The latest Isuzu D-MAX is clearly a winner for Isuzu Malaysia, having set a national sales record last month with 1,233 units delivered around the country. That was the company’s highest ever monthly sales since being established in 2005. The new figure eclipses the previous record of 885 units recorded in December 2014 following the introduction of the D-MAX 3-litre V-Cross.

Although the industry has been facing difficulties in getting enough vehicle stocks, Isuzu Malaysia was fortunate to get a large shipment of vehicles which enabled it to address the backlog of orders that began almost from the time the third generation model was launched.

According to the Chief Operating Officer of Isuzu Malaysia, Kenkichi Sogo, the boost in deliveries allowed the company to relieve some of the customers’ waiting time for their new vehicles. “Our customers depend on Isuzu vehicles to serve them faithfully so, as a customer-centric brand, our priority was to hasten supply to meet the increased demand for this highly-popular and versatile pick-up truck,” he said. “I wish to thank our customers who have eagerly and patiently waited for their brand new Isuzu D-Max. We hope to continue ramping up supplies over the coming months to further reduce the waitlist for our vehicles.”

The increased supply that was achieved through additional allocation from the factory meant that the top variant delivered in March was of the 1.9-litre Premium Auto variant, with close to 350 units. The Premium Auto variant offers stylish design, excellent driving performance, premium interior features and the lowest roadtax in its segment, which is why it is the popular choice.

Demand for the flagship X-Terrain variant was also met with an increase of 163 deliveries. However, this version is one of the most popular globally and so supplies have been limited. It has advanced safety and comfort features which can be compared to passenger cars, so it is ideal for personal use as well as workhose duties when needed.

The strong performance in March would have pleased the company’s new CEO, Shunsuke Okazoe, who emphasises the need to prioritize customer satisfaction through improved sales and aftersales efforts. Mr. Okazoe, who has been involved in the Isuzu business for the past 26 years, has served in various countries such as Japan, America, India and Thailand. He aims to strengthen the Isuzu network and build greater customer satisfaction in Malaysia.

“While Isuzu Malaysia is still a relatively young company, our customer base has grown significantly in the past 17 years. Isuzu’s strong brand reputation, dependable product line-up and a strong support network has helped us create a very strong platform for growth. Our immediate aim therefore will be to enhance our support system in tandem with the growing population of Isuzu customers,” he said.

Isuzu Malaysia currently has a network of 54 outlets positioned strategically in populated centres around the country. It will soon embark on a network enhancement exercise with its authorised dealers to ensure customers enjoy a more comprehensive experience in a conducive and comfortable environment.

Switching to the trucking lifestyle with the Isuzu D-MAX X-Terrain

In the mid-1960s, when the Malaysian government started the auto industry with a call to manufacturers to assemble vehicles locally, the first ‘auto city’ began to form in the Klang Valley. Vehicle assembly plants were set up in the newly created Shah Alam industrial area of Selangor and related businesses also built factories nearby to supply them parts.

As the industry grew, other areas of the country also saw auto-related factories and businesses being developed. These were in the Tampoi area of Johor and also in Pekan, Pahang, where manufacturers like General Motors, Honda, Mitsubishi Motors, Fiat and Tata had their vehicles assembled.

When the National Car project started in the early 1980s, the Proton factory was situated in Shah Alam, mainly because many suppliers were also in the Klang Valley which also has the largest concentration of new vehicle sales. Perodua, however, chose an area in northern Selangor near Rawang for its manufacturing complex but with the North-South Highway, it had easy connections to the Shah Alam area for suppliers to deliver parts.

By the late 1990s, the auto industry was booming and Proton was seeing rapid growth in volumes that it needed a second factory. Tanjong Malim in Perak was chosen and though far from the Klang Valley, the distance was no longer an issue with the highway connection that also went to Port Klang. DRB-HICOM even made plans to create a ‘Proton City’ which would be an ‘auto city’ like Toyota City in Japan and Detroit in the USA.

