To locate a showroom to view, test-drive or purchase a model, visit www.honda.com.my.

To locate a showroom to view, test-drive or purchase a model, visit www.honda.com.my.

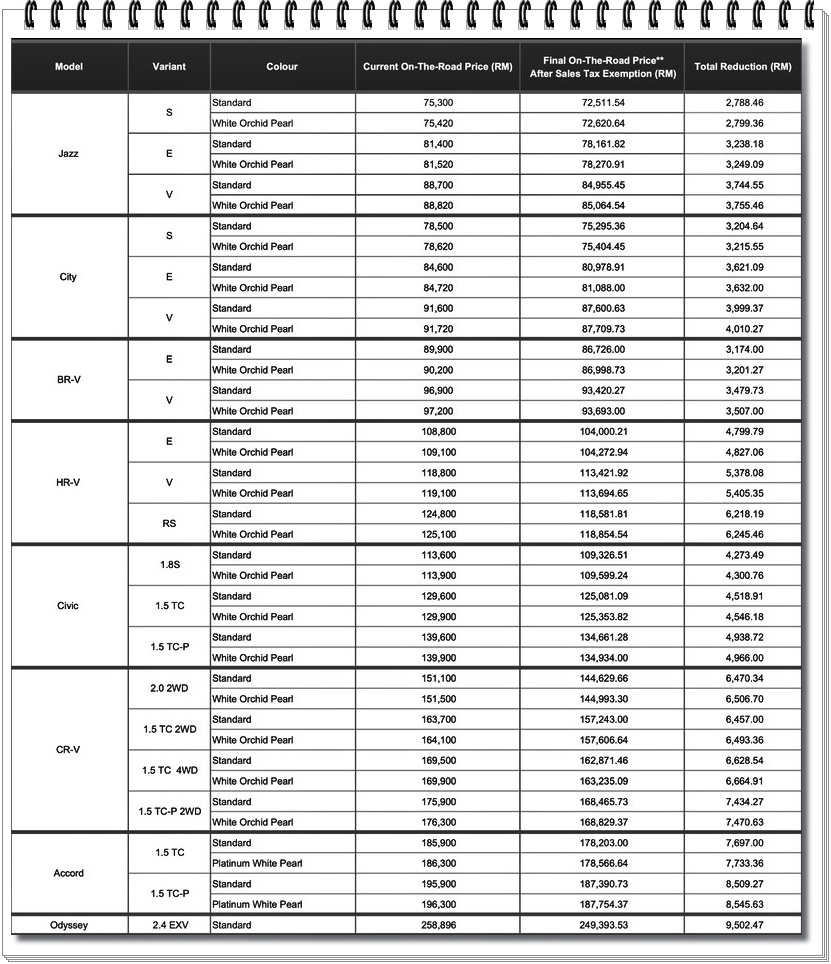

Seems like with the industry resuming business, the car companies are trying to quickly make up for the lost months and deferred product introductions. After recently starting deliveries of the updated Honda BR-V, Honda Malaysia has now also announced an update for the RS version of the popular HR-V crossover SUV.

Second choice for interior colour

The update is a new interior colour – a classy dark brown leather which customers can choose as an alternative to the existing black leather theme. The dark brown leather materials are fitted to the centre console, front panel, driver and passenger seats (front and rear) as well as door panel lining.

No change in price

The price remains as RM124,800 (without insurance). Colour options are Passion Red Pearl, Modern Steel Metallic and White Orchid Pearl.

Launched in 2015, there are more than 91,000 units of the HR-V on Malaysian roads. Right from the start, it was a hit as it arrived at the right time when the SUV market boom was accelerating. The facelifted HR-V which was introduced in January 2019 has sold more than 19,000 units with the RS variant contributing 21% to the total.

The HR-V RS is powered by a 1.8-litre SOHC i-VTEC engine and uses an Earth Dreams Technology Continuous Variable Transmission (CVT). Functional features include a 7-inch display screen for the infotainment system, paddle shifters and the very useful LaneWatch system which provides a real-time view of the blindspot on the left side of the vehicle.

