With the VISION 7S concept, Skoda is providing a preview of an all-new battery electric SUV as well as the Czech brand’s new design language. There is also a new brand logo which no longer uses sculptural 3D graphics, a response to a growing shift in marketing activities from print to online.

The 7-seater VISION 7S SUV, which is 3 to 4 years from appearing in Skoda showrooms, sits on the Volkswagen Group’s Modular Electrification Kit (MEB). Proposed with an 89 kWh battery pack, it has a projected range of over 600 kms.

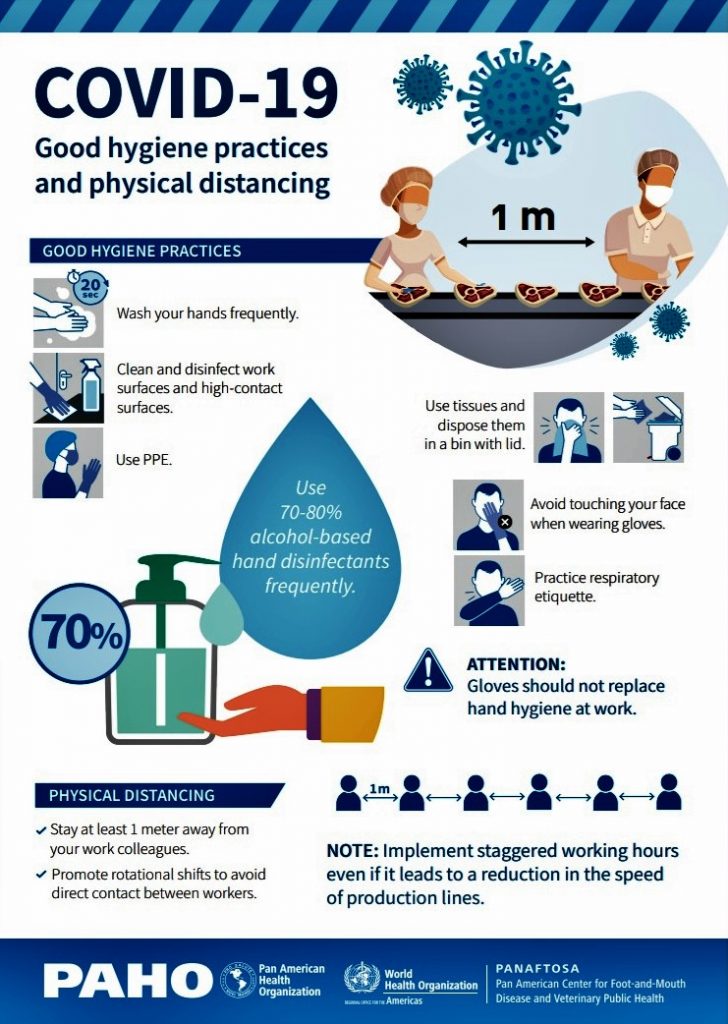

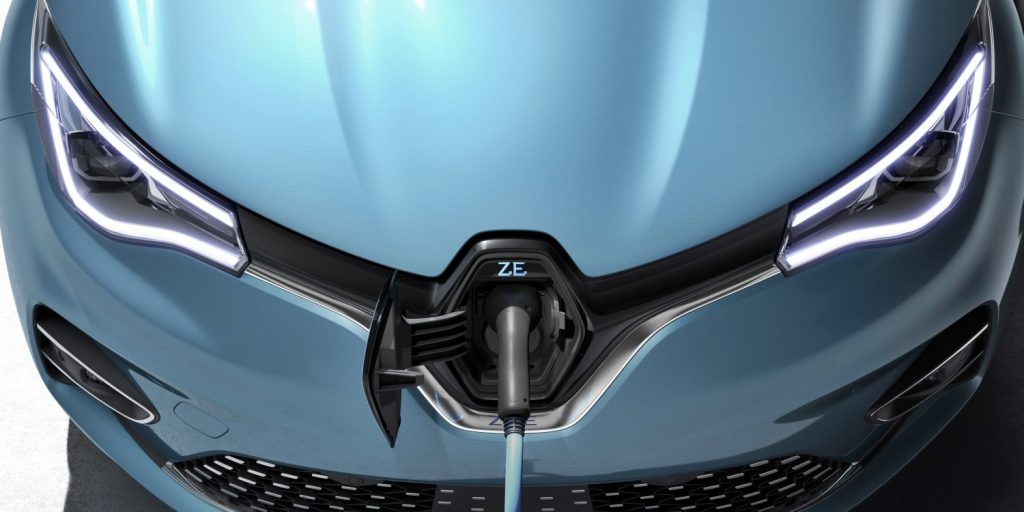

With the new design language comes the ‘Tech-Deck Face’ at the front end with a a solid underbody and aerodynamic roof lines. The Tech Deck Face embodies a modern reinterpretation of the familiar Skoda grille. Though it has similar lines, the appearance is significantly flatter and wider than the previous styling. The ribs have been replaced by dark glass that conceals the vehicle’s sensors.

