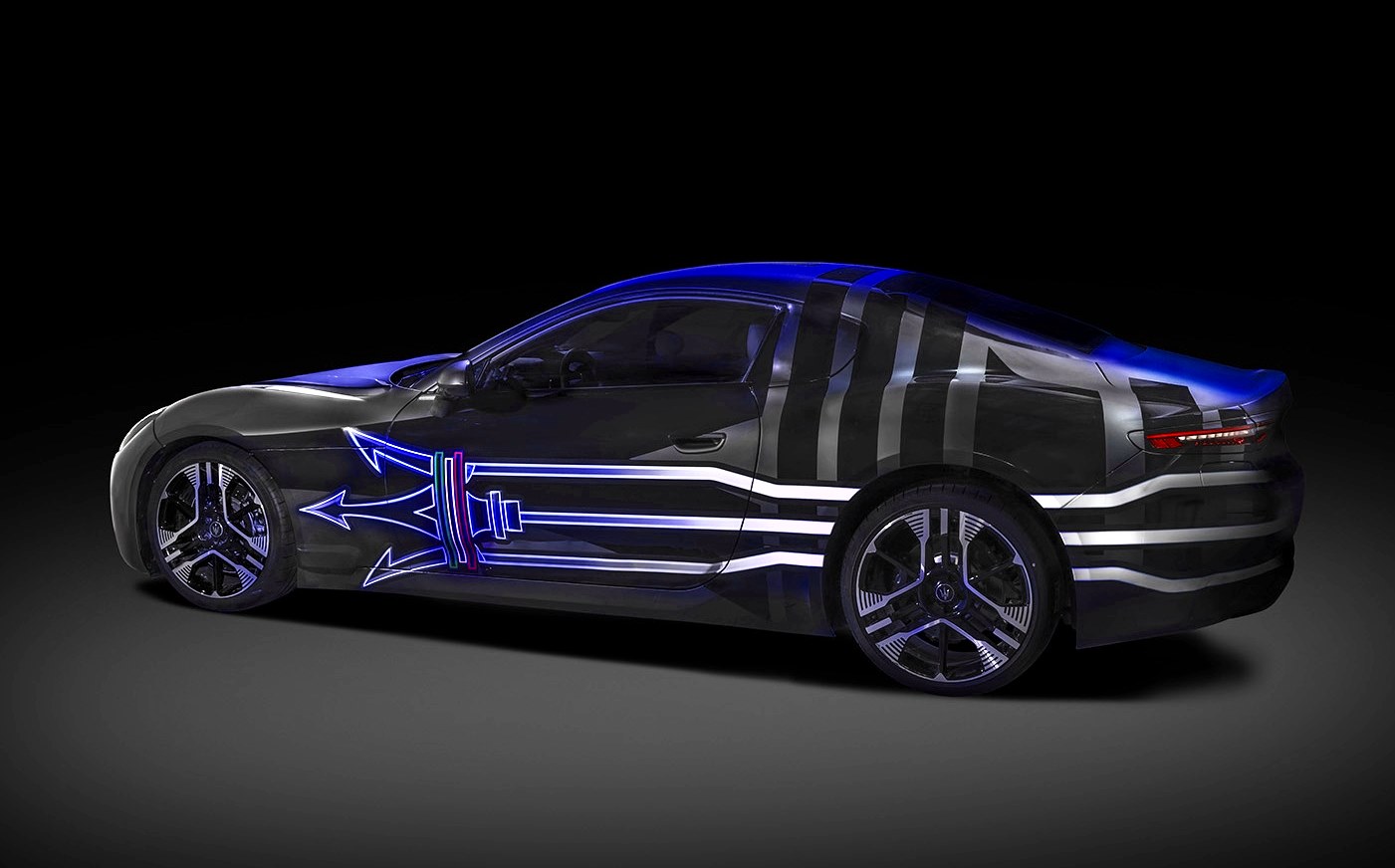

Lexus began its electrification journey back in 2005 with the RX400h hybrid, followed by hybrid variants of other models as well as the CT-200h, which was only available with a hybrid powertrain. Today, with the world premiere of the new RZ 450e, Toyota’s luxury brand begins a new era of battery-electric vehicles (BEVs) and the Lexus Electrified vision.

