At the very beginning of 2022, the Dakar Rally will be on again in Saudi Arabia. Among the participating teams will be Audi Sport which was a pioneer in the World Rally Championship with the quattro all-wheel drive in a rallycar. This time, it wants to be the first car manufacturer to use an electrified drivetrain to compete for overall victory against conventionally-powered competitors in the world’s toughest rally.

“The quattro was a game-changer for the World Rally Championship. Audi was the first brand to win the Le Mans 24 Hours with an electrified drivetrain. Now, we want to usher in a new era at the Dakar Rally, while testing and further developing our e-tron technology under extreme conditions,” said Julius Seebach, MD of Audi Sport which is responsible for motorsport at Audi.

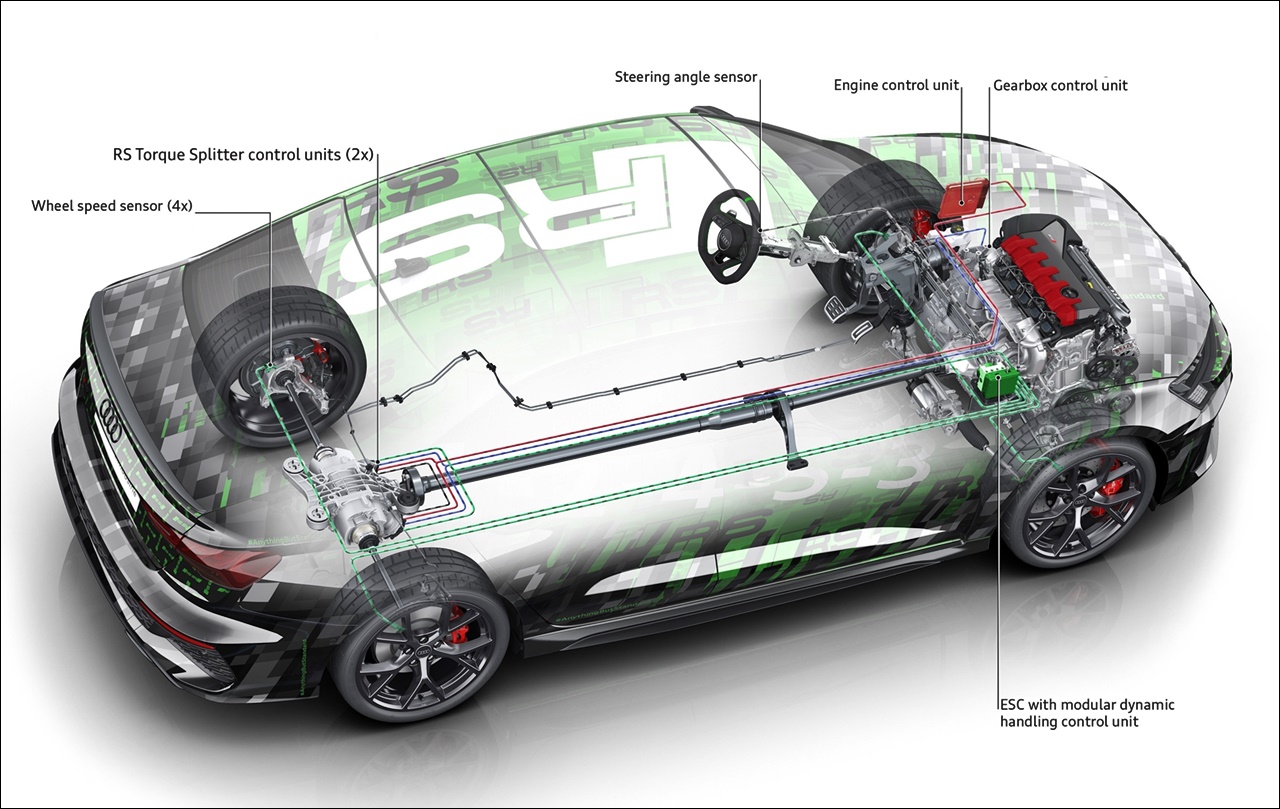

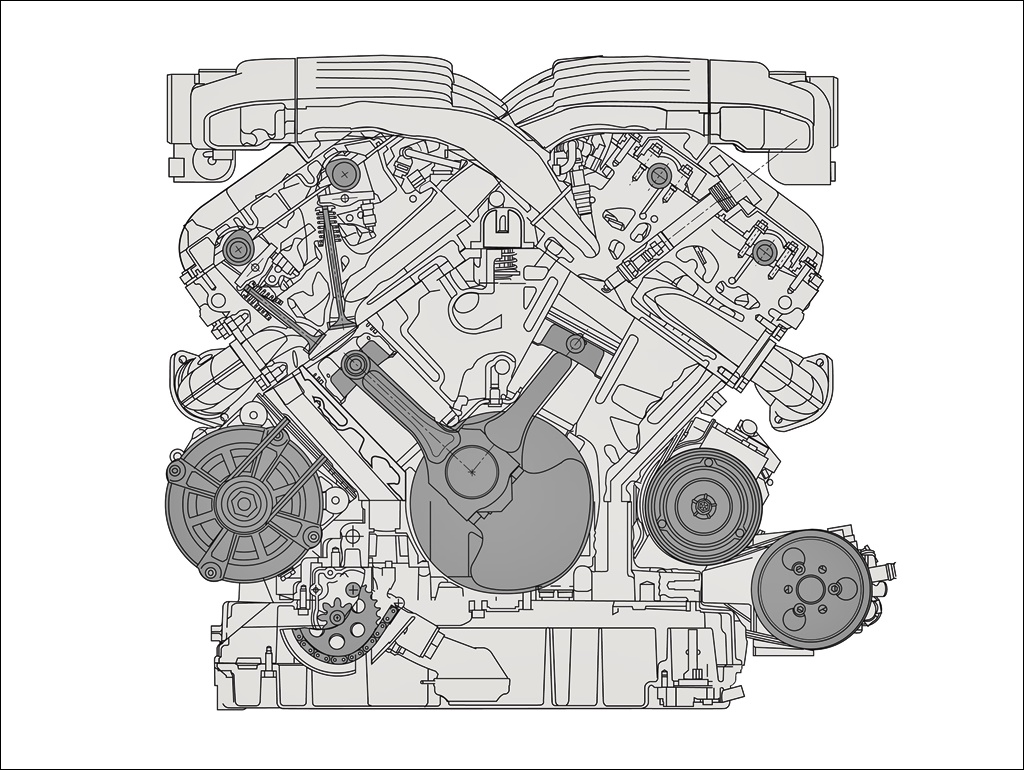

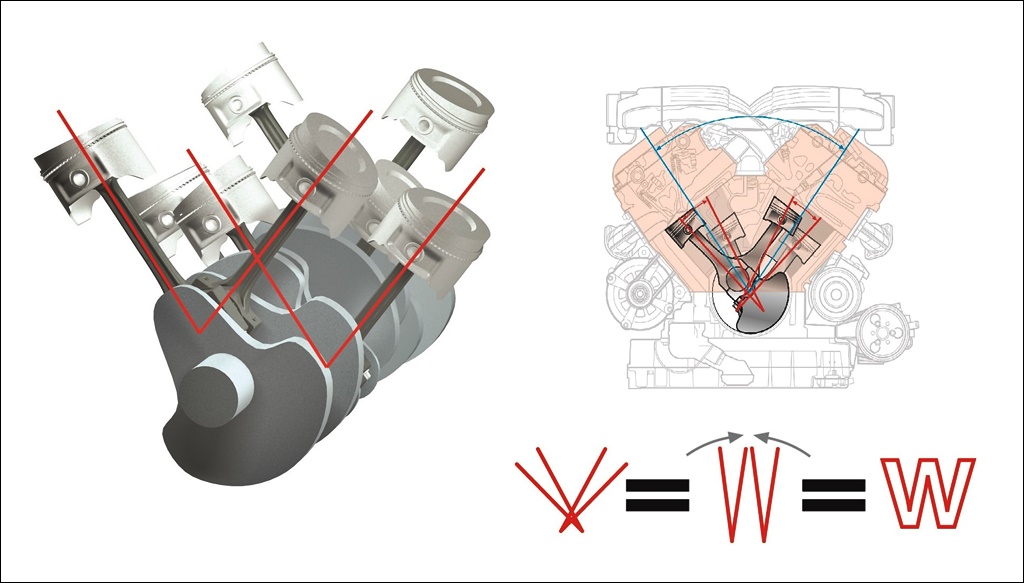

