After a short hiatus, Edaran Tan Chong Motor, the authorised distributor of Nissan vehicles in Malaysia is back with some exciting news, especially for those who have been anticipating the arrival of electrified Nissans in Malaysia.

The company has confirmed that models with its second-generation e-Power hybrid powertrain will be arriving on Malaysian shores from the fourth quarter of the year onwards, with either the Nissan Kicks e-Power or the Serena e-Power being the first.

So, in an effort to give us a first-hand experience on the e-Power hybrid technology and also to help us understand how the system works, how it feels and whatnot, we were given the opportunity to sample the Nissan Kicks e-Power in Putrajaya recently.

Now, before we get into the driving impressions of the Kicks, let us first dive into the e-Power hybrid powertrain system itself and understand how it works.

What is the e-Power system?

The e-Power drive system is a unique innovation of Nissan in that it is 100% motor-driven without needing to plug in and charge. Electricity is produced by a highly-efficient internal combustion engine dedicated to generating power and recharging the battery pack.

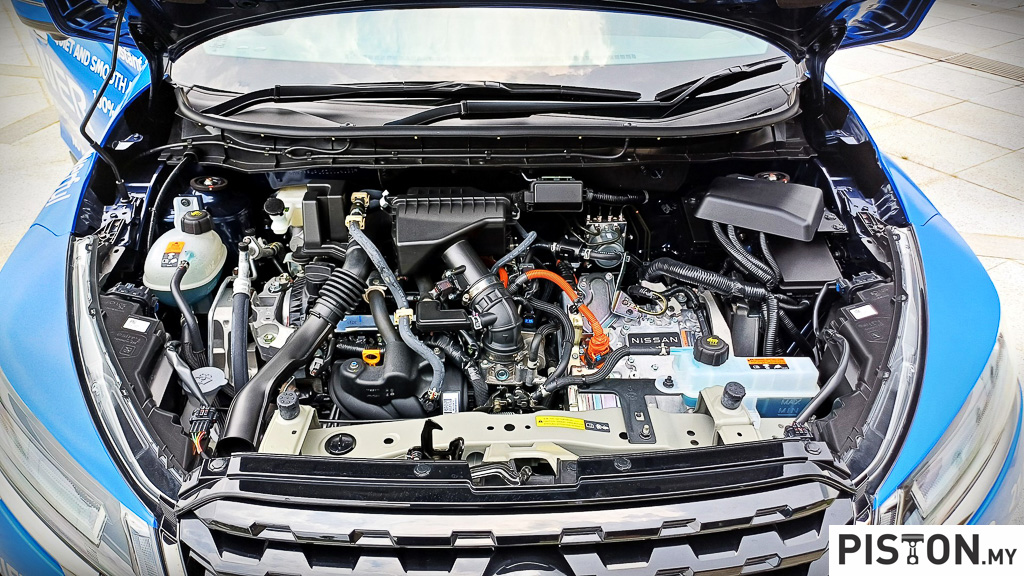

The main components of the e-Power system consist of a Lithium-ion battery, a high-power electric motor, inverter, a generator and a combustion engine with class-leading thermal efficiency.

Unlike most hybrid vehicles in which the engine is responsible for propelling the wheels when the need arises, the internal combustion engine in the Nissan e-Power system is only there to charge the battery, and nothing more.

How does it work?

At low to medium speeds, such as in urban areas, the vehicle is mainly driven by the electric motor powered by the lithium-ion battery for an EV-like performance.

When driven at high speeds where rolling noise is elevated, the engine runs at optimal RPM to generate sufficient electricity to power the motor, and when strong acceleration is required, the motor combines the electricity generated by the engine and the electricity from the lithium-ion battery to power the vehicle.

Like EVs, e-Power also offers the convenience of single-pedal driving where brake pedal operation can be reduced by nearly 70% through regenerative braking which can slow the vehicle while replenishing the battery.

What this means is that the wheels are propelled solely by the electric motor, just like a Battery Electric Vehicle (BEV). Also, the e-Power system offers an immediate throttle response as an electric motor can generate maximum torque instantaneously just like an electric vehicle.