However, the late 1990s saw the Asian Financial Crisis seriously affecting the country’s economy and projects like Proton City could not proceed as planned. It had been planned that suppliers would set up factories in the area to support the Proton factory which was designed to produce up to 500,000 vehicles. However, response was poor and with the severe downturn, the idea of Proton City could not take off although Proton began operations at its factory to make a new generation of models.

20 years later, the Proton City idea is restarting although this time, the concept has been updated to take into account changes in the auto industry. Rather than being just a ‘Proton City’, DRB-HICOM will develop the Tanjong Malim area into an Automotive Hi-Tech Valley (AHTV) with the aim of becoming an industry hub for the ASEAN region.

Besides supporting Proton, the AHTV is expected to attract businesses which are involved in new technologies and systems relevant to the global automotive industry. These would include electrification, Artificial Intelligence, autonomous technologies and advanced connectivity.

AHTV will be developed with an integrated ecosystem that will be a catalyst to revitalize domestic automotive sector in line with the direction of the National Automotive Policy 2020. Its aim is to bring Malaysia’s automotive industry to be on par, if not more advanced, than those in neighboring countries.

Perhaps it could help make Malaysia once again the best place in ASEAN to manufacture motor vehicles, which was the case in the 1970s. Back then, this country had the best infrastructure, a growing economy, well educated workforce and a level playing field which was attractive to investors.

An early supporter of the AHTV is the Geely Holding Group, which is also DRB-HICOM’s partner in Proton. The Chinese company has signed an MOU (Memorandum of Understanding) to jointly develop AHTV and collaborate to identify vendors and investors to the hub. The involvement of Geely, which has rapidly become a diverse global automotive group, will bring their technological strength in the automotive ecosystem as a boost for AHTV. This can be an impetus for auto and component manufacturers, especially from China, to invest in local production facilities, to create new business and export opportunities. Essentially, AHTV has the potential to become a gateway to ASEAN and other markets for companies that make it as their base. To date, there are already 17 vendors with facilities within the area.

DRB-HICOM has also signed another MoU with the Perak state government to jointly identify suitable additional land in the area for AHTV development. The current area surrounding the Proton factory measures 4,000 acres, with most already occupied by University Pendidikan Sultan Idris, factories of existing vendors, commercial premises and residential properties.

To boost the automotive talent pool in Malaysia, AHTV will establish a research university. This will create an educational framework to nurture a new generation of engineers for the automotive industry in areas of Engineering, IT, Design, Artificial Intelligence, Mobility Solutions & Software Development. This will strengthen local R&D capabilities and ensure competitiveness of local original equipment manufacturers.

The scale of the AHTV will see some 370,000 job opportunities being created in the area, with more than 160,000 opportunities during the first phase of development.

Proton constructing additional stamping facility at Tanjung Malim factory

Every major global carmaker, especially those in Europe, have announced electrification plans that will see their brand going fully electric or having a mix of hybrid electric and battery electric (BEV) models. This is an industry-wide move to address climate change and environmental issues, and the auto industry is responding by switching to vehicles with electrified powertrains that generate very low or zero emissions. There is an urgency so the end of this decade is set as the target for completing the changes.

Maserati will be the first among the Italian luxury car brands to produce full-electric models, with the first one to be launched in 2023 and an aim to be the first to complete its electric line-up by 2025. All the fully electric models will be developed, engineered and entirely produced in Italy and form the new Folgore range (‘folgore‘ is Italian for ‘lightning’).

The first model will be the Gran Turismo Folgore, a coupe which the company says will have ‘cutting-edge technical solutions, superb performance, comfort and elegance’. Technical details are not revealed yet although it is believed that the powertrain will have 3 motors and a total output of up to 1,200 ps.

Maserati has given assurance that while exhaust emissions will fall to zero, one iconic element of the cars with the Trident will still be present: the distinctive growl. Of course, the equivalent for electric motors would usually be a high-pitched whine so it will be interesting to see how the engineers incorporate that familiar adrenalin-pulsing roar.

Following the Gran Turismo Folgore will be the Grecale Folgore, which is a fully electric variant of the second Maserati SUV model. It will have a 105-kW/h battery pack using 400V technology and two motors which will generate a total of up to 800 Nm of torque. This is also scheduled for launch towards the end of 2023 so it might go on sale only in 2024.

