As the pace of automotive development speeds up, improvements to many areas of a car occur much faster than before. During the period of one generation of a model, there can be many technical changes which can enhance performance or efficiency. In the past, carmakers might wait for the next generation to incorporate these changes as they might involve changing hardware, which can be costly and time-consuming.

With modern cars having many more electronic systems, the process of updating doesn’t have to wait so long. New software can be loaded into the system ECUs and the car can be updated right away. That’s what Porsche will be doing with the more than 75,000 Taycan electric sportscars now in use around the world. And instead of incremental updates, it is making one comprehensive update that will make all those cars similar in software status to the 2023 model year. It’s just like the updates you get for your smartphone which sometimes introduce new or improved features.

Improvements in many areas

Depending on when their vehicle was delivered and the specific features, owners will benefit from an increase in powertrain efficiency as well as new functions and improvements in the Porsche Communication Management (PCM), Porsche Connect and assistance systems. The uPdate also includes the option of having additional functions and equipment unlocked after purchase (known as ‘function on demand’ or FoD), an approach now being market-tested by some carmakers.

“This campaign will allow our customers to benefit from the continuous further development of the Taycan. We have extensively optimized the model series in almost every respect since 2019,” said Kevin Giek, Vice-President Model Line Taycan, during a media briefing online two days ago. “New functions have been added and others have been revised or tweaked to further enhance the customer experience.”

The uPdate is free for owners but they have to bring their Taycan to an authorized Porsche service centre. It’s probably too extensive for an over-the-air (OTA) update which would not require the visit, but Mr. Giek said that this uPdate will enhance the OTA capability of all Taycan models. Presumably, that means that later updates can be broadcast to owners so they don’t need to go to the service centre.

The precise scope of the uPdate, and the duration of the service centre visit, will depend on the model year. Since the car was launched in 2019, many improvements have been made and for the older cars, more software may need to be updated.

Main uPdates at a glance

Powertrain: While in the ‘Normal’ and ‘Range’ driving modes in all-wheel drive models, during partial load operation, the front electric motor is almost completely disconnected and de-energised. While coasting and at a standstill, both axles are free of drive torque. The electric freewheel reduces frictional drag losses which can increase the range.

The all-wheel drive indicator is now shown as an energy-flow indicator in the central display. This makes the current operating status of the drives easier to see. The energy recuperation strategy has also been optimized. The automatic recuperation setting is retained even when the driver changes the driving programme.

Thermal management: The battery packs are sensitive to temperatures and operate at their best within a certain temperature range. The new software will enable better conditioning of the battery pack, especially at low outside temperatures. This will enable the Taycan to be rapidly charged more frequently overall and over a wider range of battery charge levels. The waste heat from the electrical components is used even more than before for this conditioning. For those Taycans of the 2020 and 2021 model years, the improvement will be in greater range and shorter charging times.

Porsche Communication Management (PCM) and Porsche Connect: These systems get new functions, a colourful tile design on the start screen, and even greater ease of use. For the 2020/2021 models and up to mid-February 2022 production, the uPdate optimizes the voice control and integrates the Spotify app. Android Auto is also available wirelessly.

Charging stations can be filtered and selected in the navigation system based on charging capacity. Drivers of 2021 Taycan with a head-up display will also have an optimized view of the navigation map, among other elements. The display contents have been expanded, presenting additional information. For all Taycan models prior to the 2023 model year, the on-board operating instructions can now also be used via voice control.

Assistance systems: The uPdate will adjust some systems to support the driver in even more situations. For example, the sensors of the ParkAssist function will work with a greater range. The search for available parking spaces has been improved as well, so that even smaller spaces are offered to the driver as an option.

Onboard charger retrofit

The 22 kW onboard charger has now become available for retrofitting as an extra-cost offering. With up to 22 kW of charging capacity, the more powerful variant charges the battery significantly faster. In Europe and North America, the retrofit also includes activation of the Plug & Charge function. This enables convenient charging and payment without a card or app. As soon as the charging cable is plugged in, the Taycan establishes encrypted communication with the Plug & Charge-compatible charging station. The charging and payment processes then start automatically.