“The HR-V RS received overwhelming response from the market since we introduced it in early 2019. Then, based on customers’ feedback for an enhanced touch of sophistication, we introduced the stylish black leather interior for the HR-V RS. We are delighted to provide yet another selection of interior styling to suit the differing personalities of our discerning customers – the new classy dark brown leather interior. We are committed to continuously improve our product offerings as we listen to customers’ feedback and market demand,” said Honda Malaysia’s Managing Director & CEO, Toichi Ishiyama.

Safe practices implemented at all authorised Honda dealerships for customers’ peace of mind

Carmakers may spend a lot of money on racing activities but in many cases, such activities also support R&D for the company to develop new technologies for future models. Honda has been on such company and even in the 1960s, before it was established as a serious carmaker, it was already in Formula 1, the first Japanese company to do so.

Honda’s founder believed that the experience of working in a racing team was invaluable for the engineers. They had to find solutions to problems very quickly and in the high-pressured environment of motorsports. The benefits were understood, and Honda made sure that it remained active in motorsports, with many technologies flowing to production models.

The latest Jazz is an example of advanced Honda hybrid innovation transferring from the racetrack to the road. Using engineering expertise from its motorsport team, Honda is drawing knowledge from its Formula 1 Hybrid Power Unit (PU) programme to improve the energy efficiency of the brand’s e:HEV hybrid system.

The latest Honda Formula 1 Hybrid Power Unit, named RA620H, uses a highly efficient 1600 cc 6-cylinder internal combustion engine, combined with an Energy Recovery System. The advanced hybrid electrical systems ingeniously recycle energy produced by the brakes and exhaust gases to generate extra boost power for acceleration and to reduce turbo lag.

Last season, Honda’s Hybrid Power Unit helped its partner teams, Aston Martin Red Bull Racing and Scuderia Toro Rosso (now known as Scuderia AlphaTauri), achieve a total of 3 race wins and 6 podium places.

During races, Honda Formula 1 engineers are constantly assessing and changing the ratio of energy recovered and deployed by the hybrid system to deliver optimum performance. The expertise they have developed in running hybrid power units at optimum efficiency and power output inspires Honda’s range of advanced e:HEV powertrains in its passenger cars.

The beneficiary of this technology is the Jazz. Its e:HEV hybrid system recycles energy and harnesses it to charge the battery and support engine output, for strong performance, seamless switching between drive modes and maximum efficiency.

“During a Formula 1 race weekend, teams have to manage very carefully how much fuel they use to comply with the sport’s regulations. In a race, we can divide the total fuel allowance over the number of laps, but there are going to be situations where a team might wish to use more fuel in order to get higher performance and in other parts of the race they will want to save fuel for later, while behind a safety car for example,” explained Yasuaki Asaki, Head of PU Development.

“In a race, the communication between the race engineer and the driver is key to achieving that best balance. However, in our road-going e:HEV hybrids, we apply our expertise to ensure the Powertrain control units deliver the best possible power to efficiency ratio for the driver, in any required driving mode,” he said.