The redesigned SKODA wordmark replaces the brand’s picturemark and is complemented by a new ambient light strip. This extends across the entire width of the vehicle at the upper edge of the front section and features illuminated graphics.

The robust bumpers are made of durable, recycled tyres. This material is also used for the wheelarch linings and adds a rugged visual highlight. Seven vertical air intakes are integrated into the front, through which air is directed to the cooling systems and brakes, and another nine vertical air outlets are in the rear bumper.

A control element in bright Flashy Orange is located in the centre of both the front and rear. These can be pulled out to serve as hooks. In addition, they can be used to safely cut off the vehicle’s high-voltage current from the outside, if required.

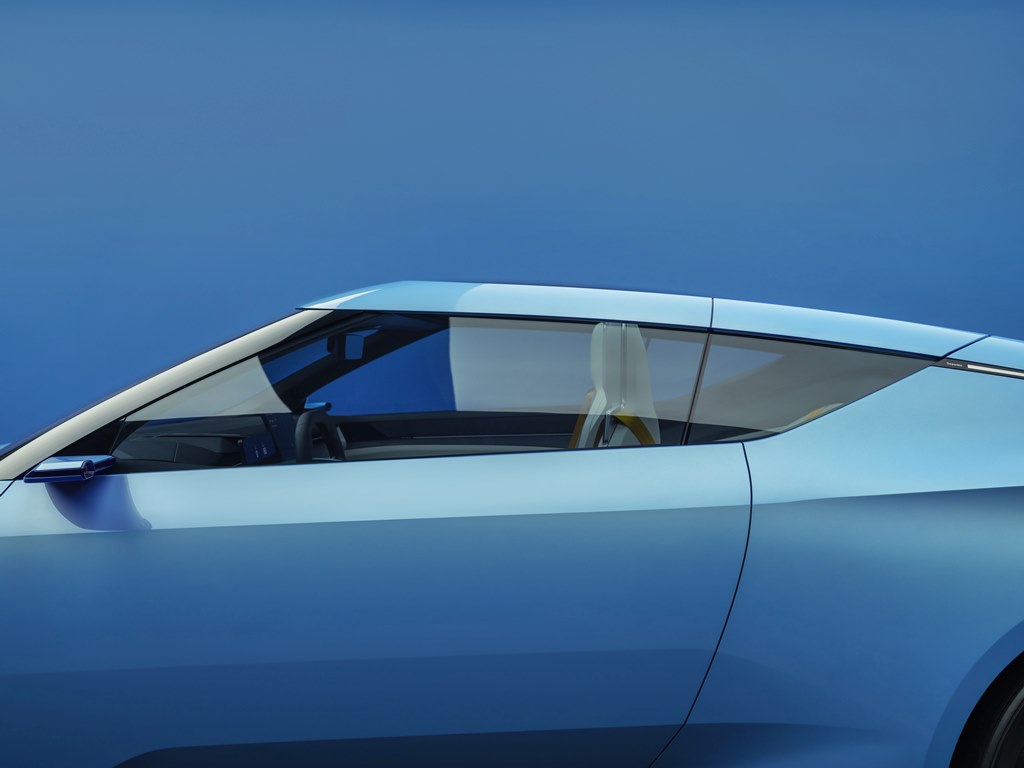

A high tornado line separates the solid underbody from the side windows and emphasises the powerful shoulder sections through its curve. The squared-off wheel arches beneath it are prominent and clearly recessed. Within them, the wheels are aerodynamically optimized rims and almost completely closed.