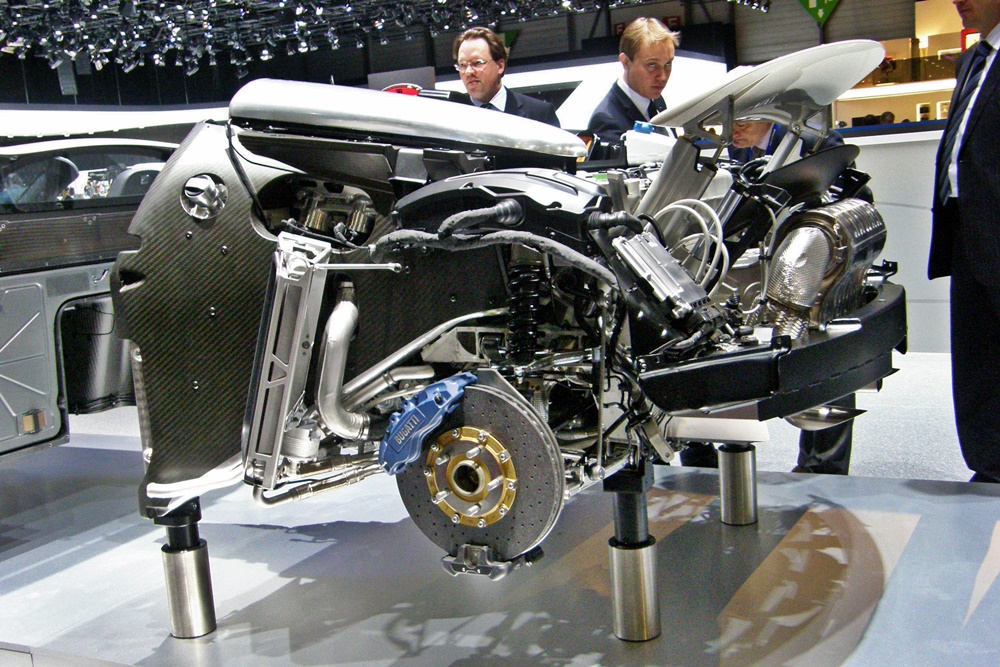

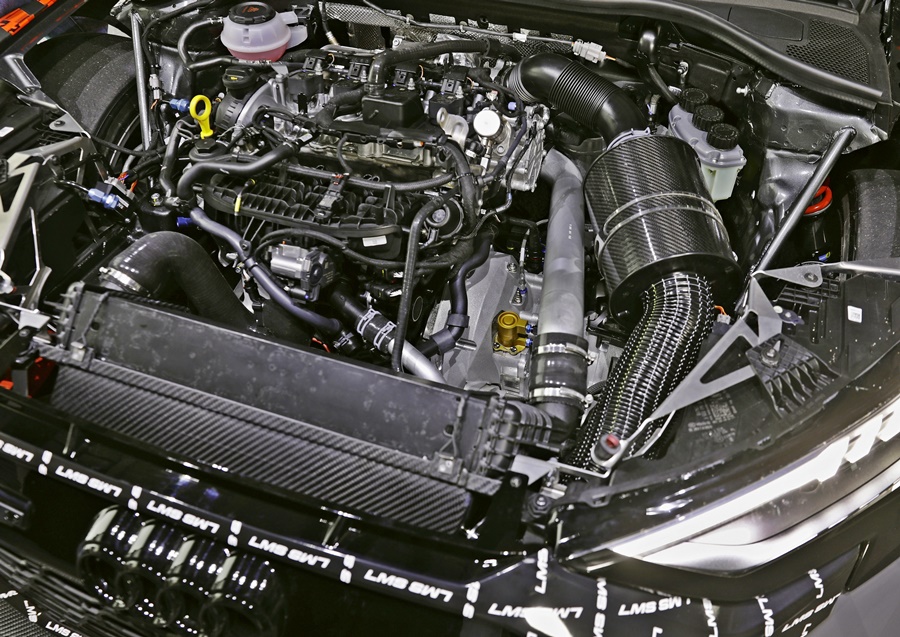

Testing and preparation are underway with the new RS Q e-tron which has an all-electric drivetrain. The front and rear axles are both fitted with a motor-generator unit (MGU) from the current Audi e-tron FE07 Formula E car which has been developed by Audi Sport for the 2021 season. Only minor modifications had to be made to use the MGU in the Dakar Rally.