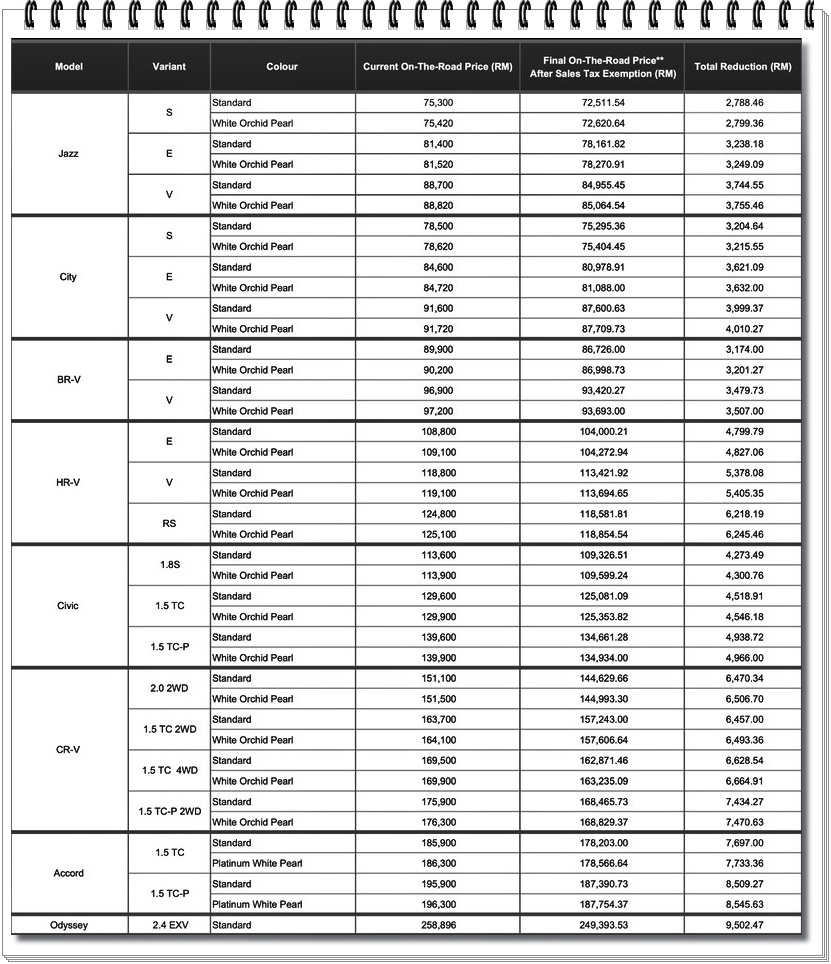

The e:HEV system (shown above) is newly developed for Jazz consists of two compact, powerful electric motors connected to a 1.5-litre DOHC i-VTEC petrol engine; a lithium-ion battery; and an innovative fixed-gear transmission via an intelligent power control unit.

To deliver a rewarding driving experience and exceptional efficiency, the e:HEV hybrid set-up seamlessly selects from three interchangeable drive modes:

EV Drive: the lithium-ion battery supplies power to the electric propulsion motor directly.

Hybrid Drive: the engine supplies power to the electric generator motor, which in turn supplies it to the electric propulsion motor.

Engine Drive: the petrol engine is connected directly to the wheels via a lock-up clutch and drive force is transmitted directly from engine to the wheels.

In most urban driving situations, optimum efficiency is achieved through seamless transitions between EV Drive and Hybrid Drive. At highway speeds, Engine Drive is used, supplemented by an on-demand peak power ‘boost’ from the electric propulsion motor for fast acceleration. In Hybrid Drive, excess power from the petrol engine can also be diverted to recharge the battery via the generator motor. EV Drive is also engaged when the car is decelerating, harvesting energy through regenerative braking to recharge the battery.

Rather than using a conventional transmission, the Jazz is equipped with a newly-developed Electronically Controlled Continuously Variable Transmission (eCVT) with a single fixed-gear ratio to create a direct connection between moving components. This transfers torque with a linear feel during acceleration across all drive modes.

The war against the COVID-19 coronavirus is a global one as 196 out of 197 countries have cases. Besides government efforts, individuals, various types of organisations and companies are also contributing in various ways. Where the auto industry is concerned, R&D capabilities and mass production facilities have been used to make much-needed Personal Protection Equipment.

Some carmakers have also looked at how they can make their vehicles safer for healthcare workers to travel in. Unlike making conventional ambulances which would usually transport patients without infections, the ones used to transport people potentially infected with COVID-19 must be designed to protect the healthcare workers and also the driver and other crew.

In America, Honda has made modifications and installed additional items in 10 units of the Odyssey MPV for use by the City of Detroit. To protect the health of the driver from the potential for droplet infection during transportation, the MPVs have been fitted with a plastic barrier installed behind the front seating area. Modifications have been made to the ventilation system to maintain an air pressure differential between the front and rear seating areas.

The MPVs were configured by a team of volunteers at Honda’s R&D centre in the state of Ohio. Senior engineers and fabrication experts quickly conceived and designed a method to modify the Odyssey at the company’s vehicle development centre where it was originally developed. They took less than two weeks from initial concept to completion.

All material fabrication and installation, and adjustments to the software for the Odyssey’s ventilation system, was done entirely in-house. The software controlling the ventilation system was tuned to assure the air pressure to create an environment inside the cabin like the negative pressure rooms in medical and research facilities.