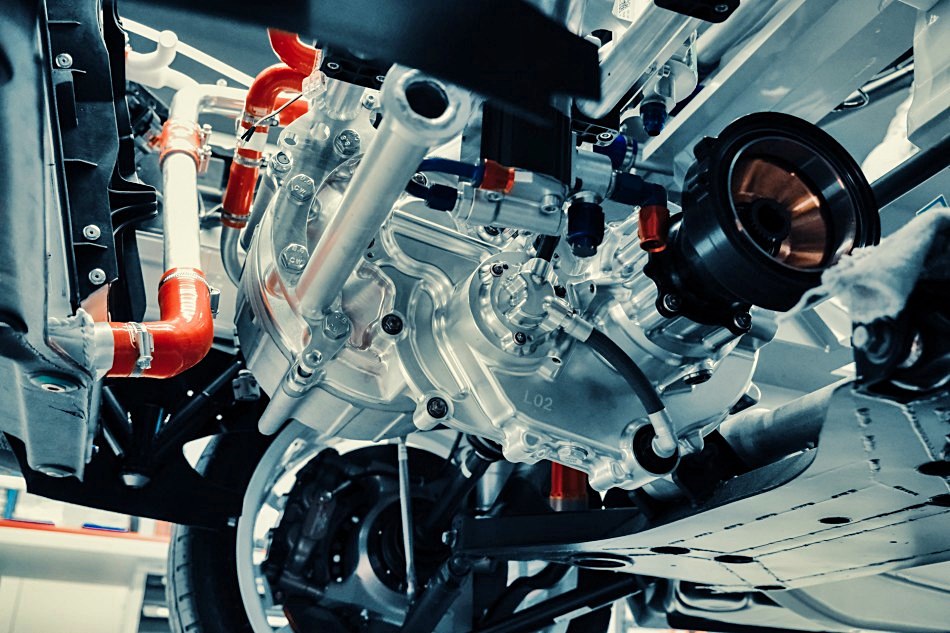

Additional air outlets are positioned between the wheel arches and above the side skirts. These act as running boards for the portal doors that swing up in opposite directions and also have cover grilles. These grilles channel the warm air generated from cooling the high-voltage battery pack to the outside.

The flat roofline gently slopes to the rear and merges with a pronounced roof spoiler for high aerodynamic efficiency. The triangular D-pillar extending to the rear features a bold design; at the bottom, it bears the new SKODA wordmark, which also appears on the tailgate and is lit up in the same way as at the front of the vehicle.

The minimalistic interior is as spacious as the exterior proportions of the Skoda concept suggest. The sense of security further enhanced by the combination of dark and light materials. These are leather-free (mostly from sustainable sources) and are extremely durable, thanks to some smart material combinations.

One example is the floor, which is also made from recycled tyres. The interior trim is also sustainable and coated with a fine, matt metallic layer, thus conserving valuable resources. The fabrics are made of 100% recycled polyester yarns.

Great emphasis was placed on further optimising usability. In addition, the vehicle’s menu structure and infotainment functions have been streamlined, and the controls on the central, free-standing touchscreen, as well as haptic keys for important or frequently used functions, are particularly intuitive.

In front of the central screen on the instrument cluster is a large crystal that indicates the battery and charging status using different colours. This can be seen easily from outside the Skoda SUV.

The position of the childseat may seem unsuitable from the safety point of view but it is actually in the safest place in the vehicle. It is integrated into the centre console, which extends to the second row of seats, opposite to the direction of travel. This means the child is optimally protected, and the passengers in the second row can always keep an eye on him or her.

An optional interior camera in the rear roof area can also transmit a video of the child to the central infotainment display. This makes it possible for the driver and front passenger to see the little ones on board at all times.

The VISION 7S also introduces a new series of ‘Simply Clever’ features, well known in Skodas. For example, the air vents on the dashboard work in a discreet, diffuse mode until more direct ventilation is needed. Passengers will also find magnetic surfaces under the floating centre console, where metal Skoda drink bottles or a first-aid kit can be securely attached. There are also backpacks that are magnetically attached to the seat backrests, easily taken off when leaving the vehicle for a hike.

“The VISION 7S is the forerunner of our new design language that we’ll be rolling out across the entire product portfolio over the coming years. We’ll also be using it to sharpen our customer appeal; with the new styling, we are taking the brand to the next level and aligning it to our customers’ new needs and expectations, particularly regarding UX (user experience), connectivity and the entire customer journey,” said Martin Jahn, Skoda Auto Board Member for Sales and Marketing.