“An exercise as big and comprehensive as this one has never been done before for any of our combustion engine models. Following this uPdate, anyone driving a Taycan from early in the car’s production run will be pleasantly surprised by how much has developed on the vehicle side since then,” said Mr. Giek, adding that, internally, Porsche refers to this as the ‘uPdate’ (with a capital ‘P’) because the 2023 model year, which started in July 2022, bears the letter ‘P’.

Porsche Taycan Driven by Karamjit Singh – Behind The Scenes Story

While Skoda does not compete in the top class of the World Rally Championship, it has been very successful in other segments of the Rally Pyramid, notably in the WRC2 category. Its FABIA is among the most successful rallycars in the world with the rally versions – FABIA Rally2 and FABIA Rally2 evo – having dominated the category from 2015 to 2022. The more than 450 units built by Skoda Motorsport collected 1,710 victories by April 2022, including 4 victories in the legendary Monte Carlo Rally.

Newly developed engine

When it was time to move on to a new generation, the development team at Skoda Motorsport has much experience to draw upon. With the new FABIA RS Rally2, customer teams will have a much more competitive car with a new engine, improved handling, better electronics and enhanced safety features. The new engine is a 1.6-litre turbocharged unit based on the 2.0 TSI from the Volkswagen Group EA888 engine family (used in the RS models).

The output of 289 bhp/430 Nm goes to all four wheels via a sequential 5-speed transmission. Although there is a mechanical clutch, it is only used for starting, parking or when driving slowly. For optimum acceleration on tight, winding rally stages, the FABIA RS Rally2 has a relatively short gear ratio, offering a top speed of around 200 km/h.

To prepare the new FABIA RS Rally2 for action on the rally track, test-drivers subjected prototypes to extensive tests on asphalt, gravel and snow for almost a year. This included trials in the Czech Republic, France, Italy, Croatia, Germany, Belgium and Spain, as well as under extreme winter conditions in northern Finland since mid-2021.

The gruelling test programme validated the special braking system and precisely balanced chassis. In addition, the electronics and controls were also tested to meet the demanding conditions during a rally. Also tested was the special 82.5-litre fuel tank and shock-resistant rubber which meets the FIA’s regulations. Additional protection is provided by a carbon/kevlar composite cover and an absorbent layer on the underside.

Sustainable fuel requirement

Throughout the 2022 season, 100% sustainable petrol will be used by competing cars in the WRC. This is based on modern raw materials and high-purity renewable components. The bio-fuels are derived from biological waste and synthetic e fuels. These are produced using renewable energies that enable electrolysis from ‘green’ hydrogen as well as CO2, which is extracted from the air and industrial processes. The 100% renewable petrol is then mixed in a laboratory without any fossil-fuel components.

Some of the components used in rally vehicles differ significantly from their counterparts in production vehicles. Instead of having up to nine airbags and numerous electronic assistance systems like those found in the production FABIA, the new FABIA RS Rally2 relies purely on mechanics in many aspects. It also features specialised components, such as a roll cage and specially protected fuel tank.

Also unlike the production version sold to the public, the rally version only uses sensors for engine management and displaying the brake pressure, steering wheel position and fuel. The sensors merely provide information; with the production model, they perform any control functions. Only the engine control unit uses sensor data to ensure that it functions optimally in all driving modes and various weather conditions.

In a rallycar, the brake system can save valuable tenths of a second in the fight against the clock. The stronger the deceleration, the later the drivers can brake into a bend. In hard braking manoeuvres, the brake discs easily reach temperatures of more than 700 degrees C. To ensure efficient cooling at all times, the FABIA RS Rally2’s brake discs are internally ventilated, and an optimised brake cooling system is also available for gravel and asphalt stages.

Protecting the crew

Skoda Motorsport engineers have developed a roll-cage which has a total of 35.8 metres of high-strength chrome-molybdenum steel tubing and is welded to the chassis during body construction. The side panels and roof are then mounted over it. This procedure allows for even greater manufacturing precision, as well as a better fit and connection to the body.

