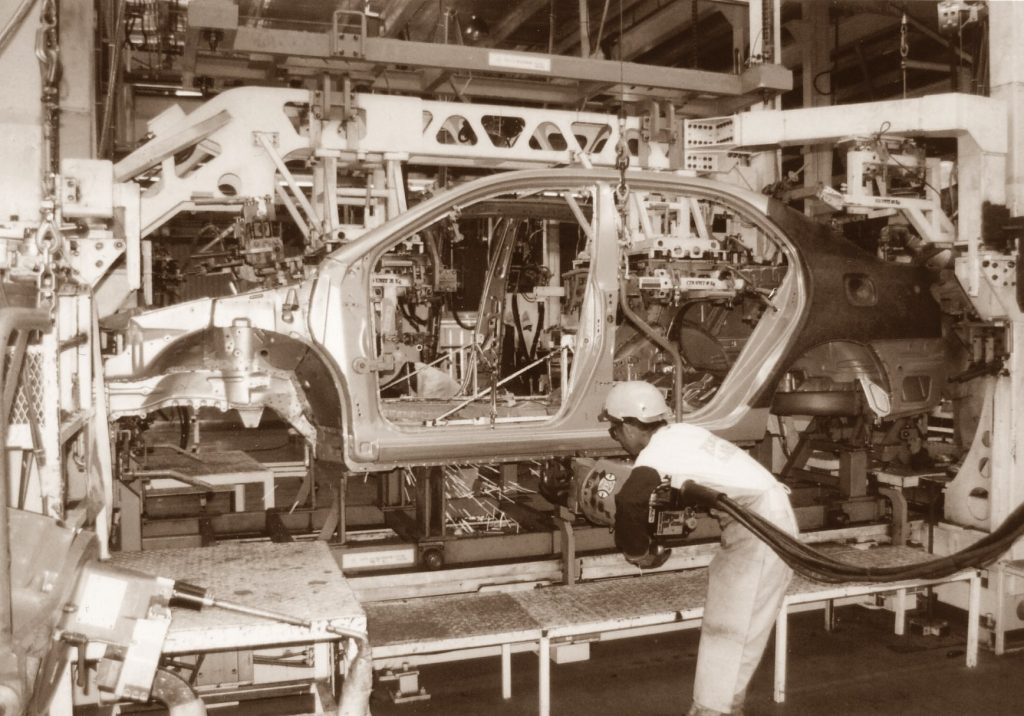

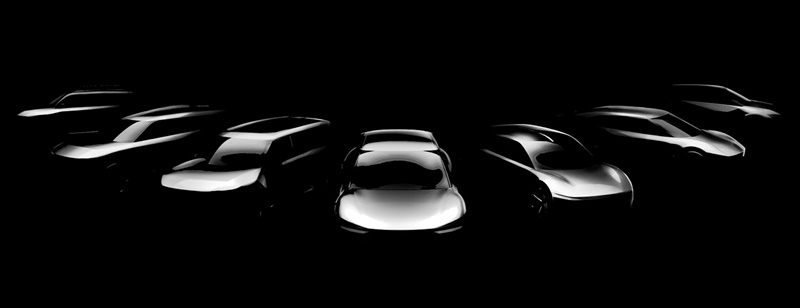

At the 2022 Monterey Car Week this weekend, Aston Martin will present the DBR22, a V12-engined 2-seater coachbuilt design concept. The creation of the DBR22, which celebrates the marque’s bloodline of open-cockpit sports racers, is the latest in a long line of projects handled by its in-house bespoke division, Q by Aston Martin.

With classic proportions and immaculate, muscular curves, the DBR22 follows Aston Martin’s lifelong lineage of world-beating 2-seater open-cockpit sportscars such as the DBR1 and DB3S. And by mating the classic art of coachbuilding with advanced materials and cutting-edge manufacturing technologies, the design concept perfectly blends design purity, engineering precision, heart-pounding performance and true passion.

The DBR22 showcases a completely new body from Aston Martin’s designers. Its form is created from a minimal number of body panels to create a more sculpted, muscular presence. A particularly noteworthy feature is the entirely new front grille which incorporates a unique carbonfibre design in place of the usual veins seen on series production Aston Martins.

This design takes inspiration directly from the DBR1 and DB3S, giving a unique identity; one which clearly draws from Aston Martin’s heritage but uses this inspiration to create a truly contemporary design.

The bonnet features a dramatic horseshoe vent, recessed to aid airflow from the 5.2-litre V12 Twin-Turbo engine (715 ps/753 Nm) that sits beneath it. This long, unbroken bonnet line draws the eye back towards the cockpit, over the lowline wind deflector and delicate mirrors, which are mounted to the tops of the doors on slender, wind-cheating carbonfibre arms.

