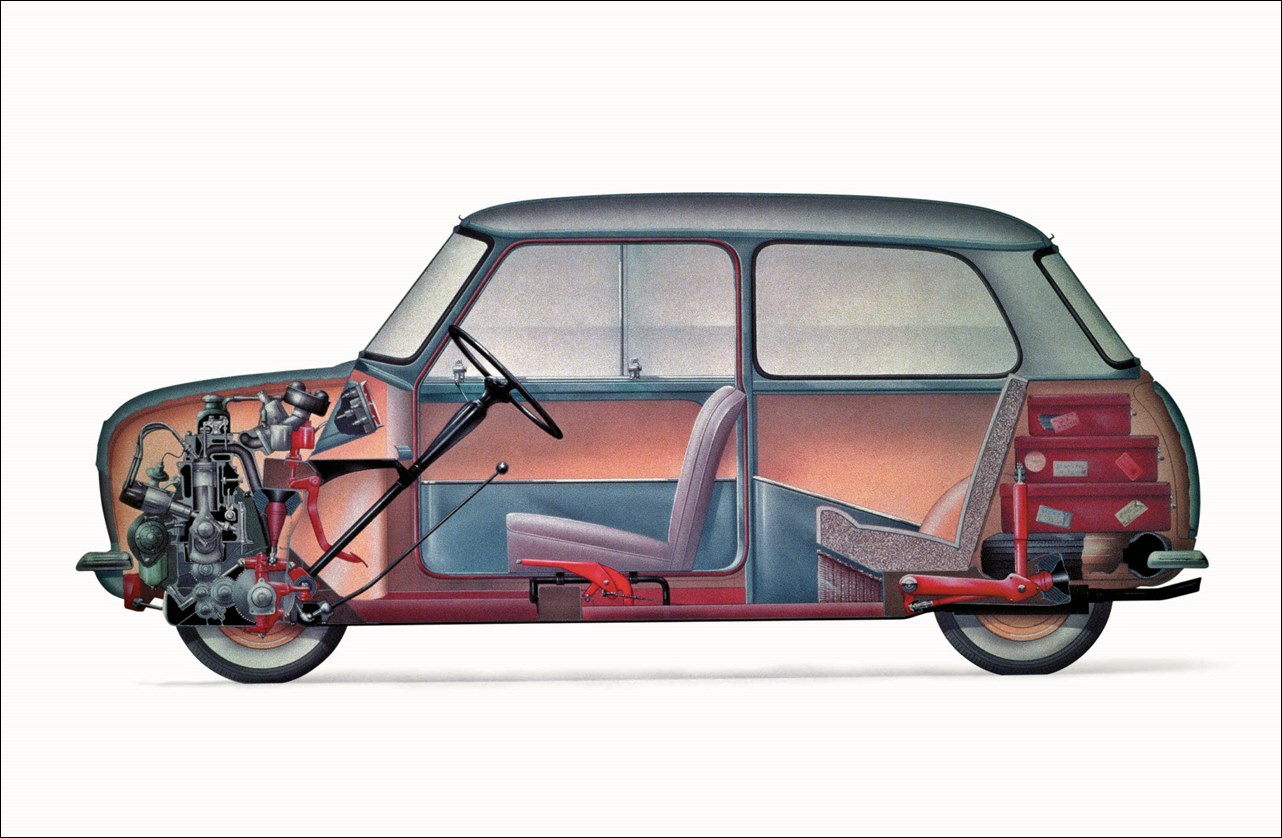

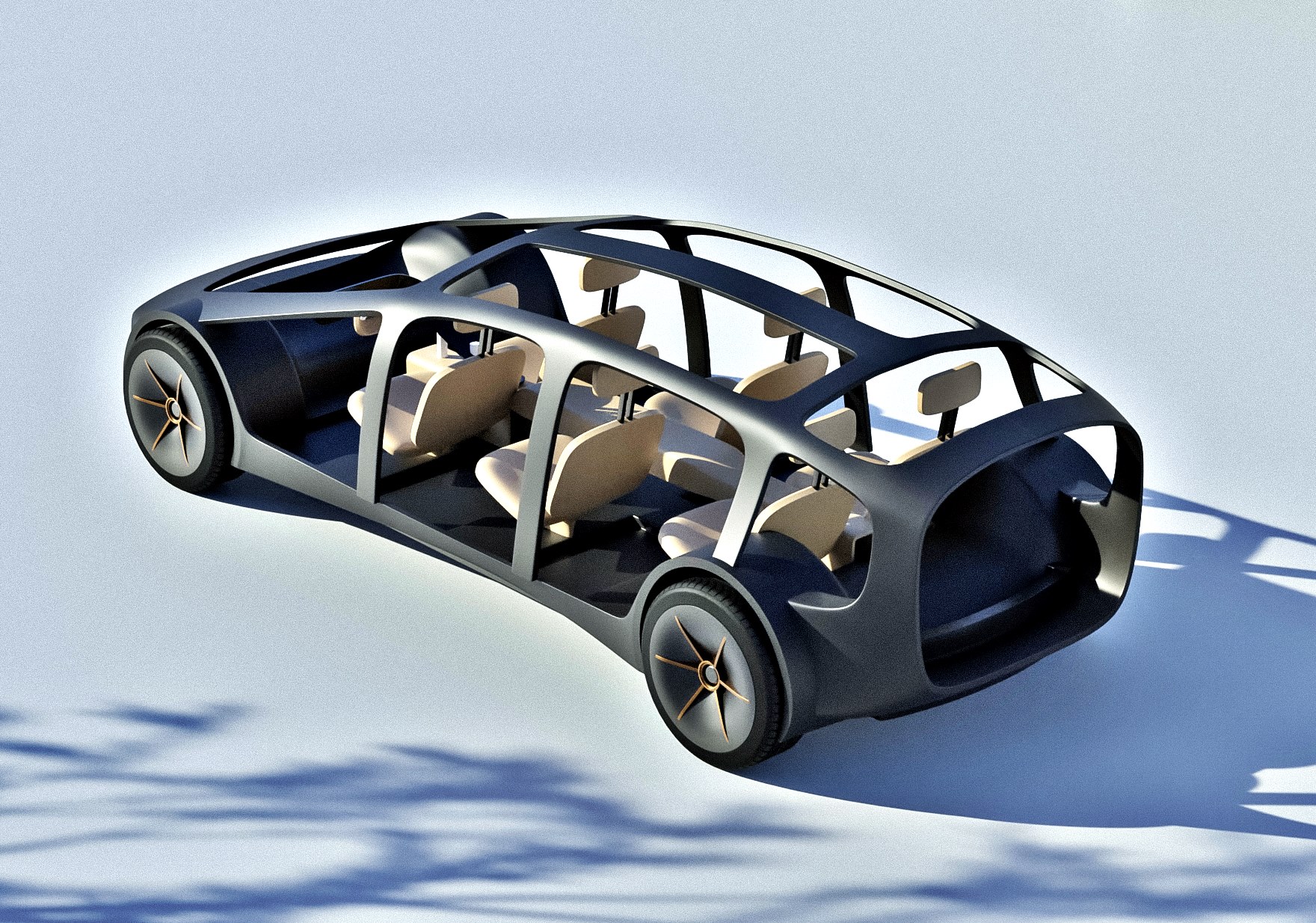

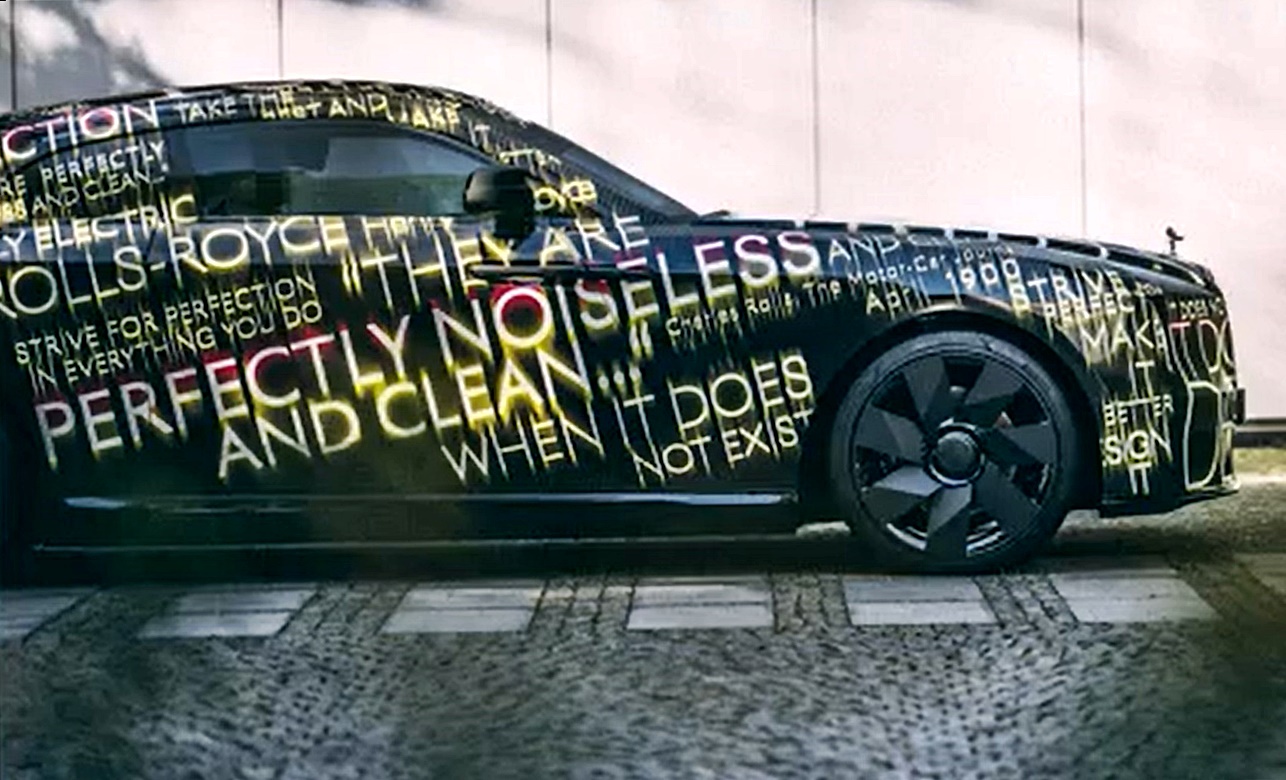

Next year, Rolls-Royce will unveil Spectre, its fully electric limousine that will go on sale in 2024. The final form that the car will have would have been approved so much work would have been done in the wind tunnel to make it as aerodynamically efficient as possible. For electric cars, this is vital to minimise the power used to overcome wind resistance and achieve high performance.

Wind tunnel studies cover every centimetre of the bodywork and even the tiniest details need to be shaped correctly for minimum wind resistance. This includes the iconic Spirit of Ecstasy figurine that stands on the edge of the bonnet. She will also grace the bonnet of the Spectre and after 111 years since being registered as intellectual property of Rolls-Royce, the Spirit of Ecstasy is being remodelled again.

The figurine has been remodelled with a lower, more dynamic stance that brings her much closer to the drawings made by her original creator, the illustrator and sculptor Charles Sykes, in the early years of the 20th century. It also sees her physical form represent ‘The Expression’, a visual device that forms part of the marque’s new visual language.

The new Spirit of Ecstasy stands 82.73 mm tall, compared to her predecessor’s 100.01 mm. Her robes, which flow behind her in the slipstream (often but incorrectly characterised as ‘wings’) have been subtly reshaped to make them more aerodynamic and realistic.