The chassis is also engineered to meet the extreme demands of rallying. Compared to the previous model, the suspension stroke of the dampers is now longer and the MacPherson struts are stiffer. In addition, friction in the dampers is reduced. The longer wheelbase also prompted the development of new suspension kinematics.

More downforce generated

Paying attention to detail, the designers managed to almost double the downforce compared to its predecessor – an enormous advantage on the track, as greater downforce facilitates higher cornering speeds. For regulatory reasons, there are no active aerodynamic parts such as the radiator louvre from the production FABIA.

The same air curtains as in the front bumpers of the production car guide the airstream closely and aerodynamically over the body and wheels. They increase the downforce in combination with new side skirts, which prevent air from flowing underneath from the side. Incorporating a front splitter across the entire lower edge of the front bumper, they ensure optimum aerodynamic efficiency at the front.

Several aerodynamic components have been specially developed for the FABIA RS Rally2. In addition to the wider front and rear fenders, the newly developed rear wing increases the downforce. A small spoiler lip, the so-called Gurney flap, serves as a tear-off edge and also improves the downforce. The airflow over the roof is optimised thanks to a centrally positioned air scoop, which simultaneously supplies fresh air to the cockpit.

Support for customer teams

Skoda Motorsport has been supporting numerous customer teams in international rallying since 2020. The teams receive support that includes a comprehensive supply of spare parts and technical support, even at events. Additionally, Skoda Motorsports offers revision work on engines, transmissions and chassis components. Teams taking part in the WRC can also using Skoda Motorsport’s support truck equipped with an array of spare parts. It is available at selected WRC rounds and certain events in the European Rally Championship.

Fully electric Skoda RE-X1 Kreisel rallycar homologated for Austrian Rally Championship

Although wind tunnels have been associated with aeronautical research and development, such facilities existed long before the first aircraft flew, and they were used by scientists in the 19th century to study airflow. Aircraft designers then used wind tunnels to see the effects of different shapes that would be used for aircraft bodies and wings.

Wind tunnels were also used by other industries and by the 1930s, as cars started to go at high speeds, the wind tunnel was used to study how air flowed over their bodies. It was a Prof. Dr.-Ing. Wunibald Kamm at the Technische Hochschule Stuttgart in Germany who was the first to use a wind tunnel for aerodynamic design studies which would be pioneering.

From then on, carmakers would add aerodynamic studies to the development process of a new model, using scale models in small wind tunnels and full-sized models in larger tunnels. Various types of equipment measured airflow so that it could be optimised because it was understood that smoother airflow could improve performance and also reduce noise levels. By having a wind tunnel, the engineers could also study the behaviour of the car design (eg stability) at high speeds without actually having to drive the prototype on the track.

In earlier years, carmakers didn’t yet have their own wind tunnels, so they used those in other research facilities. In time, some started to build their own so they could conduct testing with more secrecy and also without having to pay for renting facilities. Some built small tunnels and some built big ones, depending on how much they could spend.