Specifically, the software has been tuned to run the blower motor powering the fans in the front seating area faster than the fans for the rear seating area. The resulting air pressure differential creates a more negative pressure chamber in the rear seating area, with rear compartment air exhausted out the vents in the rear of the vehicle. This would greatly reduce the potential for droplet infection migration during transportation.

War on COVID-19: Mercedes-Benz converts bus specially for transporting patients

Selected authorized Honda dealerships have begun to resume operations from today (April 29) as permission has been granted by the Ministry of International Trade and Industry (MITI). All service centres in the country had to be closed earlier under the Movement Control Order (MCO) which came into effect on March 18, 2020.

During the period of closure, only emergency services were permitted to assist owners to move their vehicles which may have been immobilized. However, no repair work or maintenance was allowed, and the vehicles had to remain in the service centre for the duration of the MCO.

“Honda Malaysia is truly inspired by the spirit of Malaysians, especially all the frontliners, to overcome the unprecedented situation. The journey to flatten the curve has been tough and extensive but we are ‘Together As One’, staying home in order to have a better outcome for all. We will comply with the extension of the MCO in support of the efforts taken by the Malaysian government and people amid the current situation,” said Honda Malaysia’s Managing Director & CEO, Toichi Ishiyama.

“At the same time, customers need to have their cars in good, reliable condition and hence, require maintenance service. As we resume our aftersales services, we emphasize the importance of continuing to adhere to the MCO rules, being attentive and to take precautions especially in hygiene through frequent sanitization and disinfection, general cleanliness and social distancing,” he added, giving assurance that the precautionary and control measures will be strictly implemented at the Honda dealerships to provide a safe environment during customer visits.

Procedures at service centres

Upon arrival at the dealership, customers will undergo temperature scanning and hand sanitizers have been prepared for their use while their appointment status is being verified. Individuals recording temperature of 37.5 degrees C. and above or are exhibiting symptoms of fever, cough and shortness of breath will be advised to leave the premises to immediately seek medical attention.

Honda Malaysia has also asked its dealers to enforce stringent measures concerning crowd control and social distancing. The number of customers present at any one time for their vehicle service in the dealership shall be limited at minimum capacity. It is compulsory for customers to make appointments with their nearest dealer (within 10 kms of their home) to smoothen their visit and ensure the availability of a slot for their service before going to the service centre.

To facilitate social distancing, the dealers are commencing a car drop service. This new service allows customers with appointments to just drop off their cars at the dealerships and conduct discussion on their car service updates or enquiries via telephone with the service advisors so as to maintain social distance. This practice will not only help safeguard the well-being of the customers and service advisors, but also provide substantial convenience to Honda owners.

Honda Malaysia is also taking extra precautions to ensure the highest safety and good personal hygiene of service advisors. Temperature checking will be implemented on employees and they are reminded to wash their hands regularly, and practice social distancing by maintaining a distance of 1 metre from one another at all times. Hand sanitizing stations are set up for the convenience of service advisors and customers, and some areas in the dealerships will be restricted or remain closed to ensure customers safety.

The lead-acid batteries in motor vehicles have been around for many decades and because they are made from elements that can be recycled, there is an established ‘business’ in collecting and recycling batteries. Even the guy who collects old newspapers will take them as the lead, plastics and even the sulphuric acid can also be recycled.

Lead-acid batteries are therefore considered as ‘closed-loop’ products which means that when their ‘first life’ is over, they can be recycled into other products. It is estimated that globally, 98% of such batteries are being recycled.

