For those following auto industry trends, it would appear that the future has to be electrified; first, hybrids with a combustion engine and electric motor, and then just an electric motor alone. It’s considered the only way to address climate change which is blamed partly on exhaust emissions of motor vehicles. Increasingly stringent regulations have made it more and more challenging for manufacturers to develop combustion engines to meet tougher standards and it seems that going electric is the only solution.

Perhaps it is – in the longer term – but for now, the technology is still expensive and hybrid powertrains are just beginning to have cost levels that can reach a much larger number of consumers than fully electric vehicles or battery electric vehicles (BEVs). Furthermore, in many countries, the infrastructure to support BEVs is still not sufficiently developed so it will be inconvenient and impractical owning such vehicles that need regular recharging. In Malaysia, for example, there are around 400 recharging stations at the moment – versus around 3,700 stations selling petrol and diesel.

For these reasons, some manufacturers are looking at other approaches which can give consumers choices. Five Japanese manufacturers – Kawasaki, Mazda, Subaru, Toyota, and Yamaha – are collaborating to find ways to continue using internal combustion engines in a way that can meet stringent regulations and still aim for carbon neutrality.

They are not against full electrification and are developing BEVs too (Toyota will spend 4 trillion yen during this decade on BEV development), but they also think of customers in less developed countries where BEVs will be too expensive. Such people still need transport, so they will be provided vehicles with powertrains that are sufficiently ‘green’.

Realistic alternative approach

This alternative approach is realistic and given the combined technical resources of the 5 companies, new solutions will be found. Back in the early 1970s, when tough exhaust emissions regulations were introduced in America and forced manufacturers to fit catalytic converters, Honda was able to develop its CVCC engine which could run on low-octane fuel and meet the regulations without having a catalytic converter.