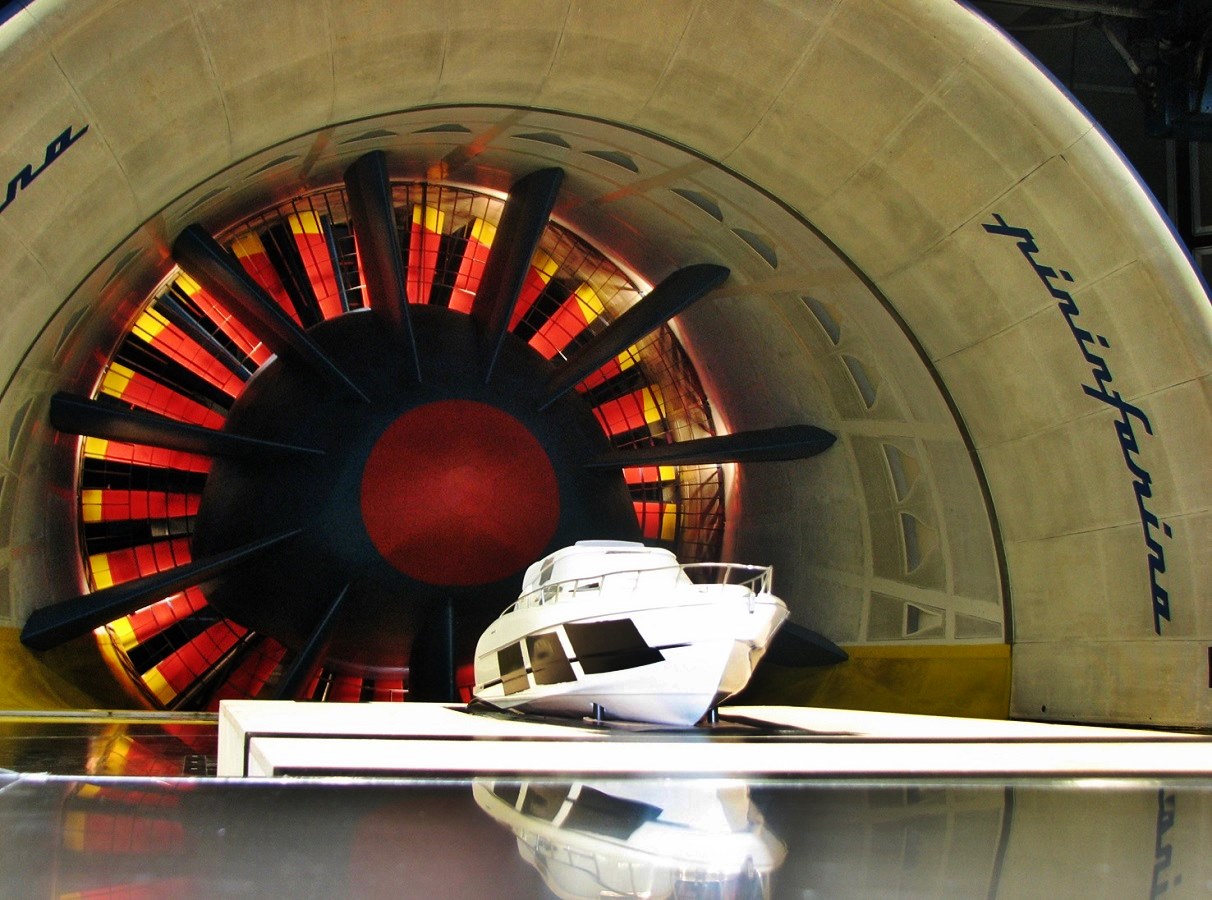

Pininfarina, the automotive design consultancy, also decided to build its own wind tunnel and it was large enough to test full-sized vehicles. At the time it began operations, it was Italy’s first wind tunnel to be built for testing full-sized cars, and one of only seven in the world. That was in the year 1972 and this year sees it celebrating its 50th anniversary.

“Without a doubt, Pininfarina has a real passion for aerodynamics. And it’s a passion that has lasted more than 50 years, long before my father decided to build the structure. It all began with my grandfather Pinin, whose visionary intuition in aerodynamics is exemplified since the Lancia Aprilia Aerodinamica produced in 1936,” said Chairman Paolo Pininfarina, whose father was Sergio Pininfarina.

While it was initially used for motor vehicles, Pininfarina’s wind tunnel would become a powerful tool for testing and developing products across all sectors in which the company is fully involved. These include aircraft, high-speed trains, yachts, buildings, wind engineering, industrial design and even sporting goods. With the advent of electric mobility, there is even greater emphasis on aerodynamics as well as aeroacoustic development.

It is one of the few wind tunnels in the world to have a TGS – Turbulence Generator System – able to create various conditions of controlled turbulence associated with gusts of wind, overtaking manoeuvres, cross-winds and vortices generated by cars ahead.

There is also a Ground Effect Simulation System allows reproduction of real vehicle motion conditions. This is achieved by having 4 rollers and 3 mats to allow the wheels of the vehicle and the ground to move at the same wind speed. This system was developed to make the tunnel test conditions as faithful as possible to the road conditions, and to analyze the movement of air underneath.