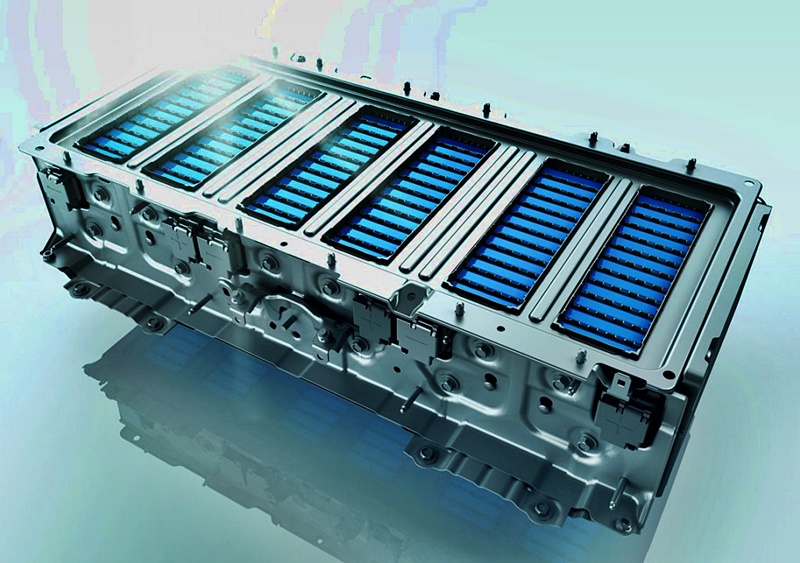

With the advent of hybrid and electric vehicles since the late 1990s, more powerful battery packs have appeared. These are needed to store electricity in large amounts and to power the electric motors. These have not continued with the lead-acid approach which would make the battery packs very heavy as they would have to be very big to store sufficient electricity.

Instead, the battery packs for battery-powered electric and hybrid vehicles use nickel-cadmium (NiCd), nickel–metal hydride (Ni-Mh), and more recently, lithium-ion or lithium-ion polymer. The technology is constantly advancing, and the battery packs are getting more compact while their storage capacity keeps growing, making possible longer travel ranges.

End-of-life disposal

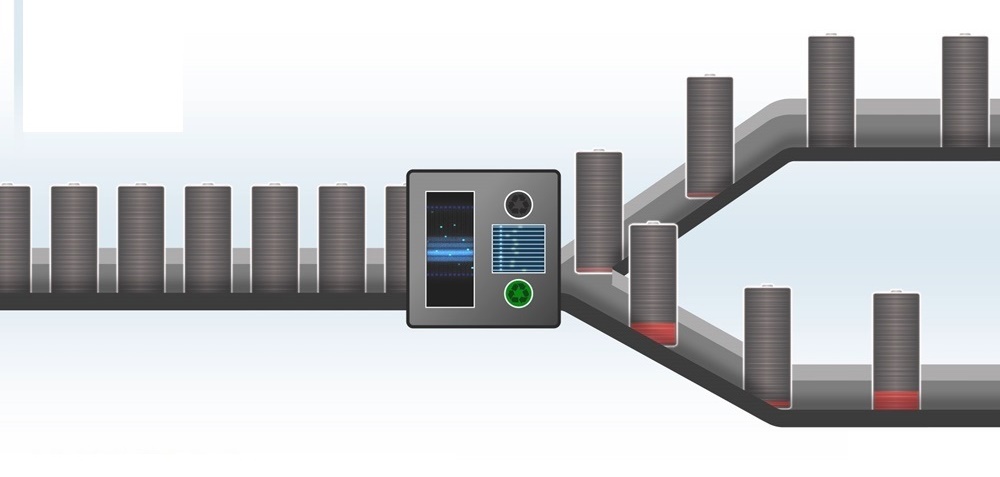

The manufacturers have been mindful of the fact that the battery packs have an end-of-life and unlike lead-acid batteries, their disposal is not so straightforward. Various solutions have been explored to keep them in service and Honda Motor Europe, together with SNAM (Societe Nouvelle d’Affinage des Metaux), is investigating the possibility of using batteries in a ’second life’ for the storage of renewable energy in industrial applications.

SNAM is a battery recycling company and is increasing its role in partnership with the carmaker to advance the sustainable usability of its end-of-life battery packs. The pan-European arrangement will see SNAM collect and recycle batteries from Honda’s increasing number of hybrid and electric vehicles and either potentially prepare them for ‘second-life’ renewable energy storage uses or extract valuable materials for recycling if they are not suitable for that purpose.

Honda and SNAM have worked together since 2013 to ensure the traceability of end-of-life batterie packs and dispose of them in accordance with European Union environmental standards. The expansion of this agreement will see SNAM collect lithium-ion and NiMH batteries from Honda’s dealer network and Authorised Treatment Facilities in 22 countries, before analysing how suitable they are for recycling and processing them accordingly.