The characteristics of the Dakar Rally present the engineers with special challenges. The marathon event lasts 2 weeks and the daily stages are up to 800 kms in length. “That’s a very long distance,” said Andreas Roos who is responsible for the Dakar project at Audi Sport. “What we are trying to do has never been done before. This is the ultimate challenge for an electric drivetrain.”

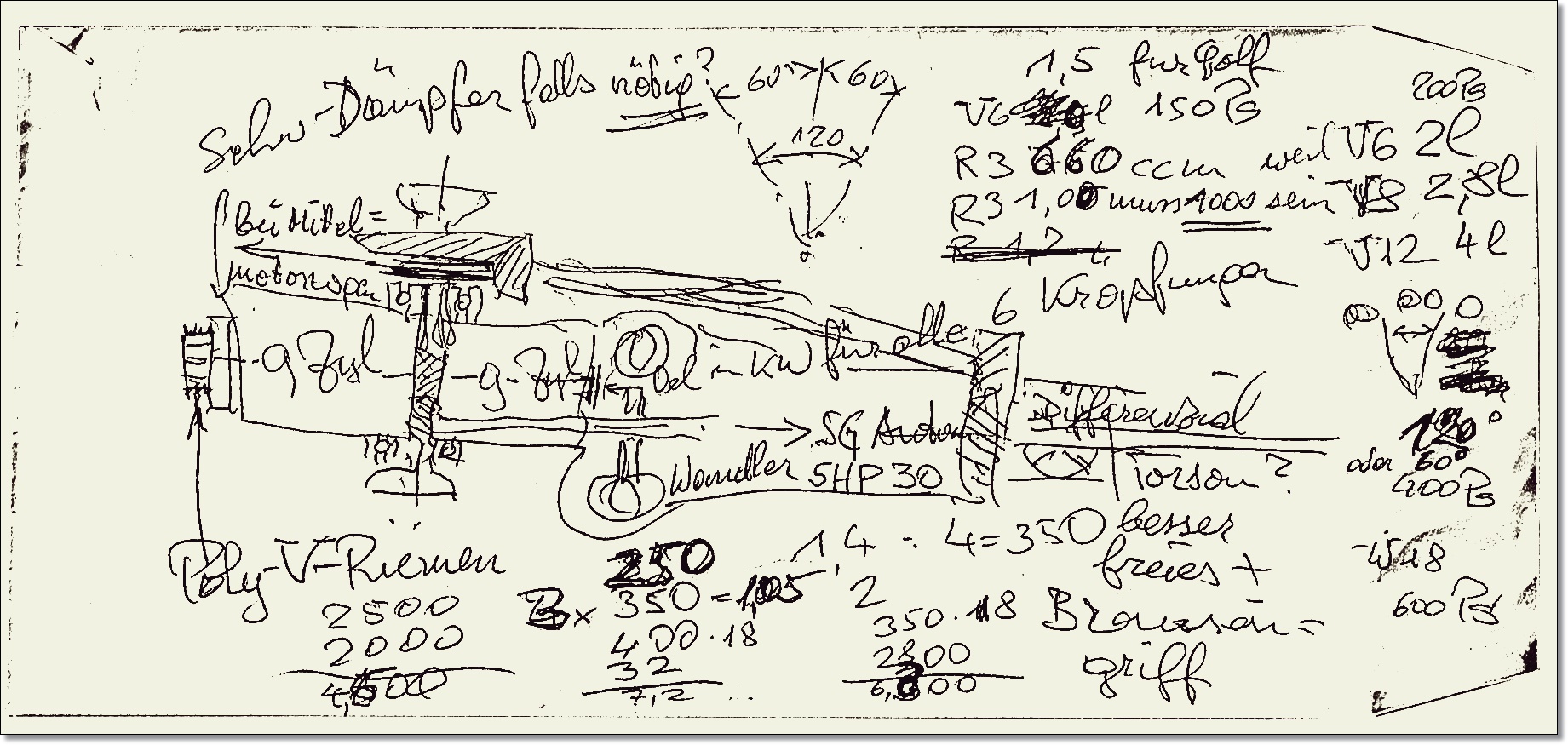

Because there are no charging opportunities in the desert, Audi has chosen an innovative charging concept. On board of the car is the highly efficient TFSI engine from the DTM. It is part of an energy-converter that charges the high-voltage battery while driving. Since the combustion engine is operated in the particularly efficient range of between 4,500 and 6,000 rpm, the specific consumption is well below 200 grams per kWh.

