Cars and shoes… in some ways, they can be considered have similar functions since both ‘transport’ people around, though in very different ways. Cars use energy from the combustion engine or electric motor to move but with shoes, you have to provide your own energy. So it’s not unusual that on World Car-Free Day (September 22), Volvo Cars Canada and Casca footwear will launch a limited-edition sneaker. Available in Canada for $198 (about RM645), the shoes have been inspired by the fully electric Volvo XC40 Recharge.

“At Volvo Cars, we are committed to setting the highest standards of sustainability in mobility and that goes beyond electrifying our fleet to transforming all aspects of our business. The shoe we have created with Casca in celebration of World Car-Free Day, is one way to recognize the many steps we are taking on our journey to climate neutrality,” said Matt Girgis, Managing Director of Volvo Car Canada Ltd.

For a carbon-neutral future

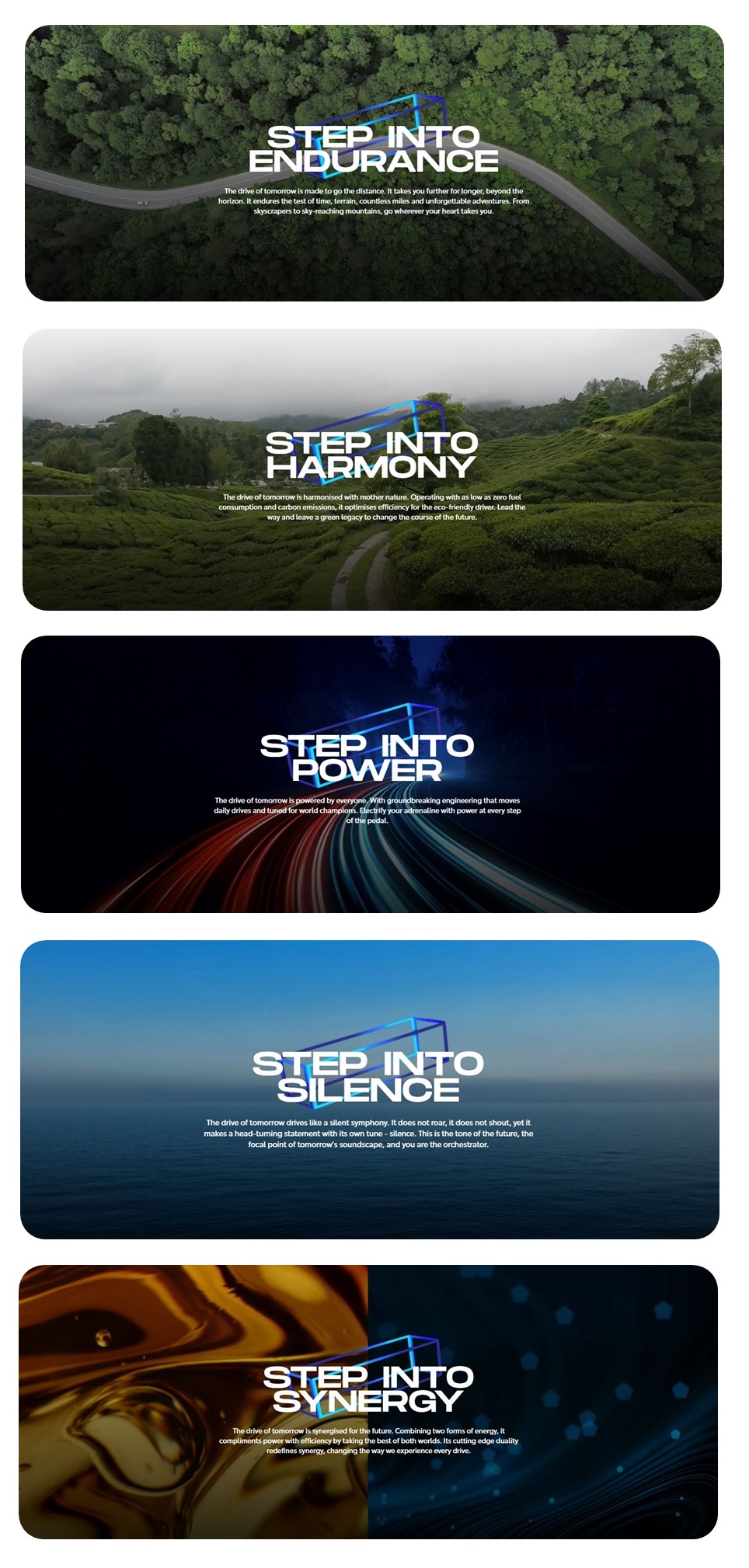

As would be expected, the shoe is all about sustainability in the long term, and both brands have a shared vision for a carbon-neutral future. On Volvo Cars’ part, there is a commitment to reducing lifecycle emissions per vehicle by 40% by 2025 and producing only fully electric vehicles by 2030. Casca’s adoption of water-based, low-energy UV treatment processes coupled with their 2-year product warranty are a testament to their ‘buy less, waste less’ philosophy.

“The Volvo XC40 Recharge was designed to reduce environmental impact, so it was the perfect inspiration for the shoe,” said Kevin Reid Lead Director and Co-Founder, Casca. “Through this collaboration, we’re also celebrating many design firsts – our first shared design, our fastest production to market, and new recycled materials we’ve never used before.”