Second life applications

“As demand for Honda’s expanding range of hybrid and electric cars continues to grow, so does the requirement to manage batteries in the most environmentally-friendly way possible. Recent market developments may allow us to make use of these batteries in a second life application for powering businesses or by using recent improved recycling techniques to recover useful raw materials which can be used as feedstock into the production of new batteries,” said Tom Gardner, Senior Vice-President at Honda Motor Europe.

Safe and low carbon transport is utilised for the collection of used batterie packs. On arrival, SNAM assesses which battery packs are valid for inclusion in a new energy storage device. These are then repurposed and made available by SNAM for domestic and industrial applications.

When battery cells are damaged and unsuitable for ‘second life’ applications, materials such as cobalt and lithium can be extracted using hydrometallurgy techniques involving the use of aqueous chemistry. These can be reused in the production of new batteries, colour pigments or as useful additives for mortar. Other commonly used materials including copper, metal and plastics are recycled and offered to the market for use in the production of a variety of applications.

With activities in the auto industry having come to a standstill and people in many countries having to remain at home, it’s a good time for car enthusiasts to find out more about the history of their favourite companies. For Honda fans, there is ‘Honda Origins’, which retraces the life of company founder Soichiro Honda through an animated series combining Japanese-style manga cartoon drawings, audio and historic photographs.

The audio-visual journey from the beginnings of Honda through to its achievements and legacy is presented over 6 episodes each lasting between 10 and 20 minutes.

The series uses the original manga comic ‘Honda Soichiro Hon Den’, published by Shogakukan Inc., to interweave the founder’s life and unique philosophy on life and business with the evolution of the company from its origins to the successful multinational that it is today.

Click here to go to the Honda Origins video series

A story to pass on

The first episode of the series, ‘Bouncing Back’, tells how Soichiro Honda began after the Second World War to found the Honda Technical Research Institute in 1946 in the city of Hamamatsu. His journey towards motorisation started with a generator engine attached to a bicycle. This venture, together with Takeo Fujisawa, his partner, became the Honda Motor Company two years later in 1948.

The other chapters (A Dream is Born; Crisis on the Way to the Isle of Man Declaration; American Advance; Veni, Vidi, Vici: We Hate to Lose) describe key moments of his life and values, and the history of the company, making special reference to Honda’s commitment to motorcycles, cars and racing.

The last chapter in the series (Epilogue) recounts the company’s beginnings as a multinational through its expansion in the USA, and ends shortly afterwards with the joint retirement of the company’s two founders on the same day.

What is ‘success’?

One of the most important values highlighted in the series is perseverance and learning from failure; this is embodied by a quotation from Soichiro Honda that defines the spirit of the company: “’Success’ represents the 1% of your work which results from the 99% that is called ‘failure’”.

General Motors and Honda have agreed to jointly develop two all-new electric vehicles for Honda, based on GM’s highly flexible global EV platform powered by proprietary Ultium batteries. The EVs will be manufactured at GM plants in North America with sales expected to begin in the 2024 model year in North America.

Production of these Honda electric vehicles will combine the development expertise of both companies. The exteriors and interiors of the new EVs will be exclusively designed by Honda, and the platform will be engineered to support Honda’s driving character.

Joint pursuit of electrification

GM and Honda already have an ongoing relationship around electrification, which both companies are pursuing in this decade. This includes work on fuel cells and the Cruise Origin, an electric, self-driving and shared vehicle, which was revealed in San Francisco earlier this year. Honda also joined GM’s battery module development efforts in 2018.

“This collaboration will put together the strength of both companies, while combined scale and manufacturing efficiencies will ultimately provide greater value to customers,” said Rick Schostek, Executive Vice-President of American Honda Motor Co. “This expanded partnership will unlock economies of scale to accelerate our electrification roadmap and advance our industry-leading efforts to reduce greenhouse gas emissions.”

Related: GM Looking Forward To All-Electric Future With Ultium Batteries ![]()

According to Doug Parks, GM Executive Vice-President of Global Product Development, Purchasing and Supply Chain, the agreement builds on a proven relationship with Honda, and further validates the technical advancements and capabilities of our Ultium batteries and our all-new EV platform.

