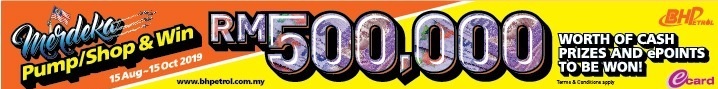

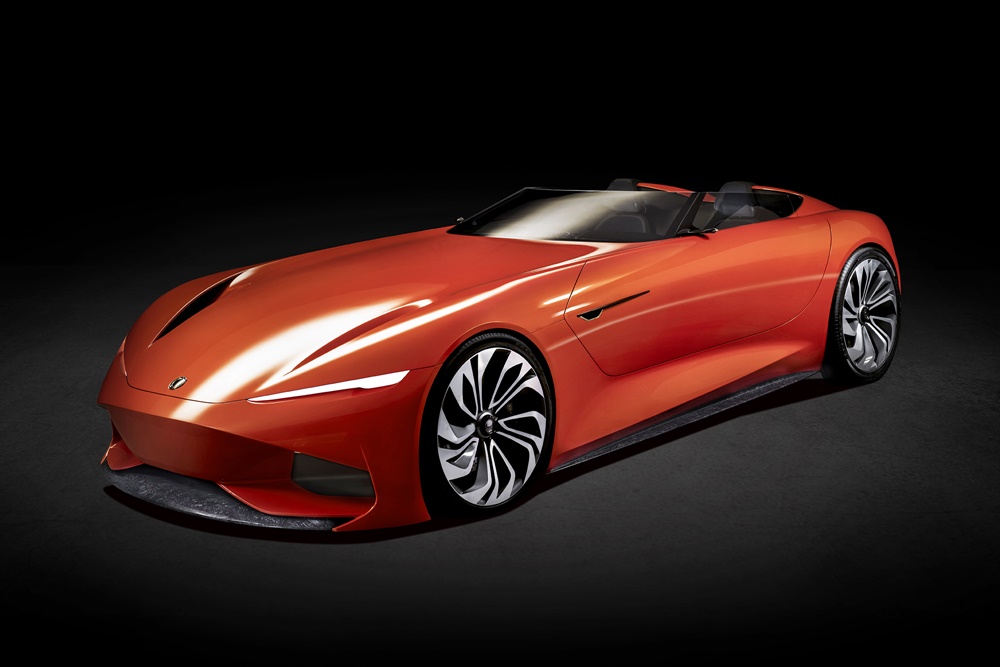

Karma Automotive, the company created from the previous Fisker Automotive purchased by a Chinese autoparts supplier Wanxiang Group, will reveal its design and technological direction with the North American debut of its SC1 Vision Concept car.

“The SC1 is a signpost to Karma’s future,” said Karma CEO Dr. Lance Zhou. “Designed and engineered in less than 12 months, SC1 is a full battery electric vehicle (BEV) that explores the brand’s striking design language and the innovative technology integration possible through our collaborative Open Platform strategy.”

Humanized communication system

The SC1 Vision Concept seamlessly integrates a new infotainment architecture with 5G connectivity and a humanized communication system with touch, voice, eye and graphical interfaces. Artificial Intelligence understands conventional language and commands, while a camera-based eye tracking system is capable of biometric identification, allowing for the multi-modal authentication of occupants. The eye-tracking system monitors a driver’s irises, eyelids and gaze – should the driver become distracted or fatigued, AI safely takes control of the vehicle.

With the use of 8 radar systems, 6 Lidar sensors, and half a dozen external cameras, the SC1 Vision Concept is fully equipped for autonomous motoring in the future. It will store information on cityscape and points of interest which are displayed in augmented reality.

Both driver and passenger can immerse themselves in comfort with an all-new surround audio system with dedicated sound environments for each of them. Karma says it will soon offer audio capabilities similar to the SC1 Vision Concept’s system through the company’s guided customization program.

New definition of luxury and style

“The SC1 Vision Concept draws its inspiration from Karma’s pioneering spirit,” said Andreas Thurner, Karma’s VP of Global Design and Architecture. “It is thought-provoking — it conjures a new definition of luxury and style with distinct Karma DNA.”