For 2025 or 2026, the next generation of the Quattroporte sedan and Levante SUV will make their debut and are likely to be only available with electric powertrains. By then, as mentioned earlier, Maserati will have every model in its range electrified. The other target for the end of the decade would be when it no longer has a combustion engine powertrain in any of its models.

As part of its journey onwards to electrification, Maserati will also make its debut in the next season of Formula E (season 9) next year. It will be the first Italian brand to enter Formula E and its partner will be the ROKiT Venturi Racing team, already successfully running in the series. Season 9 will see a new generation of racing cars that have a range of innovations in terms of design, production and technology.

Maserati starts electrification journey with new Ghibli Hybrid

It wasn’t surprising when Nissan was the first Japanese carmaker to become involved in Formula E which is now a world championship. The carmaker became dominant in the electric vehicle (EV) segment after introducing the world’s first mass-produced EV, the LEAF in 2010, so it was natural for it to participate in the all-electric series.

That was back in 2018 when the company partnered the e.dams team and started off in the fifth season of the series. It drew on its experience developing EVs to develop a new powertrain package for its Formula E car, including a new electric motor, inverter, gearbox and software.

Following its entry in the fifth season, the team has been among the regulars each season and in March 2021, Nissan confirmed further commitment to Formula E. Now, the company is going on step further by acquiring the French-based e.dams team which will finish off this season with the Gen2 car and then start the next season with the new Gen3 racing car. Nissan will be present until the end of Season 12 (2025/26).

“It’s taken years of planning and months of intense preparation, but we’re now ready to hit the track for our Formula E race debut,” said Michael Carcamo, Nissan’s Global Motorsports Director. “We’ve drawn on our experience as a global leader in electric vehicles for the road to help develop our Formula E powertrain – and what we now learn on the track will go back the other way, benefiting Nissan’s electric-car customers.”

Nissan’s participation in Formula E supports the company’s long-term commitment to electrification and sustainability laid out in Nissan’s ‘Ambition 2030’ plan. “These are exciting times for all of us at Nissan, our fans and customers everywhere,” said Ashwani Gupta, Nissan’s Chief Operating Officer. “We have been on the grid for over 85 years, and our desire to win continuously accelerates us forward. We learn as we race, and the relentless pace of technological progression that drives the Formula E championship will provide us with many opportunities to inform and develop even better cars for customers.

As part of its goal to achieve carbon neutrality across its operations and the life cycle of its products by 2050, Nissan intends to electrify all its new vehicles by the early 2030s in key markets. The Japanese carmaker aims to bring its expertise in transferring knowledge and technology between the Formula E racetrack and road for better electric vehicles for customers.

“I am delighted that Nissan is taking over e.dams and today we are thinking of Jean-Paul Driot who, together with Nissan, had the vision for the team and helped to develop our partnership,” said Tommaso Volpe, who will become the Managing Director of the Nissan Formula E team. “Since his passing in 2019, Olivier and Gregory Driot took over and made sure the legacy of their father’s success would continue. It has been a pleasure working together and I would like to thank them for their commitment and support.

“We are very proud to hand over the e.dams team to such a committed and innovative company as Nissan. We’ve had several open discussions in recent months with Nissan and we decided that it was the right time for them to take the reins and continue the legacy of our family and secure the long-term future of the employees,” said the Driot brothers.

Nissan e.dams team ready for first round of Formula E Season 8 in Saudi Arabia

As with the City Sedan, Honda Malaysia has now added another variant of the City Hatchback with the Honda SENSING driver-assistance package for those who want more advanced safety systems. The new City Hatchback V-SENSING variant is similar to the City Hatchback 1.5V and is priced from RM91,708.51 (excluding insurance and sales tax), which is around RM3,852 more than the 1.5V without Honda SENSING.