“Importantly, it is another step on our journey to an all-electric future and delivering a profitable EV business through increased scale and capacity utilization. We have a terrific history of working closely with Honda, and this new collaboration builds on our relationship and like-minded objectives,” he said.

As part of the agreement to jointly develop electric vehicles, Honda will incorporate GM’s OnStar safety and security services into the two EVs, seamlessly integrating them with HondaLink. Additionally, Honda plans to make GM’s hands-free advanced driver-assist technology available.

After 3 years in the Malaysian market, the Honda BR-V for 2020 gets a facelift to freshen its appearance with additional features for more convenience. Prices have not been announced but bookings for the model are now accepted at 100 Honda dealerships nationwide with deliveries to customers expected to begin before the end of this month.

Over 36,000 units have been sold nationwide which translated into a 45% market share in 2019, which helped the BR-V maintain its position as the leader in its non-national segment.

Honda Malaysia Managing Director & CEO, Toichi Ishiyama, said: “The BR-V was developed exclusively by Honda R&D Asia Pacific Co., Ltd. (HRAP) for the ASEAN market. It is also the first HRAP model in Malaysia. It caters to the increasing market demand for a 7-seater car that is spacious and versatile at the same time.”

“To continue offering high-quality products and meeting customer expectation, Honda Malaysia conducted market study and collected customer feedback that can help us understand our customers better. Armed with significant insight of the market, the New BR-V received exciting enhancements that are able to further captivate the hearts of Malaysians,” Mr. Ishiyama added.

The changes for 2020

The exterior of the BR-V has an updated front design with a new bumper, grille, lower bumper garnish and new front foglight garnish. There’s also a new rear lower bumper garnish, new shark fin antenna and the 16-inch alloy wheels have a new design as well.

For added convenience, the driver can now enjoy keyless entry and start/stop the engine with the push of a button. These are now standard features for both variants. New leather seat upholstery with a red accent is also introduced for a sporty touch.

No changes to the 1.5-litre SOHC i-VTEC engine are mentioned. This powerplant produces 120 ps/145 Nm, the highest output in its segment, giving the 7-seater BR-V brisk performance.

To locate an authorised Honda showroom in Malaysia, visit www.honda.com.my.

Click here for other news and articles about Honda.

At long last, the 10th generation Honda Accord has arrived in Malaysian showrooms. Although the new generation first went on sale in October 2017 (in the US market), it was only in March last year that the ASEAN version was launched in Thailand, followed by Indonesia. Malaysia, in spite of the diminished D-segment market, still continues to assemble the flagship model, which has been the case since the first generation in the late 1970s.

With the D-segment smaller in size here (prompting Edaran Tan Chong Motor to stop selling its Nissan Teana), Honda Malaysia plans to sell only 200 units a month – and that too is felt to be on the high side. We don’t have the sales figures for last year (as the powerful Competition Commission won’t allow the public to know) but the production numbers totalled less than 1,000 units with an average of 77 units/month.

Nevertheless, the Accord is popular in markets like America (where it has been the overall bestselling passenger car) and so there is still enthusiasm in product development. And since the third (current) Jazz generation that appeared in 2014, Honda’s styling has become more and more aggressive and sporty, with the Accord now also following the same themes.

Some may regard the new styling, with a coupe-like rear end, as being too radical a change for a model in this upper segment. After all, cars like the Accord have usually been driven by older people with more senior positions in the corporate world. These are people who may have conservative tastes and the new looks might not go down well.

But Honda has always been a maverick in the car industry and daring enough to embark in new directions. The older management may have their conservative views but it appears that they are also open to evolving trends and willing to trust their younger designers to head in the right direction.

Comparing the latest 10th generation to the first one that started off as a hatchback in 1976 is like comparing day and night. The differences are so great that it’s hard to believe they share the same nameplate. The first generation sedan was 4.45 metres long and today’s Accord is 500 mm longer, with a wheelbase that is almost similarly longer with the 55 mm increase for the 10th generation. It’s also heavier – that first Accord weighed just 965 kgs whereas the 2020 one is almost 1,500 kgs.

Powertrains have greatly changed too. Until this generation, the smallest engine for the Accord was the 1.6-litre unit used in the early generations. But in this age of downsizing, small is better and so the new Accord gets its smallest engine ever – the 1.5-litre turbocharged Earth Dreams Technology engine.

