‘Range anxiety’ was something which concerned many who were considering a battery electric vehicle (BEV). The earlier models could go just a 100+ kms on a fully charged battery pack but the distance gradually increased as battery technology advanced. As battery packs were made more energy-dense to store more electricity, the vehicle could go further and further before recharging was needed. Today, the average is around 350 kms but just as with the consumption of fuel by combustion engines, range is affected by driving conditions and driving style.

But range anxiety is now less concerning not only as cruising distances increase but the network of recharging stations is also growing. So it is possible to ‘refill’ along the way on a long journey and now, it is more a matter of how long that takes – and manufacturers are also reducing the time.

Battery technology has come a long way in the past decade and if we take the Nissan LEAF as an example, the range with the first generation launched in 2010 was under 200 kms; today, the latest generation is claimed to be able to go up to 385 kms.

Breaking through technological barriers

In future, the distance will be even greater and Mercedes-Benz has proven that it is possible to go up to 1,000 kms on a single charge. This was achieved with the VISION EQXX technology demonstrator which the company is using to test technologies under development. This software-defined research prototype is part of a far-reaching technology programme that combines the latest digital technology with the brand’s pioneering spirit, the agility of a start-up and the speed of Formula 1. The mission in developing the VISION EQXX was to break through technological barriers across the board.

“The VISION EQXX is the result of a comprehensive programme that provides a blueprint for the future of automotive engineering. Many of the innovative developments are already being integrated into production, some of them in the next generation of modular architecture for compact and midsize Mercedes‑Benz vehicles. And the journey continues. With the VISION EQXX, we will keep testing the limits of what’s possible,” said Markus Schafer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer responsible for Development and Purchasing.

From Germany to the south of France

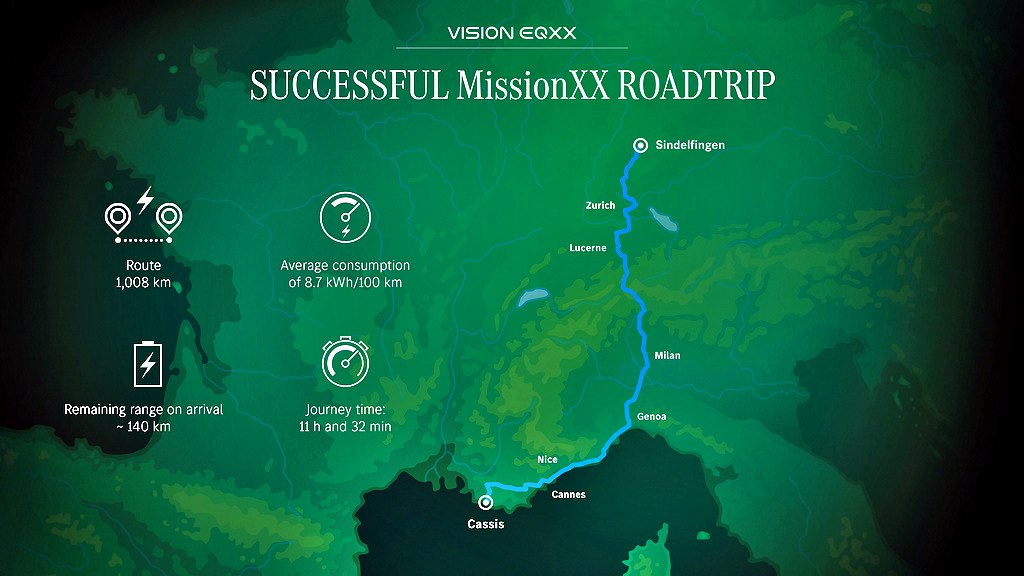

To show what is electrically ‘feasible’, the research vehicle completed a 1-day road trip across several European borders: from Germany across the Swiss Alps to Switzerland, on to Italy, past Milan and finally to its destination, the port town of Cassis in the south of France. The journey started in cold and rainy conditions and proceeded at regular road speeds, including prolonged fast-lane cruising at up to 140 km/h on the German autobahn and near the speed limits elsewhere.

The route profile set and the weather conditions presented the VISION EQXX with a wide variety of challenges. Different various sections of the route helped document the effect of the many efficiency measures. These measures include tyres specially developed by Bridgestone with extremely low rolling-resistance.

Throughout the journey of 11 hours and 32 minutes, it was not recharged and covered 1,008 kms in everyday traffic – with the battery’s state of charge on arrival shown as being around 15%. That was estimated to be good for another 140 kms or so, and the average consumption was a record-breaking low of 8.7 kWh per 100 kms.

Power from sunshine

However, Mercedes-Benz reveals that although it did not receive conventional recharging, it still received electricity from an external source – the sun. On its roof are 117 solar cells to collect sunshine which is converted to electricity and fed to the 12V battery. This battery does not power the electric motors but supplies power to auxiliary areas such as the navigation system. This this removes the demand from the high-voltage battery pack. The solar panel feature is said to increase the range by more than 2%, which adds up to 25 kms on a journey of over 1,000 kms.

Like most other BEVs, the VISION EQXX also uses recuperation – the recovery of braking energy – to provide some energy to the battery pack while on the move. The recuperation effect occurs on any type of gradient and during every braking manoeuvre.

The VISION EQXX was driven in real-life conditions and to have independent proof, the charging socket was sealed, and the car accompanied by a representative from TUV Sud, the independent German certification body.

Technological advancements accelerating

In the early era of the PC (personal computer) in the 1980s, the processing power doubled every two years, but this has accelerated as time passed. It might be the same for battery and EV technology which is continuously advancing each year so from the 500 kms possible in some models today, the increases might be greater and who knows, by the next decade, the 1000-km range which is amazing today might be possible in BEVs for sale to the public.

The most efficient Mercedes-Benz ever built – the Vision EQXX