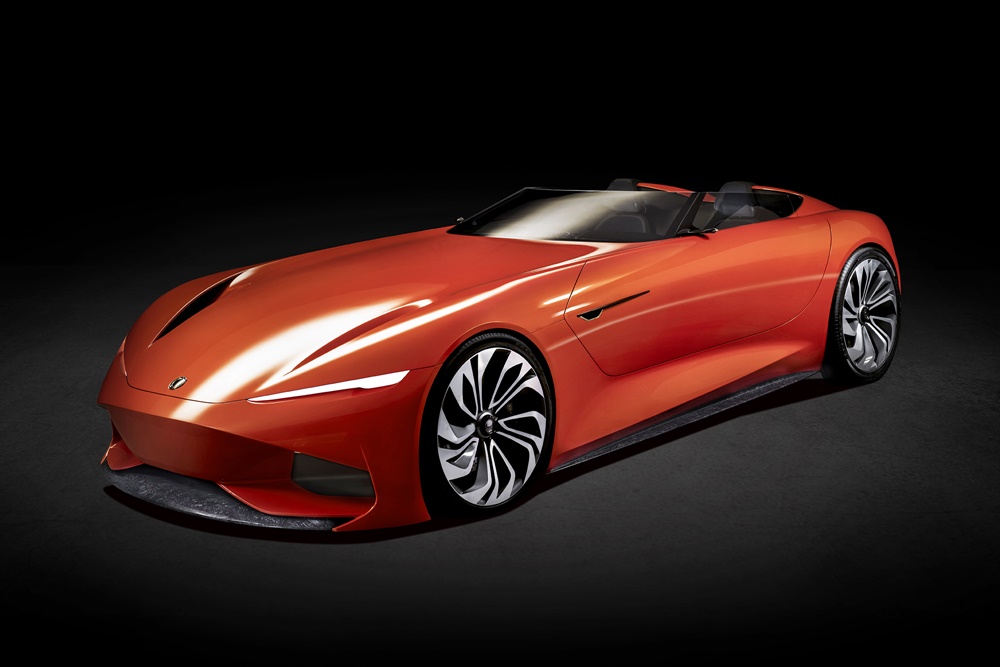

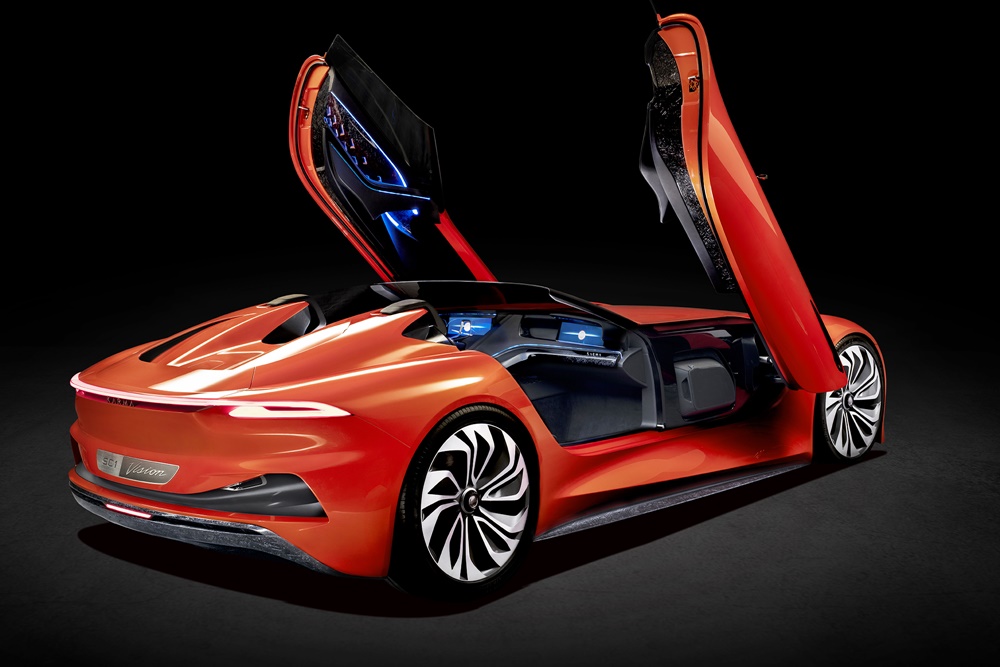

The SC1 Vision Concept features a one-off fluorescent orange paint scheme with flakes of violet mica capturing stunning sunset colours, juxtaposed by a darker palleted interior fading from black to deep indigo. A bold body design is reminiscent of an H-1 racing aircraft of the 1930s, with impressive length stretching from the car’s front axle to windscreen.

Striking patented articulating hinge doors open in a winged motion, gently rising up and forward, rotating around front wheels. The SC1 Vision Concept’s interior prioritizes simplicity and ease of use, eliminating excess to reveal a stratified design with a multi-dimensional in-cabin experience. The car’s battery is housed in a centre tunnel cascading down from dashboard into seats, before gliding upward to the decklid.