The most visible change is her stance. Previously, she has stood with her feet together, legs straight and tilting at the waist. Now, she is a true goddess of speed, braced for the wind, one leg forward, body tucked low, her eyes focused eagerly ahead.

These changes have both practical and stylistic benefits, contributing to the Spectre’s aerodynamic properties which Rolls-Royce says will be remarkable. The earliest Spectre prototypes have already shown a drag coefficient of just 0.26 Cd, making it the most aerodynamic Rolls-Royce ever created. The figure is expected to improve during the product’s exhaustive testing protocols undertaken in the course of this year.

This new expression captures the essence of Charles Sykes’ original drawings, but rather than simply being ‘redrawn’ or ‘redesigned’, her new shape has been digitally sculpted by a computer modeller working at the Rolls-Royce, who has a passion for life drawing and sculpture. Their experience in this field was invaluable in developing the figurine’s elegant lifelike facial features as well as her expression, which deftly combines focus and serenity.

The designers also consulted stylists at Roll-Royce for their perspective on her hair, clothes, posture, and expression, adding an authentically contemporary aura to her dynamism and commanding presence.

While all figurines are made using one of the oldest known casting techniques, named ‘lost wax casting’ or ‘cire-perdue’, each is individually finished by hand, so will be minutely different from figurine to figurine. As well as continuing a long Rolls-Royce tradition – until 1939, the mascots were made and polished by Charles Sykes himself – this subtle, ephemeral human element creates an intriguing contrast to the precise, highly engineered motor car she sits atop.

Though relatively rare in the modern era, changes to the Spirit of Ecstasy have been made throughout her 111-year lifespan. She has been rendered in various sizes and materials and, briefly, in a kneeling position. The new version created for the Spectre will appear on all future models. The current design will still be used on Phantom, Ghost, Wraith, Dawn and Cullinan and their Black Badge alter egos where applicable.

“The Spirit of Ecstasy is the most famous and desirable automotive mascot in the world. More than just a symbol, she is the embodiment of our brand, and a constant source of inspiration and pride for the marque and its clients. Like our brand, she has always moved with the times while staying true to her nature and character. In her new form she is more streamlined and graceful than ever before – the perfect emblem for the most aerodynamic Rolls-Royce ever created, and for gracing the prow of our bold electric future,” said Torsten Muller-Otvos, CEO of Rolls-Royce Motor Cars.

Leading every Rolls-Royce for 110 years – the Spirit of Ecstasy