While most cars have closed cabins, there are also convertibles with open tops as well as the increasingly popular fitment of sunroofs that create an opening on the roof. These all have significant implications on airflow and noise generation, as those who have been in such cars will know. In the wind tunnel, the turbulence generated can be studied and solutions developed to make things more comfortable.

When it first started operation, the wind speed inside the tunnel was less than the 250 km/h maximum of today. It was upgraded with the addition of 13 fans, with each fan able to spin at a different speed or have a different blade pitch. Noise levels were also reduced allowing better aeroacoustic studies with new noise measuring techniques. Aeroacoustic tests are becoming a fundamental element for increasing driving comfort, particularly for hybrid and battery electric vehicles.

The wind tunnel is equipped with three external microphone arrays and also cameras, helping to identify the sources of noise and consequent definition of countermeasures. Noise Vision and Beam Forming support enables visualization to aid analysis. In addition, the wind tunnel is also equipped with 4 acoustic dummies for internal acoustic comfort evaluation.

“The Wind Tunnel has given our company a considerable competitive edge, being the only design company to own one. Born as a tool with which Pininfarina developed its own projects, today it’s a strategic asset for the group, thus expanding the portfolio of services that we offer to the market: an activity that supports other sectors beyond the automotive, from transportation to architecture, from nautical to industrial design,” said CEO Silvio Pietro Angori.

Sunshine has energy which can be converted into electricity. With that energy source shining down on our planet daily for around 12 hours, it would seem that we should make use of it to power the many different types of modern equipment that we use today. And that is already happening with solar panels collecting sunshine which is converted to electricity for industrial use as well as things like water heaters in homes.

Now that there is this rush towards electrification of cars, why not use solar energy which is unlimited – and costs nothing? Manufacturers are spending billions in developing electric vehicles and surely they would have been able to come out with solar-powered cars by now. After all, they can even use hydrogen in fuel cells to generate electricity which is then used to power cars.

Why are there few solar cars?

The problem is that the technology is still not advanced enough to generate the amounts of electricity constantly to keep a car running. Maybe in the Star Trek age another 250 years in the future, a small solar panel will be enough to power a car indefinitely but at this time, an array of solar panels on a medium-sized car would need around 8 days to fully charge a battery pack of 70 kWh. So it’s a technological issue that is keeping development of solar-powered cars at a snail’s pace for now.

But there are many ongoing efforts and such cars are ‘just around the corner’. In fact, by early 2023, one company might be able to start delivering solar cars to people who have booked one. The company is Aptera, a car company that started in 2005 in California, closed down and was revived in 2019 with a plan to make a battery-electric vehicle (BEV) that also uses solar power primarily, and a battery pack as a range-extender.

The idea of using solar power as a supplementary energy source for cars is not new. Companies like Toyota and Hyundai have put small solar panels on the roofs of some models for additional electricity to power ancillary equipment.