It’s a bold move to have such a small displacement engine for such a big car although European motorists are fine with it. Malaysians still think of cc as being indicators of output and performance and we won’t be surprised if salesmen are asked ‘Can go up Genting Highlands or not?’, referring to the hill resort area with steep slopes. Younger customers may already accept and understand that with turbocharging, the output can be boosted and performance can be much higher.

In fact, the new Accord’s engine (with VTEC) develops 201 ps/260 Nm, considerably more powerful than the 2.4-litre engine. And apart from all that extra output is the fact that, along with the assistance of the CVT, fuel consumption will be lower and you also pay much less roadtax.

The Accord range in America has the additional option of a bigger 2-litre (K20) engine as well as a hybrid variant (also available in Thailand) but for the Malaysian market, it is banking on the 1.5-litre turbo engine only. Understandably, with the low volumes, it would make no sense to assemble two different engine variants and in any case, the other variants would cost more.

As an all-new generation, the latest Accord is essentially a clean-sheet development meaning it started almost more scratch rather than having a structural carry-over. The platform is new to accommodate the largest bodyshell the model has ever had. It is now 4901 mm long (+39 mm), 1862 mm wide (+13 mm) and though it looks low-slung because of the sleek profile, the roof is actually 16 mm higher. A 54 mm increase in the wheelbase extends it to 2830 mm, with 48 mm more rear legroom as a result of that increase.

During the development of the new Accord, the engineers worked hard at bringing down NVH (noise, vibration and harshness) as this influences the perception of quality and refinement. Spray foam helps to lower noise while High-Performance Adhesive enhances rigidity which improves durability. Laser brazing is used to join the roof and body side panels, and Honda Malaysia’s factory in Melaka had to agree to make the necessary investment for equipment to do this process before Honda was willing to allow the model to continue to be assembled here.

Having been launched almost a year ago in Thailand meant that ASEAN NCAP could evaluate the new Accord and not unexpectedly, it got the maximum 5-star rating. Passive safety apart, the new Accord also has an impressive list of active safety systems and features that will help the driver to avoid accidents or reduce the effects of accidents on the occupants.

Much of this is provided by the Honda SENSING system, an integrated package of systems with 8 components. These are Low Speed Follow, Auto High-Beam, Adaptive Cruise Control, Collision Mitigation Braking System, Forward Collision Warning, Lane Keep Assist System, Road Departure Mitigation, and Lane Departure Warning. Most of the systems rely on information from a camera mounted at the top of the windscreen and a millimetre-wave radar in the grille.

With Adaptive Cruise Control (which can operate down to 0 km/h) and the Collision Mitigation Braking System that will automatically apply the brakes, drivers can have an early experience of autonomous motoring as these systems are managed by a computer without involvement of a human.

Additionally, there’s the Honda LaneWatch system, an innovative idea which uses a small camera in the left door mirror to capture real-time images of that side of the car. The image is displayed on the screen in the middle of the dashboard, which the driver can see more easily than having to swivel the head to the left. Also providing additional visual coverage is a Multi-View Camera System.

Parking the car is made easier with Smart Parking Assist System with Brake Assist (Rear) that recognises the border line of the parking space and assists the driver with automatic steering assist, screen display, voice guidance and auto braking.

As with other Hondas currently in showrooms, the new Accord’s interior was packaged with the ‘Man-Maximum, Machine-Minimum’ approach. Being the flagship model, it comes with a comprehensive list of premium features that include 4-way Assistant Power Seat with Shoulder Switch, and Wireless Charging.

The instrument panel and dashboard have elements of the previous generation but enhanced with more premium and fresher looks. For example, there is a bright and clear 8-inch Advanced Display at the centre console and a 7-inch Interactive Thin Film Transistor (TFT) meter cluster.

As with the latest Civic, the new Accord also comes with a 5-year unlimited mileage warranty and free labour service (terms and conditions apply). It is now available for viewing and test-drives at authorised Honda dealerships nationwide. To locate a showroom near you, visit www.honda.com.my.

© Copyright – Piston.my 2024 Trademarks belong to their respective owners. All rights reserved