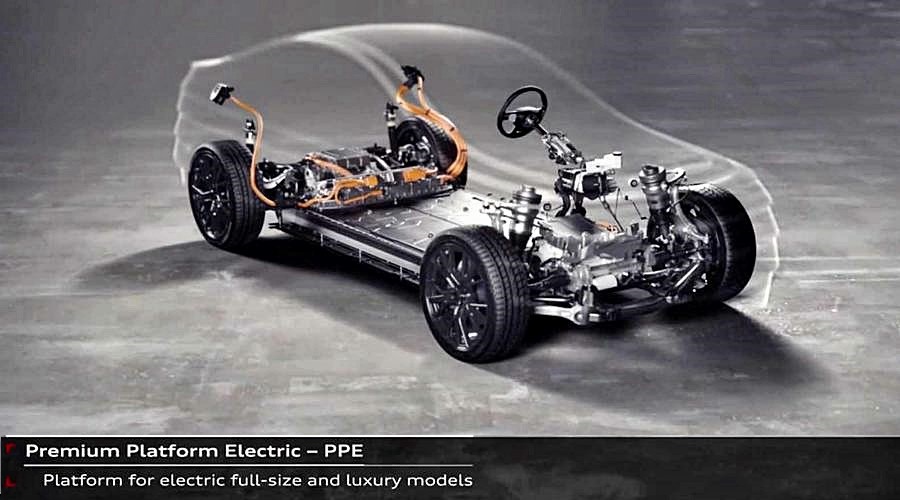

As the brand’s first BEV built on a dedicated platform, the RZ heralds the transition of Lexus into a BEV-centred brand. Besides a brand new design, it also offers advanced electrification technologies developed over many years of hybrid vehicle development.

New visual identity for BEVs

The exterior design presents a new visual identity as the familiar spindle grille is replaced by a minimalist BEV Spindle Body which focuses on aerodynamic efficiencies, optimized proportions, and style, versus serving the cooling and exhaust needs of an internal combustion engine. The rear features the spelled-out LEXUS logo as part of a clean and simple horizontal design that highlights the wider rear track while above is a distinct roof spoiler.

The interior is likewise minimalist, with an airy and luxurious environment that Lexus has long been known for, along with high-quality craftsmanship. Based on the tazuna concept, the cabin advances the human-centred philosophy of Lexus by welcoming occupants with intuitive controls oriented around the driver, ensuring maximum concentration on driving.

New steering wheel design

The application of shift-by-wire has resulted in a Lexus-first dial shift knob mounted on the centre console. More eye-catching will be the compact yoke-like steering wheel which is said to greatly reduce the driver’s workload by eliminating the need for hand-over-hand operation (eg in u-turns and parking). It also enabled the designers to lower placement of the instrument panel for better forward vision.

The RZ’s long wheelbase of 2850 mm within an overall body length of 4805 mm provides spacious rear-seat accommodation. An electronic ‘e-latch’ system is used to operate the doors while highly efficient Lexus-first electric radiant heaters, combined with a heat-pump system, ensure passenger ambient comfort. Three types of seat materials are used, including Ultrasuede, a refined material that uses 30% bio-based sustainable materials.

Overhead, some variants have a panoramic roof which is designed with heat shielding, thermal insulation and 99% UV protection. The glass also has a Lexus-first dimming function which, without a physical curtain, can instantly block light according to the needs of the occupants.