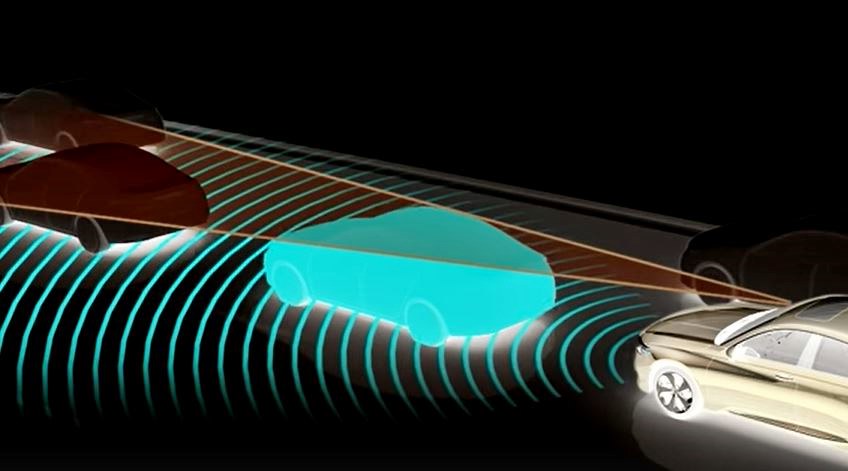

While Honda has provided various types of active safety systems over the years such as ABS, Vehicle Stability Assist and Traction Control, these have been independent in their functions. With Honda SENSING, which was first introduced in 2015 in Japan and 2017 in Malaysia (with the 5th generation CR-V), the active systems function in a collaborative manner and expand the capabilities of recognizing as well as reacting to potential accident situations.

Such unified systems use either a radar or a camera, or both, to scan the road ahead for other vehicles and road-users as well as road markings. More expensive models usually have the radar as well but for the City Hatchback (and Sedan), Honda uses only a camera, probably to reduce the cost. However, compared to the earlier Honda SENSING system, the camera (mounted in the space above the rearview mirror) in the latest one has a wider view and improved imaging capabilities in all lighting conditions. The imagery captured by the camera is constantly analysed and also picks up lane markings on the road as well as the edge of the road.

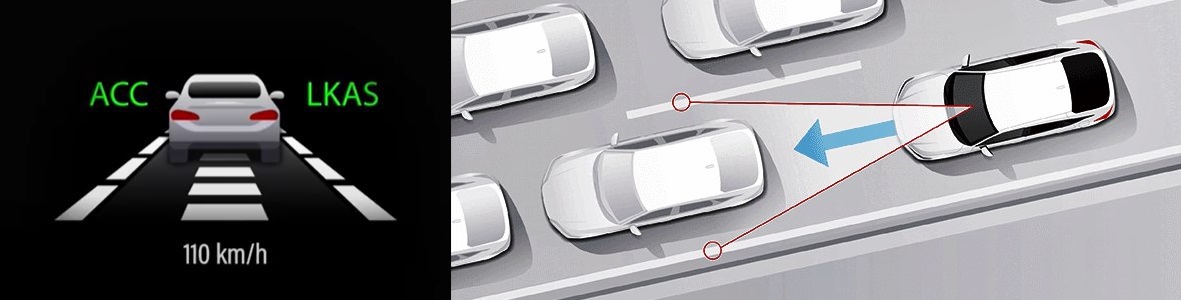

Compared to the original Honda SENSING system first introduced in Malaysia, today’s system has increased features and consists of:

ACC is a more advanced type of cruise control where the car can run in semi-autonomous mode. The driver still needs to pay attention and steer but once the cruising speed is set, there is no need for the driver to use the brakes to slow down if there is a vehicle ahead. The system will do it automatically to maintain a safe distance, returning to the set speed when there is no vehicle ahead. This will not only make driving easier in heavy traffic but also help to reduce fatigue on long journeys, improving safety.

CMBS and FCW are related systems, both functioning to prevent a collision with a vehicle ahead or hitting other road-users. FCW will warn the driver by sound and by warning lights if there is a risk of a collision. If the driver does not act to prevent this from happening – ie slowing down or braking – CMBS then activates and the brakes will be applied automatically. While the automatic emergency braking may or may not prevent a collision (depending on road conditions and speed), the earlier deceleration could reduce the damage of the impact if it occurs.