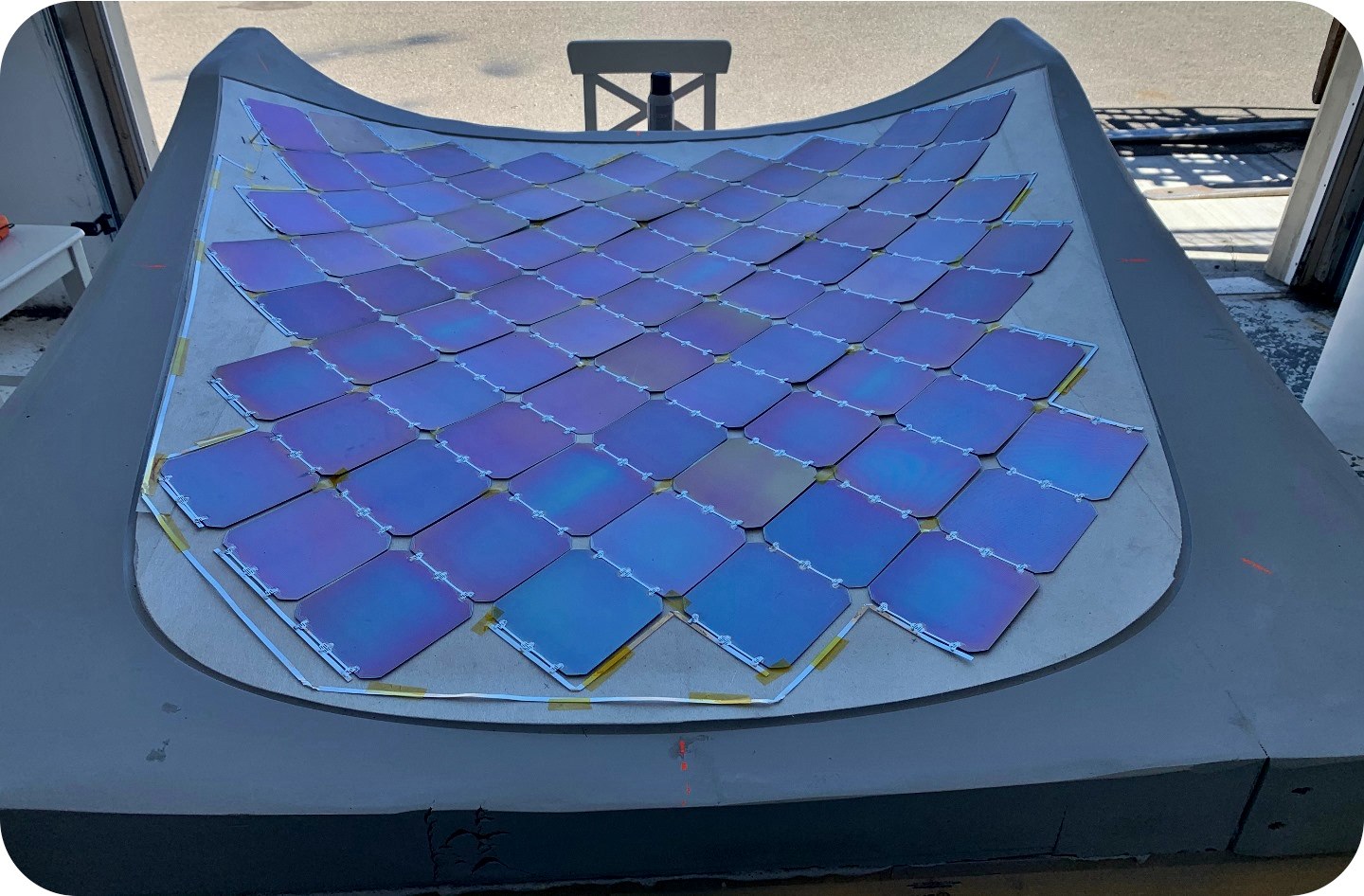

Up to 1,600 kms range

Aptera’s solar electric vehicle (sEV) will require no charging for most daily use and the company claims that it can cover up to 1,600 kms per full charge if the battery pack is used as well. This is achieved with its ‘Never Charge system which uses 180 cells on diamond-shaped solar panels covering 3 square metres of the car’s body. These can collect sunshine to convert to as much as 700W which would be good for 64 kms of driving per day. Those 64 kms of essentially free range are collected by over 3 square metres of solar panels on the bodywork.

If you’re just driving around town daily, then you really would not need to recharge. But for longer distances, then there is a battery pack which has stored electricity to provide the extra range required. And Aptera says that recharging can be done with a household power supply, though how long it will take is not mentioned.

Propulsion is by 3 liquid-cooled in-wheel electric motors (two in front, one behind) that can give an acceleration time of 3.5 seconds from 0 to 96 km/h and a top speed claimed to be almost 180 km/h. For stability, there will be all-wheel drive and vectorized torque control.

Three wheels, instead of four

To maximize use of the electricity available, the sEV has to be as light as possible, requiring less energy to move. In fact, having three wheels instead of four is partly due to saving weight. At between 818 kgs to 1,000 kgs, the vehicle is said to weigh 65% less than other EVs on the market today. Aptera’s engineers have also used many different example to reduce energy loss, and by eliminating the fourth wheel, the contact point for friction and potential energy loss is lessened.