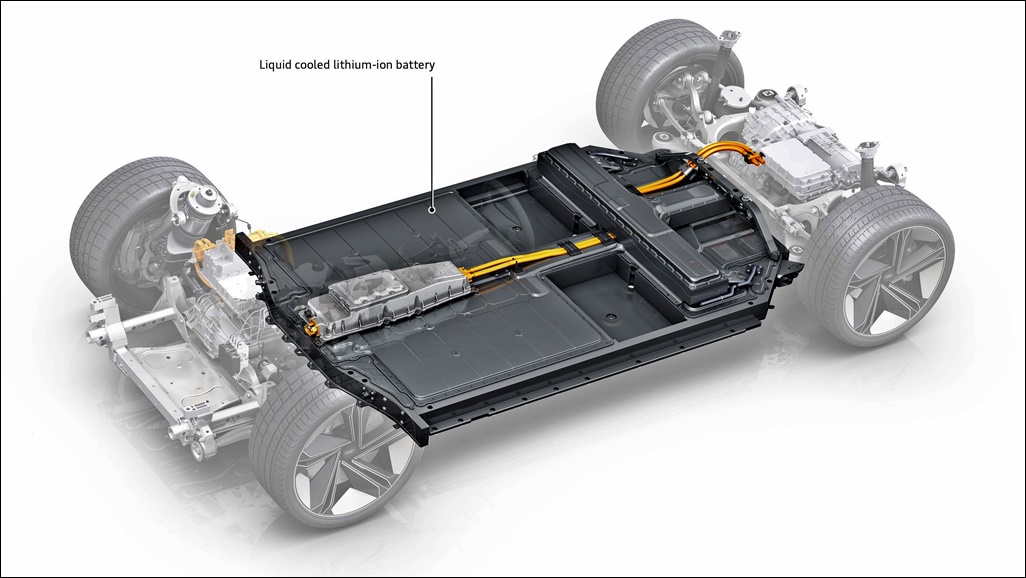

A third MGU, of identical design, is part of the energy converter and serves to recharge the high-voltage battery while driving. In addition, energy is recuperated during braking. The battery weighs about 370 kgs and has a capacity of around 50 kWh.

The maximum system power of the e-drivetrain is 500 kW. How much of this may be used during the Dakar Rally is still being finalized by the organizers. The electric drivetrain offers many advantages. The electric motors can be controlled extremely precisely and can thus ensure good drivability. In addition, braking energy can be recovered.

