times for all of us at Nissan, our fans and customers everywhere,” said Ashwani Gupta, Nissan’s Chief Operating Officer. “We have been on the grid for over 85 years, and our desire to win continuously accelerates us forward. We learn as we race, and the relentless pace of technological progression that drives the Formula E championship will provide us with many opportunities to inform and develop even better cars for customers.

As part of its goal to achieve carbon neutrality across its operations and the life cycle of its products by 2050, Nissan intends to electrify all its new vehicles by the early 2030s in key markets. The Japanese carmaker aims to bring its expertise in transferring knowledge and technology between the Formula E racetrack and road for better electric vehicles for customers.

“I am delighted that Nissan is taking over e.dams and today we are thinking of Jean-Paul Driot who, together with Nissan, had the vision for the team and helped to develop our partnership,” said Tommaso Volpe, who will become the Managing Director of the Nissan Formula E team. “Since his passing in 2019, Olivier and Gregory Driot took over and made sure the legacy of their father’s success would continue. It has been a pleasure working together and I would like to thank them for their commitment and support.

“We are very proud to hand over the e.dams team to such a committed and innovative company as Nissan. We’ve had several open discussions in recent months with Nissan and we decided that it was the right time for them to take the reins and continue the legacy of our family and secure the long-term future of the employees,” said the Driot brothers.

Nissan e.dams team ready for first round of Formula E Season 8 in Saudi Arabia