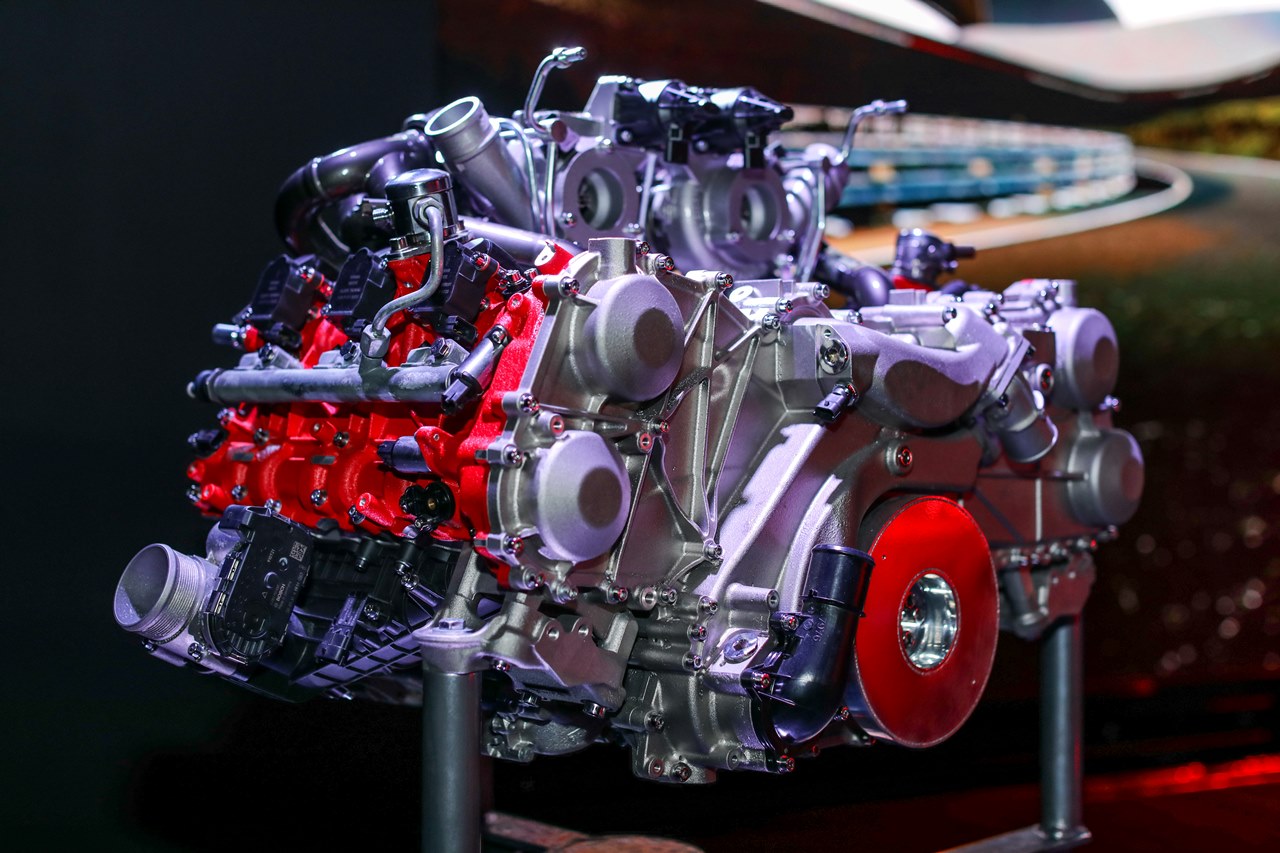

Bugatti will build only 10 units of the Centodieci, the most exclusive model from the French brand. And even though it is a small number, the cost and time for engineering, development and testing has been no less than for any other model. In fact, if one were to use the 10-unit production run as a basis, it is probably the most expensive model in development cost.

Over the course of many months, Bugatti test drivers and engineers have carried out all types of testing on various roads and tracks and in various conditions to collect technical data on performance and reliability. To date, the production-based prototype of the Centodieci has completed over 50,000 test kilometres in total following final endurance testing.

The white prototype has been run virtually non-stop with 3 drivers taking turns. It may sound like a fun job being able to drive fast for long periods (and no worries about speed-traps!), but it is a serious one. Endurance testing requires drivers to have a high level of technical knowledge, maximum concentration, and sensitivity. During driving, they must examine all functions of the hypercar, registering and logging every minor issue. They drive day and night on different track profiles and across every speed range, from stop-and-go pace to top speed.

Even after hours going round and round the same high-speed track at Nardo in Italy, they must be able to pick up the slightest of unusual noises, movements, and irregularities. Everything is inspected one final time: driving on different surfaces – both wet and dry – testing every little steering movement, braking, acceleration, cornering load, and functionality of the driver assistance systems.

“With its high-speed circuit and handling course, the Nardo test centre provides the ideal conditions for intensive endurance tests,” said Steffen Leicht, the man responsible for endurance testing at Bugatti. The 12.6-km circular track with a diameter of 4 kms is considered the fastest automotive circuit in the world – ideal for the 380 km/h Centodieci.

It also has a 6.2-km handling course on the inner section that enables drivers to check performance and dynamic behaviour at the highest load levels and with longitudinal and transverse dynamics. In total, the facility has 70 kms of roads with different surfaces, enabling extensive testing and inspection of all vehicle components.

During endurance testing, the Centodieci covered up to 1,200 kms each day, interrupted only by technical checks, refuelling, and driver changes. Throughout the entire time, Bugatti’s engineers analyze the engine and vehicle data and make adjustments where necessary. “We assess every element on the vehicle one last time, paying particular attention to functionality and durability before the first Centodieci cars go into production,” explained Carl Heilenkotter, project manager responsible for one-off and few-off projects at Bugatti.

“All components must interact perfectly with one another and be capable of withstanding any kind of overloading. They must also harmonize in a stable and safe manner even when subjected to the most severe handling situations,” he explained.

The testing that is carried out is no different from what Bugatti has been doing for more than 100 years to ensure the highest quality for its cars. However, new technologies have enabled the engineers to carry out testing in more sophisticated ways today and to go well beyond the legal and expected requirements.

“The Centodieci is deliberately driven to its limits in order to guarantee reliable handling at the highest level, even in extreme situations. Even though most cars never enter this range, it is nonetheless tested. This is the philosophy of the brand and that is why we put such a huge amount of effort into all this testing. Bugatti is committed to the highest quality standards, durability, and customer satisfaction,” said Heilenkotter. “The endurance tests in Nardo represent the final act of the extensive trials.”

As soon as the final assessment has been completed, the first of the highly exclusive vehicles – each with a starting price of 8 million euros (about RM37.17 million) – can go into production. All the 10 hypercars – which have 8-litre 16-cylinder 1,600 ps engines – will be completed in the coming months and their owners will receive them later this year.

FEATURE – The German engine that was born on a Japanese bullet-train