The body is built with ultra-lightweight composites and its arched shape mimics the physics of an eggshell to create a safety cell that is claimed to be much stronger than steel.

Aerodynamic efficiency of 0.13 Cd

Besides light weight, the other important factor is aerodynamic efficiency or how slippery the shape can be so that wind resistance is minimized. Less energy will be needed to overcome the wind resistance so performance will be better and at the same time, the energy saved can be used for extending range.

The aerodynamic form of the vehicle, which has a Cd of 0.13, is inspired by nature. The teardrop-shaped central body allows air to flow around it to ‘follow & copy’ that shape. This means airflow contacts the body at a certain angle around the front wheel area, as the air is being bent around the tapered nose. The wheel covers are tapered inward and the rear is tapered outward, making the overall shape more aligned with the main bodywork.

At the single rear wheel, the story is different. The wheel is positioned at the centreline of the vehicle and optimizations were applied to the bodywork in front of the wheel. Guiding the air in such a way that it avoids hitting the exposed part of the tyre, providing gains in terms of aerodynamic efficiency.

Intelligent cabin packaging

The sEV is a small vehicle and seats only two. However, intelligent packaging has ensured that those two people can carry a lot of gear or a lot of shopping from the supermarket. The layout has both occupants side by side, rather than in a tandem position like a motorcycle (as some solar vehicles have been designed). Much of the thinking behind the interior has been with manufacturing simplicity and flexibility in mind.

As would be expected, there are storage areas for the stuff we all carry these days as well as things like wireless charging pads. Environmentally-conscious materials are used, such as biodegradable and plant-based leather, recycled PET and 3D knit materials, bio-based plastic thread and recycled felt.

Pricing to be from US$29,500

Aptera is confident of moving into the production phase by the end of this year as it has received US$40 million (about RM178.3 million) in crowdfunding and commitments. It has also been accepting $100 (RM446) deposits from interested customers (it says there are already 25,000 reservations) and expects to price their first solar vehicle from US$29,500 (about RM131,500).

Free sunshine helps Proton save up to RM5.85 million on electricity costs

With Singapore being just a short drive across the two connections over the Straits of Johor, Malaysians have long been driving into the republic for holidays or business purposes. Daily too, thousands of Malaysians enter Singapore to work as well. As in Malaysia, possession of a valid driving licence is necessary to drive a car around Singapore and it has been fortunate that the Malaysian driving licence has been accepted and Malaysian-registered vehicles can also be driven in for short periods.

For those who are staying there for much longer periods (more than a year), it is necessary to have a Singapore driving licence. To make things a bit more convenient, the Singapore authorities now allow applications for conversion of the Malaysian licence to a Singapore one to be done online. For now, it is a trial program which is aimed at reducing the waiting and processing times at the Traffic Police headquarters in Singapore.

As with the Vehicle Entry Permit (VEP) which has applied for online, the move is also in consideration of these times where physical interaction should be minimized to avoid spreading the COVID-19 coronavirus. By moving processes online, the time that people have to spend face to face can be reduced.

The online application is only the first step in the process, but it is useful to ensure that all conditions are met before actually going to the office. Thus the applicant’s time won’t be wasted, and the police also will not waste their time. If all conditions are satisfied, then the applicant will have to personally deliver copies of relevant documents and make payments. This will only be after a period of 10 days from submitting the application and a specific time and date will be provided.

If everything goes well, successful applicants should get their Singapore driving licence within 10 days. It is also possible to obtain a Digital Driving Licence for those who have a SingPass account. This is valid as a licence for inspection so you can start driving more quickly.

Incidentally, all applicants must also have a valid International Driving Permit (IDP) which Malaysians can obtain from the JPJ. The IDP is valid for one year and can be used in almost all countries. Applicants must also sit for the Basic Theory Test (BTT) at any of the driving centres in Singapore

For further information, visit the Singapore Police Force website.

Latest information for those planning to drive to Singapore when the border reopens next month

© Copyright – Piston.my 2024 Trademarks belong to their respective owners. All rights reserved