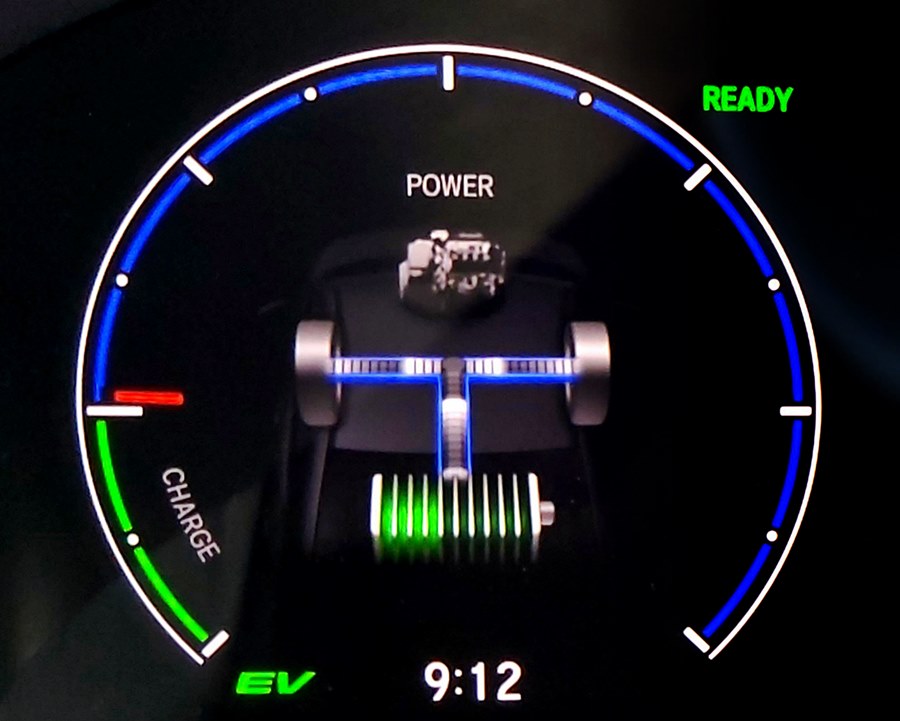

Different challenges for quietness

Quietness has been a hallmark of Lexus models since the very first one and besides generous use of high quality insulation, the engineers have also looked for the sources of noise and eliminated them. With the RZ powered by electric motors, new challenges were presented to the engineers who had to create a balance between sound generation and a very quiet interior space.

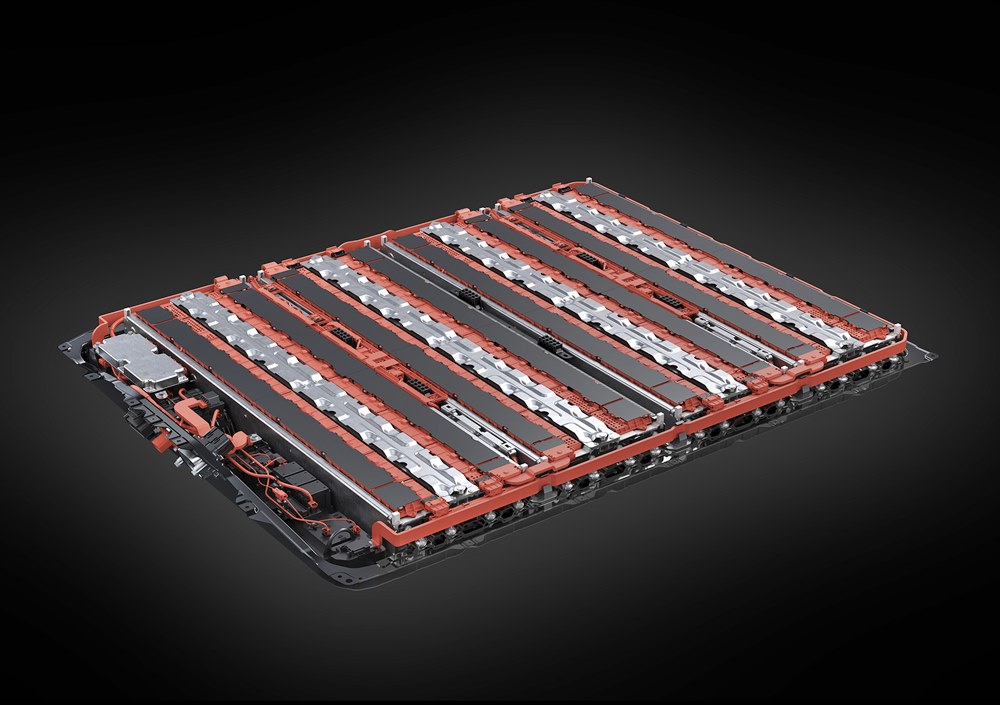

The underfloor battery functions as a sound barrier, the bonnet perimeter is sealed to eliminate noise caused by turbulent airflow. and acoustic glass suppresses other unwanted sounds. Additionally, the engineers have tuned sound frequencies to the vehicle’s speed and sound levels during dynamic actions such as acceleration.