Sitting perfectly within the wheelarches is a set of all-new 21-inch alloy wheels featuring a unique 14-spoke design created especially for the car. There is a motorsport-derived centre-lock hub which is also available to spec from an extensive colour pallet.

The DBR22 also showcases an entirely bespoke paint colour, developed specifically for the occasion using ‘Paint to Sample’ – an exclusive option available through Q by Aston Martin, demonstrating again the vast design possibilities attainable through the bespoke service.

The cockpit continues the fusion of classic and contemporary approaches with many unique components and an extensive use of both leather and exposed carbonfibre. With architecture defined by the all-new dashboard and sleek infotainment displays, it sets the tone for a clean, uncluttered environment.

Though taking inspiration from Aston Martin’s competition cars, the DBR22 is no bare-bones racer inside. Supple aromatic hides swathe the contemporary dashboard, the carbonfibre performance seats and extend over the tops of the doors to create an inviting hint of the interior.

Rising from behind the seats are twin nacelles which smooth the airflow behind the driver and passenger’s heads. At the rear is an unmistakable horizontal light graphic courtesy of the slim, full-width light bar made specially for this application. Beneath it sits a perforated panel to allow hot air to exit the tail.

This beautifully sculptural piece is yet another unique highlight of the DBR22 intriguing design. Together with the smoothly integrated diffuser and pair of large diameter exhaust tailpipes, the DBR22 has incredible road presence, perfectly capturing the raw emotion of the driving experience.

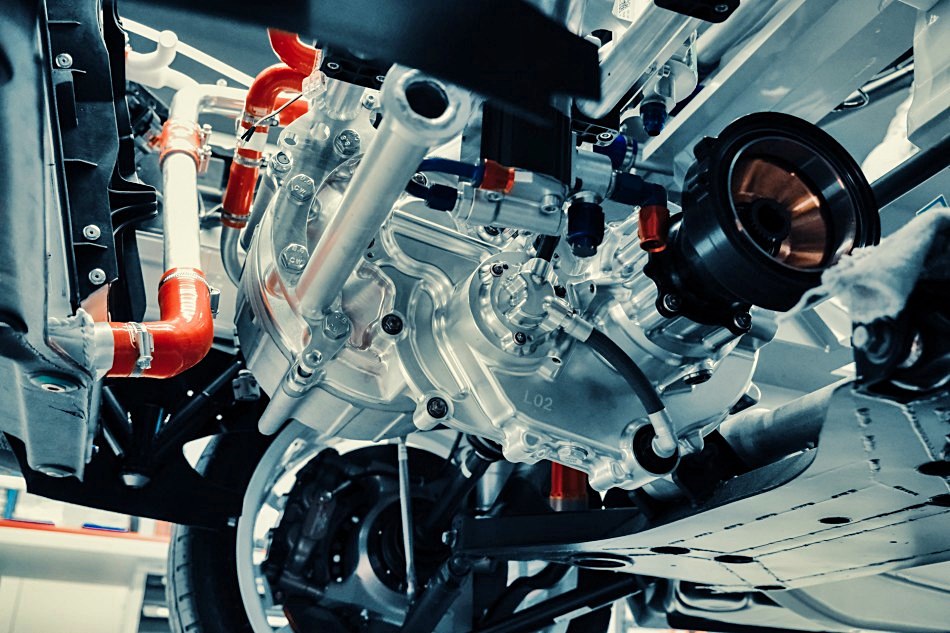

Unique calibration of the engine and 8-speed paddle-shift automatic transmission uses torque shaping to give the DBR22 a manner and delivery said to be unlike any other model. A pinned steering column brings greater accuracy but also provides more detailed feedback so the driver can build a more accurate picture of available grip.

Attention has also been paid to the DBR22’s chassis structure. Unique front and rear shear panels further increase tortional rigidity, with a bespoke calibration for the adaptive dampers providing precision and pliancy for a blend of body control and ride.

The DBR22 also features a 3D-printed rear subframe – the first time Aston Martin has introduced such a method. The component is made from multiple 3D-printed parts printed from aluminium, which are then bonded to form the finished subframe. The advantages are clear, with a significant weight-saving and no reduction in stiffness, plus the ability to make special parts for ultra-low volume models, where required.

“We set our design systems to ‘hyper-drive’, pushing the exploration of formalism further and endeavouring to express a future in the here today. Where could we go with the surfaces, proportion and form. Combining this approach with advanced process, technology, and materials, we’ve effectively modernised our racing bloodline and created a new pedigree. DBR22 is a hot-blooded, purebred Aston Martin sportscar full of speed, agility and spirit, and a machine that we think will be the basis of many of tomorrow’s icons,” said Marek Reichman, Aston Martin’s Chief Creative Officer.