Incidentally, when CMBS occurs, the rear brake lights automatically flash and the hazard warning lights will also come on. This is to alert drivers in vehicles behind of the sudden braking so they won’t also collide… not all cars may have systems like Honda SENSING.

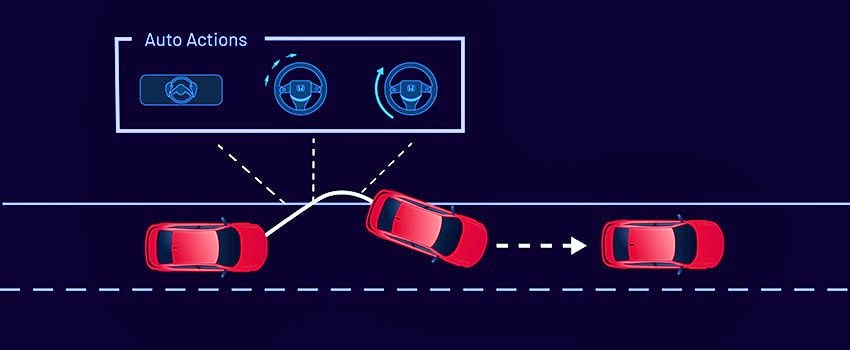

LDW, LKAS and RDM also related and their main function is to keep the car within its lane. These systems were developed as studies have found that many accidents have occurred due to the car wandering out of its lane without the driver being aware (usually due to lack of attention or drowsiness). The systems will not activate if a turn signal is in use, signifying that the car’s movement out of its lane is deliberately done.

The process starts with LDW which relies on the camera imagery to recognise lane markings. This may not be 100% perfect since the markings may not be present or worn out, or the road may be wet with rain. If the car is not positioned within its lane, there will be alerts to make the driver aware. Should the car keep drifting out of the lane, LKAS will start and the steering wheel will receive a slight turning action to guide the car back into the lane. Like ACC, this feature can also reduce driving fatigue on long journeys.

RDM operates like LKAS except it is for a more extreme situation such as when the car is about to leave the road unintended. The system will apply steering torque to bring the car back into the lane but if that is not likely to work, braking action may also occur to prevent further departure from the road.

AHB is a straightforward system which just switches the headlights between high and low beams automatically. When driving at night, the illumination should be maximised as much as possible and this is usually with high beams. However, they can dazzle oncoming drivers so they need to be switched low beams. AHB takes away the need for the driver to do this and the lighting will be kept at maximum as much as possible. Having high beam in use also enhances the effectiveness of the camera at night.

Also of note in the safety department is Honda Lanewatch, an innovative feature which provides the driver with a view of the blind spot on the left side of the car by using a small camera mounted on the door mirror. The real-time image is displayed on the 8-inch panel in the middle of the dashboard so the driver doesn’t have to turn the head all the way to the left to see the mirror. The camera is only on when the left signal is activated.

Besides having the same standard equipment as the Sedan, the City Hatchback also comes with the ULTRA seats at the rear. This is a simple but clever idea which originated in the first generation of the Jazz some 20 years ago. Where hatchbacks usually have rear backrests that fold flat to expand the cargo volume and floor length of the boot, the ULTRA seat folds up to also create extra cabin height for carrying tall items like plants.

Besides this TALL mode, there are three other modes – UTILITY, LONG or REFRESH. For the LONG and REFRESH modes, the front passenger’s seat can also be folded flat so there is an open space from the back door all the way to the dashboard to carry a really long item or just to stretch out. The UTILITY mode is essentially like what you get in other hatchbacks with the rear backrests folded down to enlarge the boot space which can accommodate bicycles.

Performance-wise, there is the same well proven 1.5-litre DOHC i–VTEC engine. This produces 121 ps/145 Nm which is the highest in its class and the power gets to the front wheels through a CVT.

For more information on the City Hatchback V-SENSING and other Honda models, visit www.honda.com.my or any authorised Honda showroom.

Honda Malaysia’s local vehicle assembly crosses 1 million mark

© Copyright – Piston.my 2024 Trademarks belong to their respective owners. All rights reserved