Tuned and calibrated to be discreet, the e-Power’s internal combustion engine only operates on a fixed-point basis where the engine is at its most efficient range to generate electricity.

With a claimed fuel consumption figure of just 2.2 L/100km, Nissan says that the Kicks e-Power can travel up to 900 km on just a single tank of fuel.

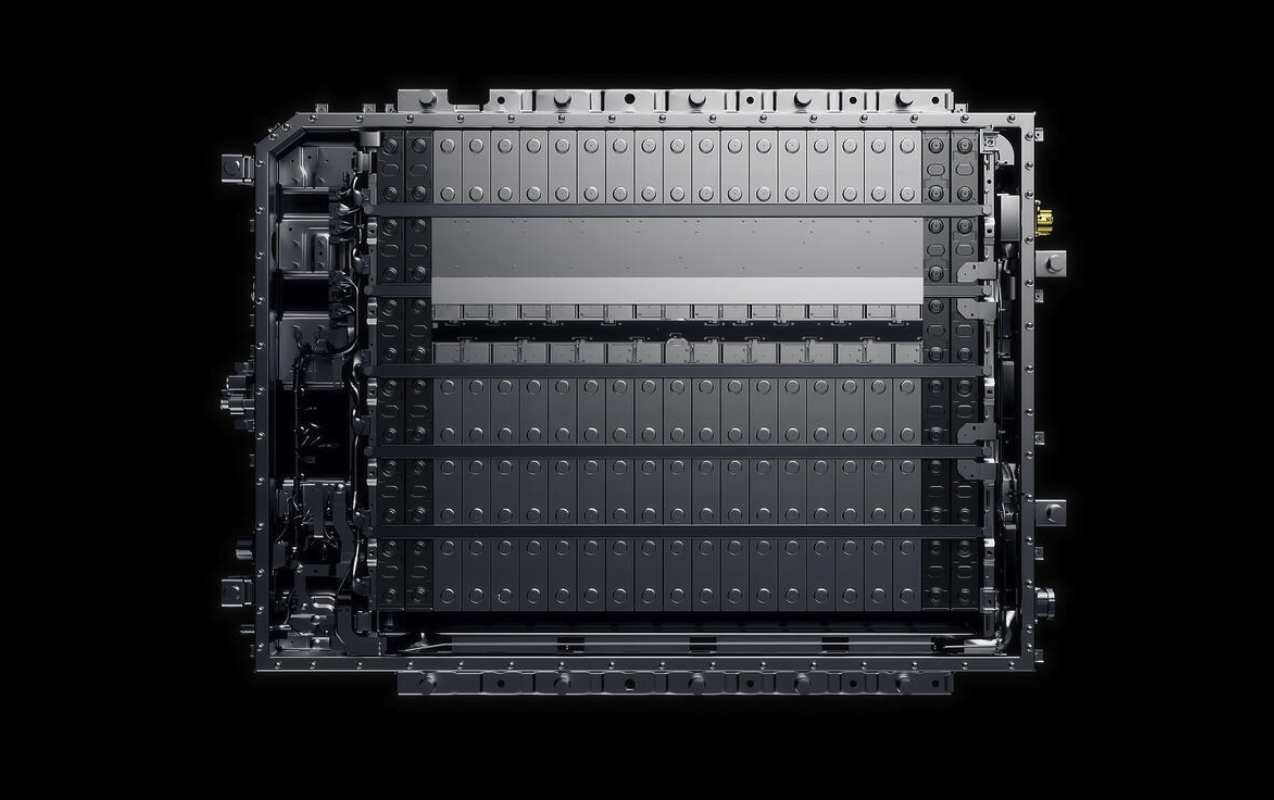

Meanwhile, the on-board Lithium-ion battery pack of the e-Power system is compact in size and lightweight in construction. Even though the battery capacity has been increased by 30% in the second-generation e-Power system which is coming to Malaysia, the overall system weight is lower and does not impact the drivability, practicality, spaciousness of the vehicle.

Origins of the e-Power system

Developed primarily for the Japanese market where there is a high demand for electrified vehicles but a lack of charging infrastructure due to the highly dense nature of the places where people live, the e-Power system turned out to be the perfect solution for the problem Japanese motorists were facing – as it is essentially a self-charging BEV without the need of plugging into a charger.

