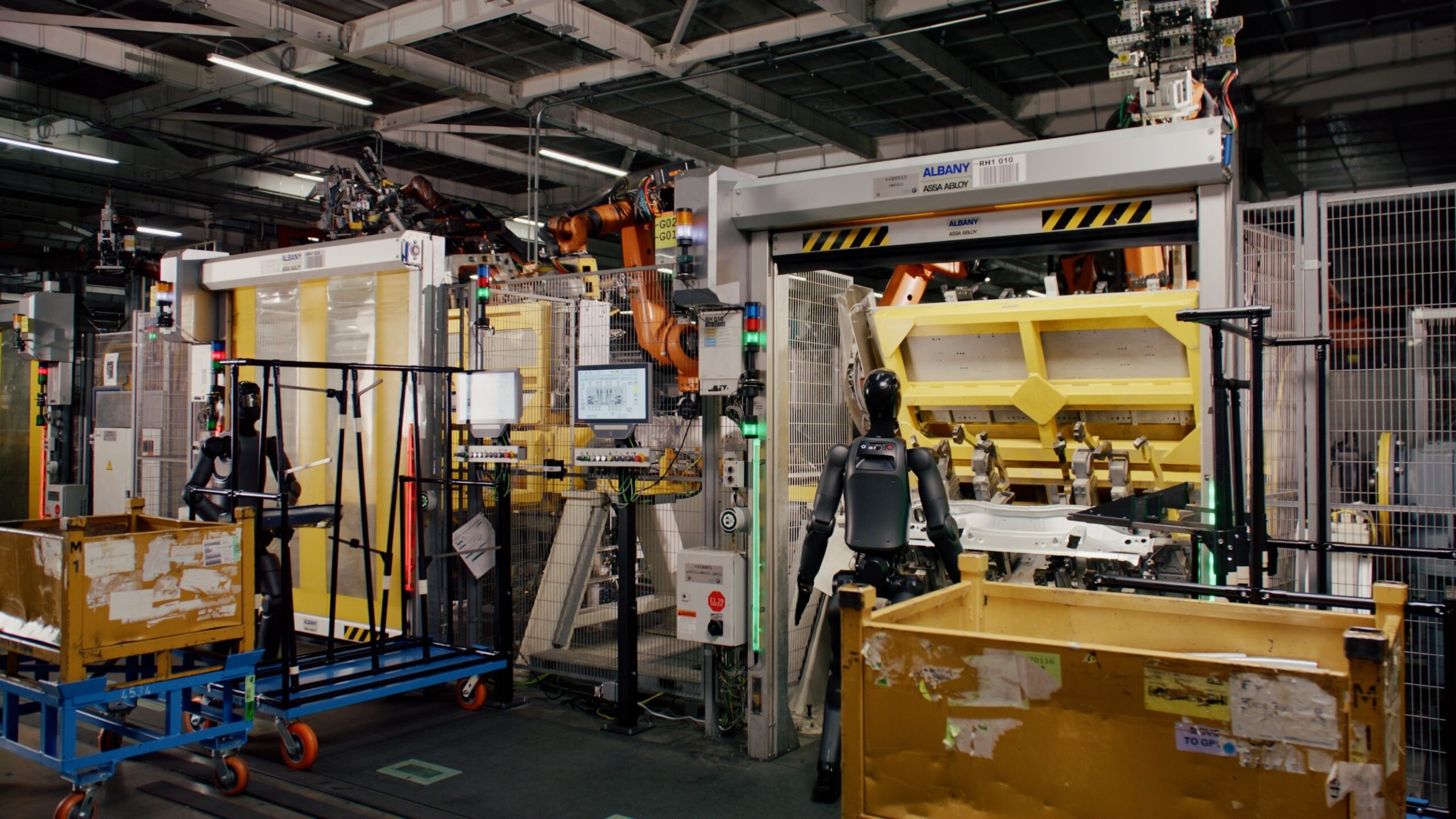

The BMW Group continues to lead the way in production innovation with the advancement of Automated Driving In-Plant (AFW) technology as part of its BMW iFACTORY framework. Following successful pilot tests since 2022, the AFW project has now entered series operation, beginning at the company’s largest European plant in Dingolfing.

The system leverages advanced digitalisation and automation, enhancing production efficiency and logistics. After the launch in Dingolfing, BMW’s Leipzig plant is set to adopt this cutting-edge technology, with other facilities in the production network slated to follow in phases.

Revolutionising Plant Operations with Automation

The AFW technology enables new BMW and Mini vehicles to drive autonomously through designated routes within the plant. For example, in Dingolfing, vehicles travel autonomously over one kilometre from assembly halls through the “short test course” to the finishing area.

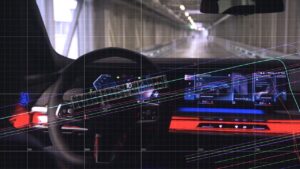

Key to this innovation is the extensive LIDAR infrastructure, the largest in Europe, supported by state-of-the-art cloud architecture. This system, developed in collaboration with Swiss startup Embotech AG, ensures smooth and precise movements of vehicles, regardless of their equipment configurations.

Expanding Automation Across BMW Facilities

- Dingolfing: Successfully implementing AFW for BMW 5 Series and 7 Series models.

- Leipzig: Expanding to Mini Countryman and other BMW models, targeting 90% automation of vehicle movements.

- Regensburg and Oxford: Set to adopt AFW by 2025.

- Debrecen, Hungary: Launching the technology with the commencement of series production at the new site.

Future Applications and Developments

BMW plans to extend the use of AFW beyond in-plant operations, including:

- Automated vehicle driving through testing zones.

- Autonomous movement in outdoor distribution areas.

The development team is also exploring integration with on-board vehicle technology, which will work in tandem with external sensors to enhance efficiency.

Setting Benchmarks for Autonomous Driving

The AFW project represents BMW Group’s commitment to pushing the boundaries of automation and digitalisation. Over the next decade, BMW plans to log millions of test kilometres with AFW technology within its global production network.

This pioneering step further cements BMW’s position as an innovation leader, transforming its production facilities into hubs of advanced technology and operational excellence.