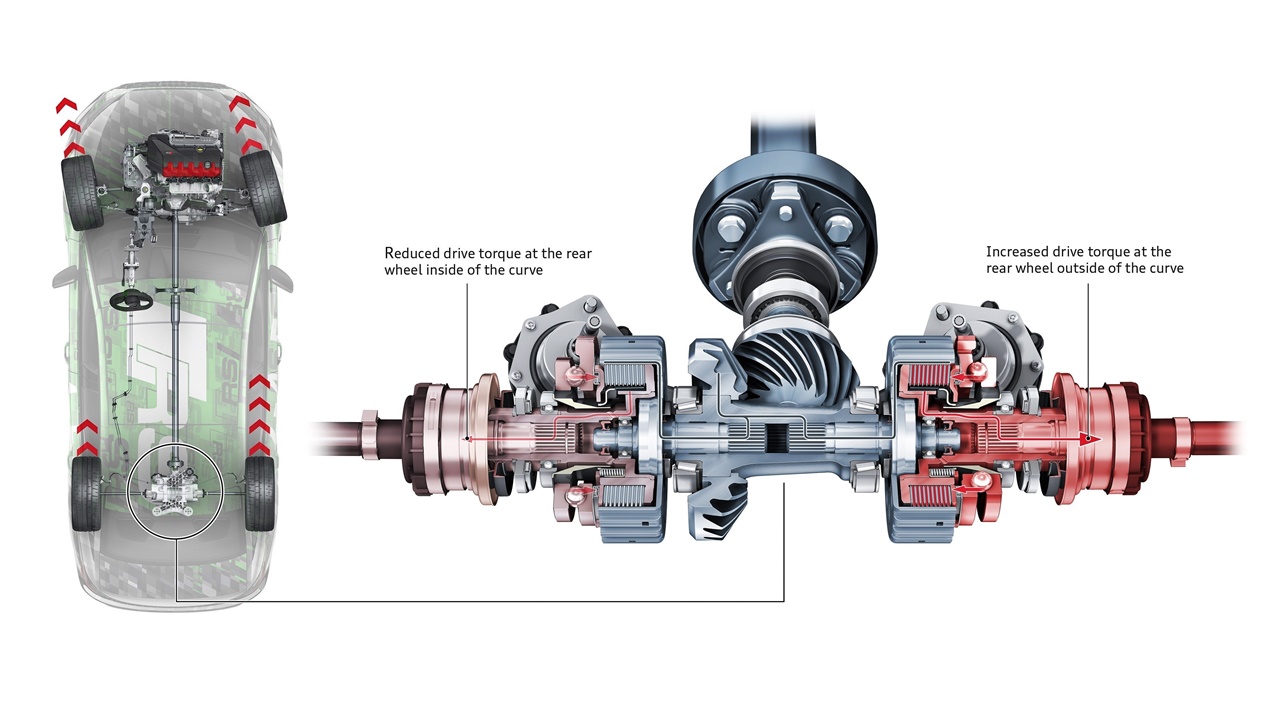

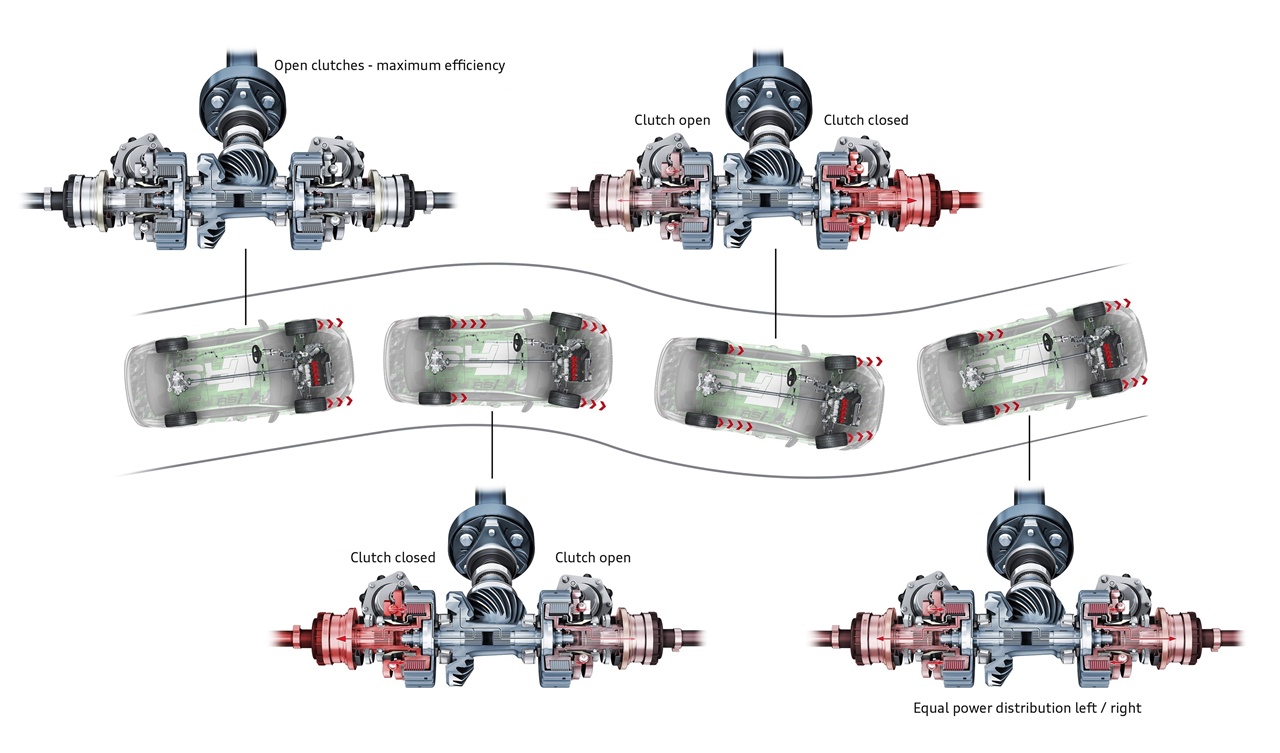

The RS Q e-tron only needs one forward gear. The front and rear axles are not mechanically connected, as is also common in electric vehicles. The software developed by Audi takes over the torque distribution between the axles and thus creates a virtual and freely configurable centre differential, which has the positive side effect of being able to save the weight and space that would have been required by propshafts and a mechanical differential.

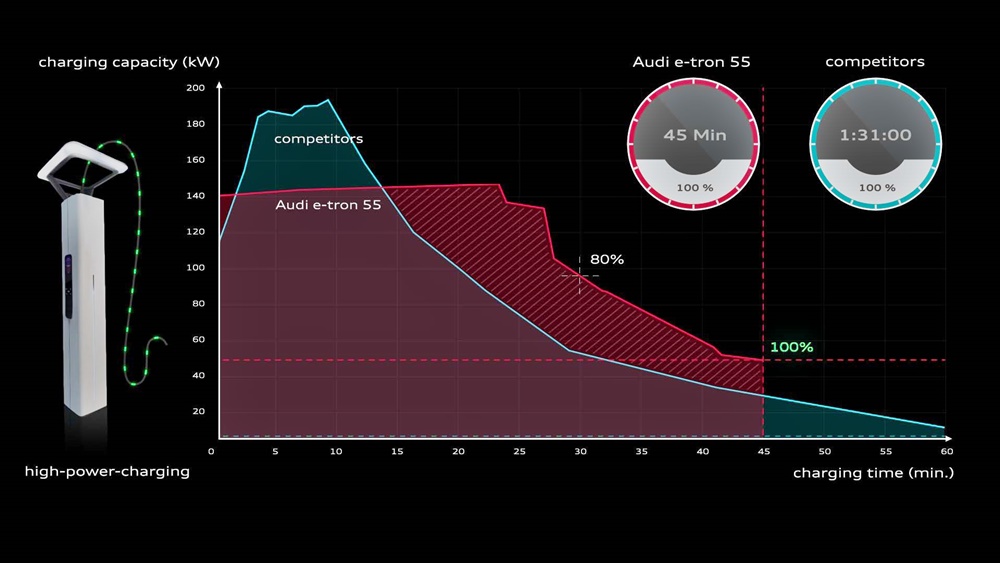

“As engineers, we basically see development potential in every component. But in terms of the drivetrain system, we have already achieved a system efficiency of over 97% in Formula E. There’s not much more room for improvement,” revealed Stefan Dreyer, Head of Development at Audi Sport for motorsport projects.

“The situation is quite different with the battery and energy management. This is where the greatest development potential lies in electromobility in general. What we learn from the extremely challenging Dakar project will flow into future production models. As always, we are also working closely with our colleagues from road car development on this project,” he added.

The Dakar Rally entry is being run in conjunction with Q Motorsport. “Audi has always chosen new and bold paths in racing, but I think this is one of the most complex cars that I have ever seen,” said team principal Sven Quandt. “The electric drivetrain means that a lot of different systems have to communicate with each other. Besides reliability, which is paramount in the Dakar Rally, that’s our biggest challenge in the coming months.”

Quandt compares Audi’s Dakar project to the first moon landing. “Back then, the engineers didn’t really know what was coming. It’s similar with us. If we finish the first Dakar event, that’s already a success!” he said.

The prototype of the RS Q e-tron had its first roll-out in the plant only at the beginning of this month. An intensive test program and the first test entries at cross-country rallies are on the agenda from now until the end of the year. “This project’s schedule is extremely packed and challenging,” said Roos. “Less than 12 months have passed since the project officially started. We had to begin the development while the regulations for alternatively-powered vehicles had not even been finalized yet. And all of the development took place during the coronavirus pandemic. You mustn’t underestimate that either. What the team has achieved so far is unique. The roll-out was a very special moment for everyone.”

Audi to compete in Dakar Rally 2022, return to WEC, and leave Formula E after 2021