This explains why the Nissan Note e-Power, which was the first-ever model to feature the e-Power hybrid drive system, was such a big hit in Japan.

First launched in November 2016 in Japan, Nissan sold over 100,000 units of the Note in the first 11 months and swiftly took the top spot in Japan’s new car sales ranking (excluding mini cars) by the end of 2018.

Following the success of the first-generation Note, the second-generation Nissan Note was launched in November 2020, powered exclusively by the e-Power drive system.

As anticipated, the hatchback became a hot-selling model in the Japanese compact hatchback segment once again, exactly like its predecessor.

Nissan then started fitting the e-Power hybrid drive system in other models in other segments such as MPVs and SUVs, which also turned out to be successful in Japan and other markets around the world.

Fast forward a few years, Nissan managed to surpass the one-million milestone in BEV unit sales in 2023, which shows how well-received its electrified models are. As for the Malaysian market, the e-Power hybrid drive system is all set to be introduced later this year, most likely in the form of the Serena e-Power.

First impressions of the e-Power system

As mentioned above, the model that we sampled was none other than the Kicks e-Power which was showcased at the Malaysia Auto Show earlier this year.

Powering the Kicks e-Power here is a 1.2-litre naturally-aspirated three-cylinder engine that charges a 2.06 kWh battery, which powers a single electric motor that sends a maximum output of 129 PS (96 kW) and 280 Nm exclusively to the front wheels.

After driving it, we feel that the Kicks e-Power hybrid offers a driving experience that is almost identical to a full-blown BEV compared to any other hybrid model in the market (PHEVs included).

This is because the e-Power hybrid drive system allows you to do what we call the “single-pedal driving” which is only available in pure EVs, where acceleration and deceleration are done by pressing and lifting off the accelerator pedal. The brake pedal is only used when you bring the vehicle to a complete stop at the end.

However, the single-pedal driving system is only available in ‘Eco’ and ‘Sport’ driving modes, as you have to drive the Kicks e-Power like a conventional vehicle in ‘Normal’ mode.

Since the battery is charged every time you decelerate, the fuel range is also maximised when you’re in ‘Eco’ and ‘Sport’ mode in vehicles with the e-Power hybrid drive system, enabling it to cover up to 900km with a tank of fuel.

Even though 129 PS and 280 Nm do not sound like a big deal on paper, the Kicks e-Power packs quite a punch on the road. Not only does it get to speeds of around 140 km/h quicker than its closest rivals, but it also does it more quietly.

Unlike conventional self-charging hybrids where the wheels are primarily and directly driven by the engine, the e-Power’s intelligent control system regulates engine operation independently based on factors such as vehicle speed, road conditions, degree of acceleration and battery charge levels.

As a result, the driving experience is quiet and refined with less frequent engine operation compared to conventional hybrids.

It also felt lighter and more agile than conventional hybrid models like the Honda HR-V RS e:HEV and the Toyota Corolla Cross Hybrid. While those who prefer lightness and agility would absolutely love the Kicks e-Power, drivers who prefer a hybrid with heavier steering may not enjoy it much.

We loved it though, as the zippiness and agility of the Kicks e-Power makes it ideal for daily driving in Malaysia where we are constantly manoeuvring through crowded business centres, shopping mall parking lots and whatnot.

The seamless power delivery, the silence, and the single-pedal driving system of the e-Power hybrid drive make it feel just like an EV. The only difference is that the battery is smaller and charged by the engine, compared to an EV’s larger battery which is charged by a plug from a wall box.

Another advantage of Nissan’s e-Power system is that it helped maximise cabin and luggage space, thanks to the compact design, and the lack of components that send power from the engine to the wheels such as the clutch and a conventional transmission.

In summary, the e-Power hybrid powertrain is not only unique but also efficient and effective, especially in our market where EV charging infrastructure is not where it should be. So, if you want to experience an electric vehicle without having to worry about where to charge it, a Nissan Kicks e-Power may just be what you want.

By Gokul Kandiah