Lexus Driving Signature

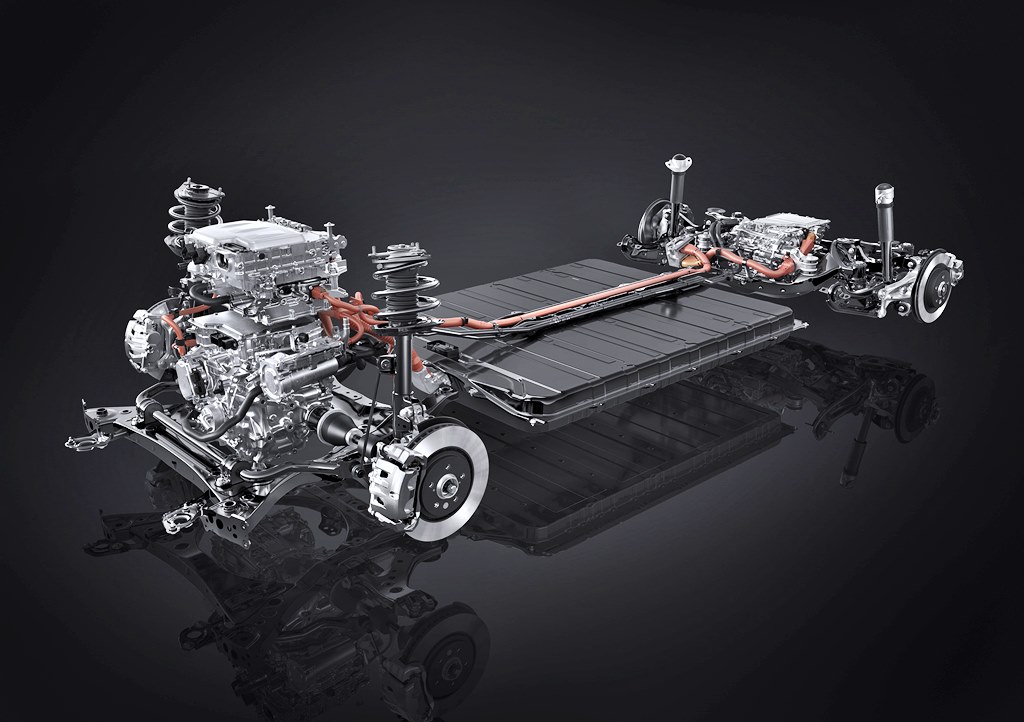

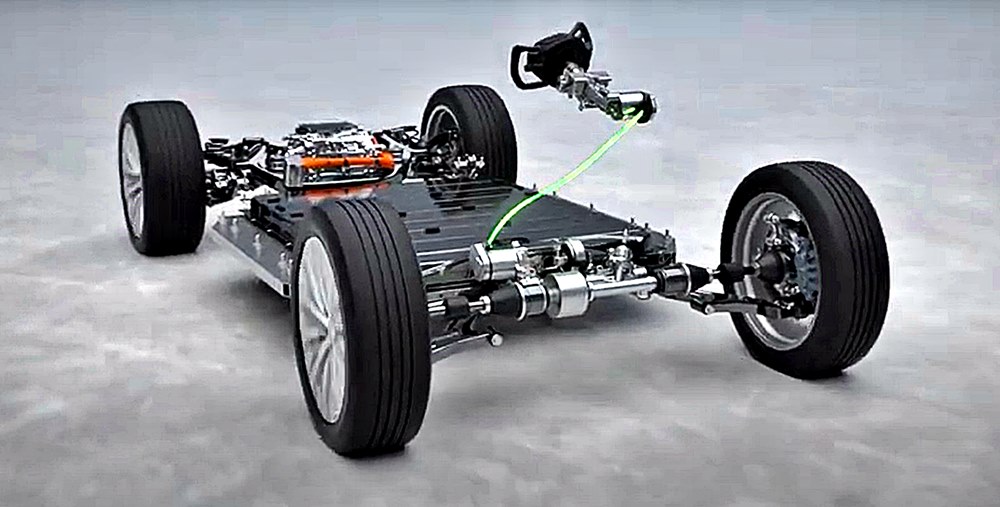

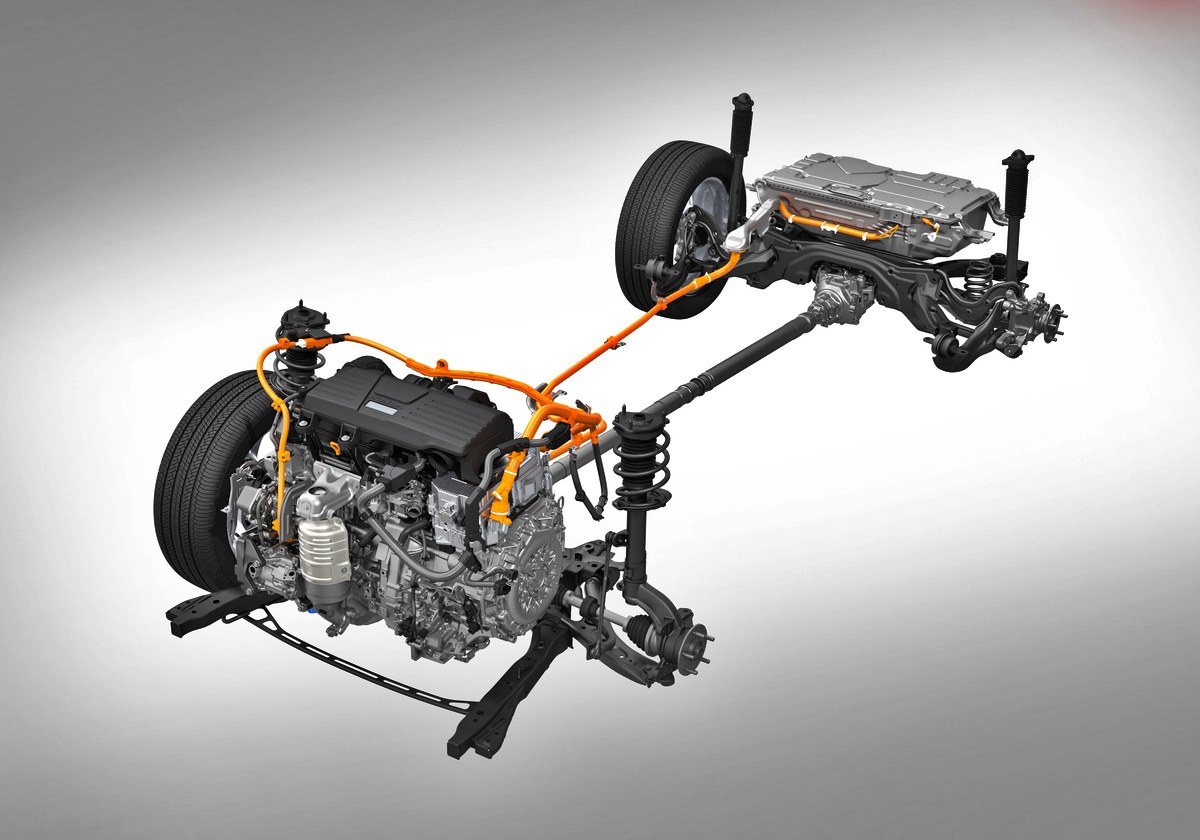

Regardless of the type of powertrain, the Lexus Driving Signature of impressive fundamental acceleration, steering and braking performance must be present. The electric powertrain system uses a front and rear e-axle, each equipped with a high-torque electric motor, transaxle and inverter in a compact unit. As each motor (front: 150 kW, rear: 80 kW) is directly connected to the wheels by a single driveshaft, power transmission is instantaneous.

The new DIRECT4 system takes the Lexus Driving Signature to an even higher level. It uses acceleration, cornering-speed and steering-angle information to automatically adjust front-rear torque delivery and braking force to all four wheels. The system uses a front-to-rear drive-force ratio between 60:40 and 40:60 for minimum vehicle pitch.

When the steering wheel is turned, drive force is biased to the front wheels between 50 and 75% for nimble response and excellent steering feel. When exiting a corner, torque distribution to the rear wheels is increased to between 50 and 80%, ensuring ample traction while controlling vehicle pitch.

Steer-by-wire

A Lexus-first steer-by-wire system contributes to enhanced vehicle manoeuvrability while blocking out unnecessary vibrations from the tyres and brakes. Optimum steering-gear ratios provide nimble and agile performance on winding roads and high-speed stability on highways.