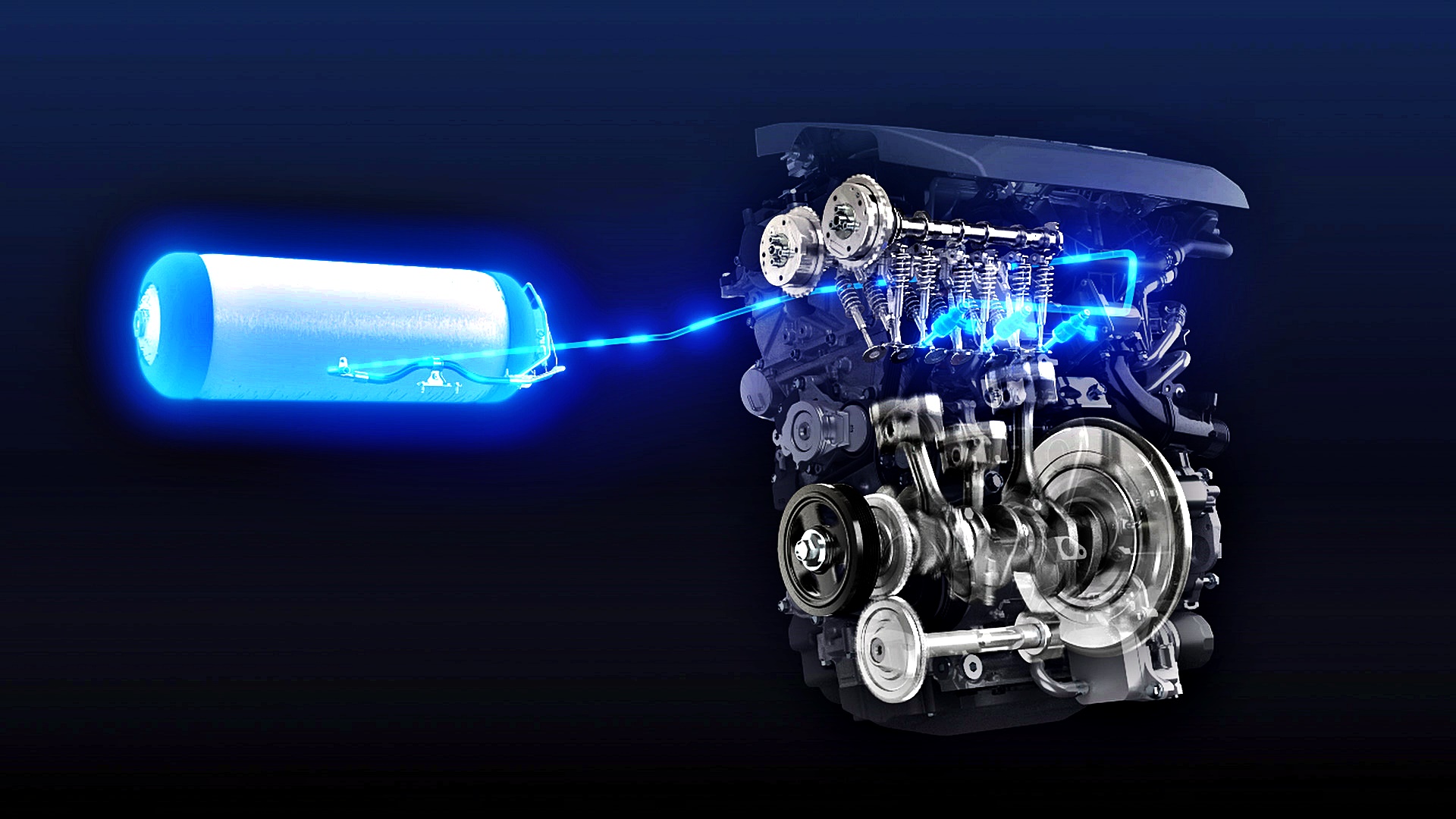

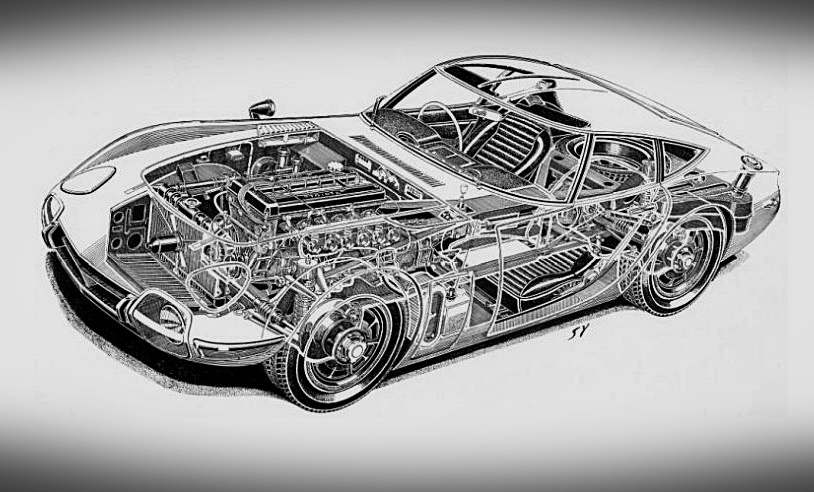

Toyota and Yamaha have been jointly working on engines that can run on hydrogen, while Mazda is working on engines that use next-generation bio-diesel. The carmaker previously developed the SKYACTIV-D turbodiesel which was a very efficient engine, and this engine is now being modified to use a 100% bio-derived next-generation fuel called Susteo developed by Japanese firm Euglena Co. Ltd.

Testing in endurance racing

The prototype engine is installed in the Mazda2 Bio concept car and part of its development will include being raced in Japan’s leading domestic endurance racing series, the Super Taikyu Series. This series, which consists of 7 rounds, starts next month at Suzuka and there will be races of 5 or 6 hours as well as a 24-hour event.

Mazda already demonstrated the potential of the 1.5-litre SKYACTIV-D powered car with Euglena’s 100% bio-based fuel made from used cooking oil and microalgae fats when the Mazda2 competed in last November’s Super Taikyu Race.

Participating in the ST-Q class with the Mazda2 Bio concept, Mazda will take part in the full series with a new silver livery. From the third round, it will also compete with a SKYACTIV-G petrol-powered MX-5 in the ST-5 production class, a class that has seen privateer teams have huge success with MX-5s over the last few years.

Multi-solution approach

Mazda is following a comprehensive strategy called the multi-solution approach, which takes into account all available solutions to reach climate neutrality and to suit individual mobility needs as well as regional conditions. It will continue to make investments in developing conventional hybrids, diesel engine models, BEV models and plug-in hybrid (PHEV) models while, at the same time, promoting initiatives in renewable fuels such as 100% bio-based fuels.

Next-generation biodiesel fuels, which are made from sustainable raw materials such as microalgae fats and used cooking oil, do not compete with food crops, which has been an issue with existing biodiesel fuels. As these fuels can also be used as alternatives to diesel in existing vehicles and equipment without any modification, no additional fuel supply infrastructure is required. Therefore, biodiesel can be expected to play a prominent role as an excellent liquid fuel source in promoting carbon neutrality.

High-performance Lexus V8 modified to run on hydrogen in Toyota-Yamaha project