Scandinavian influences

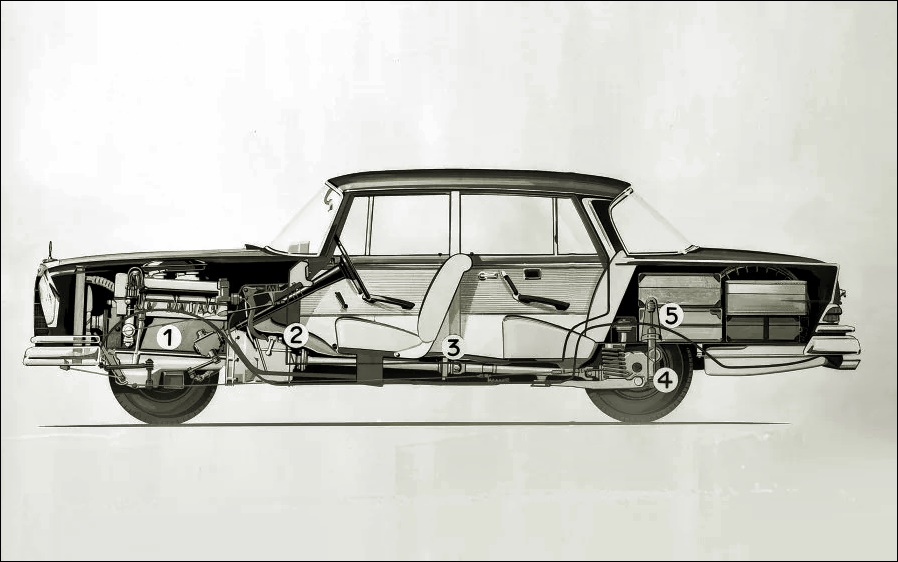

The goal was to create a shoe rooted in conscious design. Scandinavian influences of the XC40 Recharge were purposefully integrated for a collaborative new interpretation of Casca’s trademark clean lines. For instance, the ‘Thor’s hammer’ headlight influence can be seen in the linework and panelling, delivering a more performance-inspired aesthetic to Casca’s popular Avro silhouette.

The Swedish flag is represented on one shoe tag, while the classic Casca yellow can be seen on the other, honouring the collaboration between the two brands as well as minimalist, Scandinavian design.

Recycled materials

Of course, an important aspect of the shoe is how it is made and its environmentally-friendly credentials come from having 10% of each sole made from recycled car tyres, the first time this material has ever been used in a Casca shoe as part of an intentional repurposing and recycling of materials. Furthermore, 7 recycled plastic bottles are used to make the yarn for each breathable, flexible knit upper.

Those two features are a preview of some of the initiatives by both companies. By 2025, Volvo Cars aims to increase the share of recycled and bio-based materials in their vehicles by 25%. By 2022, all of Casca’s knit uppers will be made from recycled or renewable materials.

“We know that being advanced isn’t just about great design and technology; it means implementing ethical and sustainable practices,” said Braden Parker, CEO and Co-Founder, Casca. “This is just one of many similarities we see between our brand and Volvo Cars, we both want to create something with intention that lasts.”

Mazda x Mizuno driving shoes enhance Jinba Ittai for drivers