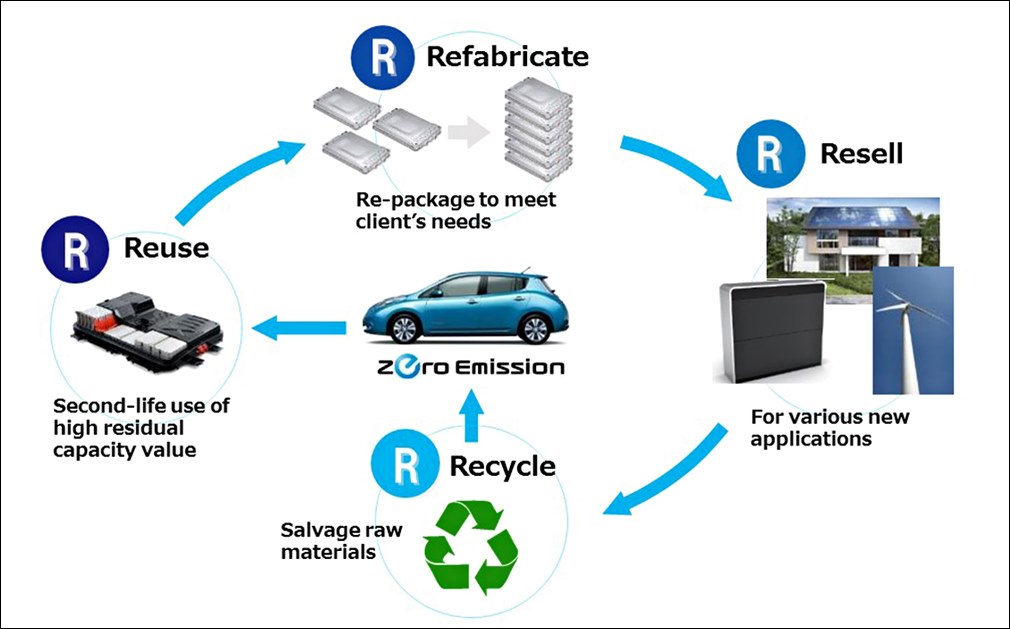

Long experience in battery technology

Toyota’s experience in developing ever better hybrid electric technology has also included advancing battery technology. Some of the advanced technologies are the high-capacity 71.4 kWh lithium-ion battery packs, Lexus-first silicon carbide elements in the inverters and the incorporation of low-loss technologies to deliver an estimated single-charge cruising range of 450 kms.

Battery-control technology ensures a world-class battery capacity retention rate claimed to be at least 90% after 10 years. Contributing to the long life with even higher battery capacity is a timer charging function that avoids over-charging.

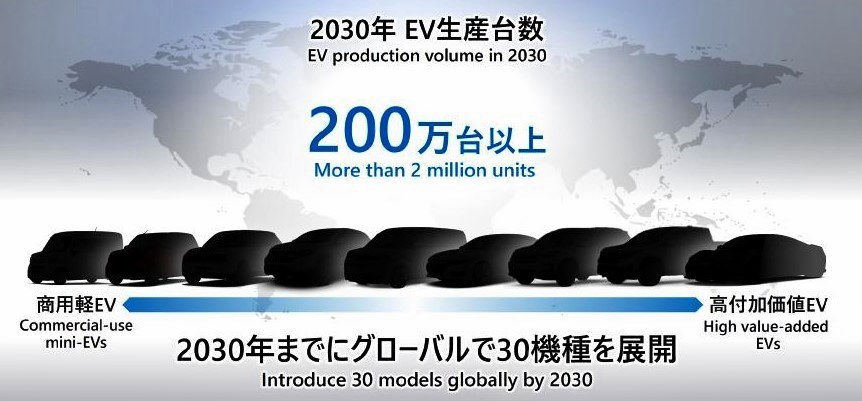

100% BEVs globally by 2035

Pricing has not been announced yet but exports of the RZ 450e, which will be made in Japan, will begin during the fourth quarter of 2022. In the years following till the end of the decade, Lexus will introduce entirely new BEVs covering every segment. By 2035, the brand expects to be selling only BEVs globally and fully contribute to the Toyota Group’s objective of carbon neutrality.