The third of Audi’s ‘sphere’ concept cars showing its idea of premium electric vehicles in future in three different segments has been unveiled today: the Audi urbansphere. Where the 2021 skysphere was a roadster GT concept and the grandsphere that followed was a luxury sedan, the urbansphere takes the form of an MPV.

‘Co-created’ with Chinese customers

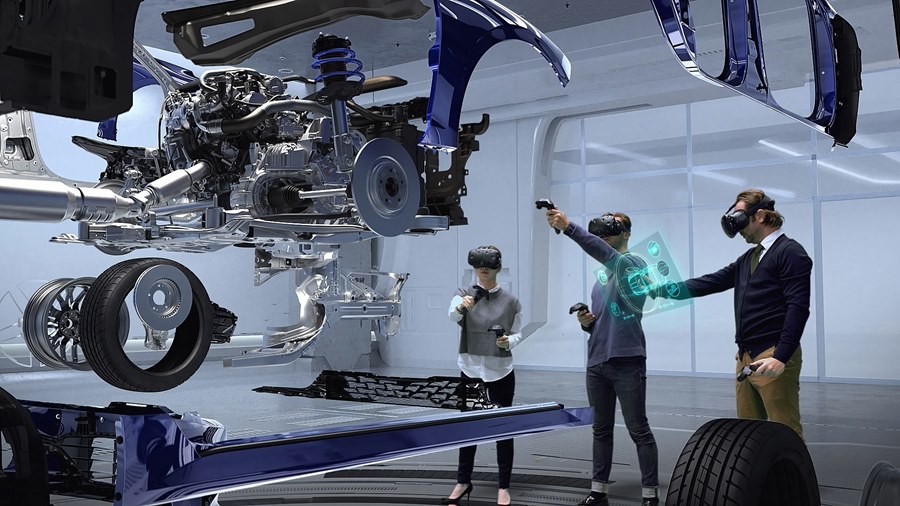

Designed by teams in China and Germany, the urbansphere has been conceived with Chinese customers involvement as well. For the first time, potential customers in China could also take part in the development process, contributing their own perspectives as part of a process known as ‘co-creation’. “In order to meet the demands of our Chinese customers, Audi’s design studios in Beijing and Ingolstadt worked together closely to jointly develop the Audi urbansphere concept car,” said Markus Duesmann, Chairman of the Audi Board of Management and responsible for the Chinese market.

It is the largest model in the sphere family and even of all Audi concept cars to date, measuring 5510 mm in length, 2010 mm in width and 1780 mm tall. The silhouette of the body features traditional Audi shapes and elements, combined to create a new composition featuring the signature Singleframe. The implied wedge shape of the vehicle body is emphasized by the large, flat windscreen.

At the front, the Audi Singleframe is shaped like a large octagon. Even though the grille has lost its original function as an air intake because this is an electric vehicle, it still remains prominent as an unmistakable signature of the brand. The digital light surface lies behind a slightly tinted, transparent visor that covers a large area of the front.

The 3-dimensional light structure itself is arranged in dynamically condensed pixel areas. The upper and lower edges of the Singleframe are still made of aluminium and the vertical connections are formed by LEDs as part of the light surface. The lighting units to the right and left of the Singleframe look narrow, like focused eyes.

These digital lighting units, known as ‘Audi Eyes’, echo the brand’s four rings as they enlarge and isolate the intersection of two rings to form a pupil – a new, unmistakable digital light signature. The illuminated surfaces – and therefore the expression of the ‘eyes’ – can be adapted to the traffic situation, environment, or even the mood of the passengers. As a daytime running light, the gaze can be focused or open, and the ‘iris’ can be narrow or wide. A digitally created ‘eyebrow’ also functions as a dynamic turn signal when required.

MPV of the future?

Though it may be considered an MPV by today’s definition, Audi feels that the urbansphere defies classification into conventional vehicle categories. The monolithic design shares commonalities with the other two concept cars, as do the sculpted, soft shape of the wheelarches. Despite the stately proportions, elegance, dynamism, and an organic design language should come to mind.

‘Third living space’

The 3.4-metre long wheelbase allows a spacious interior designed as a lounge on wheels, serving as a third living space during the time spent on the roads of densely populated cities like Beijing. It can also have a role as a mobile office in which occupants can have meetings or work while moving around. Four individual seats in two rows offer first-class comfort and the seating can also cater to passengers’ changing social needs in a variety of ways.

The interior of the urbansphere is not subject to the dimensional constraints nor limited by the physics of driving. The interior designers had what is the largest interior space in an Audi vehicle to date to prioritize occupant comfort. To this end, it can be a mobile interactive space that provides a gateway to a wider digital ecosystem.

“To make e-mobility even more attractive, we think about it holistically and from the customer’s needs,” said Duesmann. “More than ever before, it is not just the product that is decisive, but the entire ecosystem. That is why Audi is creating a comprehensive ecosystem with services for the entire car. The Audi urbansphere concept offers everyone onboard a wide range of options to use that freedom to provide a highly-personalized in-car experience: communication or relaxation, work or withdrawal into a private sphere as desired. As such, it transforms from being strictly an automobile into an ‘experience device’.“

Customized infotainment offerings are available, such as the seamless integration of onboard music and video streaming services. There is a large-format and transparent OLED screen that pivots vertically from the roof area into the zone between the rows of seats. Using this ‘cinema screen’, which occupies the entire width of the interior, the two passengers in the back row can take part in a video conference together or watch a movie.

Wellness zone, suggested by Chinese customers

The urbansphere also qualifies as a wellness zone, thanks to digital options that emerged in no small part through input from the co-creation process with Chinese customers. Stress detection is a prime example – this adaptive program uses facial scans and voice analysis to determine how passengers are feeling and offers personalized suggestions for relaxation, for example with a meditation app that can be used via the personal screen and the private sound zone in the headrests.

Many of the materials in the interior, such as the hornbeam veneers, come from sustainable sources. This choice of material makes it possible to use wood that has grown close to the site, and the entire trunk can be utilized. No chemicals are used during the manufacturing process.

Audi Light Umbrella

As a special tribute to China, the designers provide a luminous accessory that passengers can take with them when they leave the urbansphere – the Audi Light Umbrella. This self-illuminating umbrella inspired by traditional Chinese umbrellas acts as a protective companion and multifunctional light source. The inner skin is made of reflective material, so the entire surface acts as a glare-free lighting unit.

Because the urbansphere has level 4 autonomous technology which frees its occupants of the need to be directly involved in its operation, it can pick up passengers at their home or office and independently takes care of finding a parking space and charging the battery.

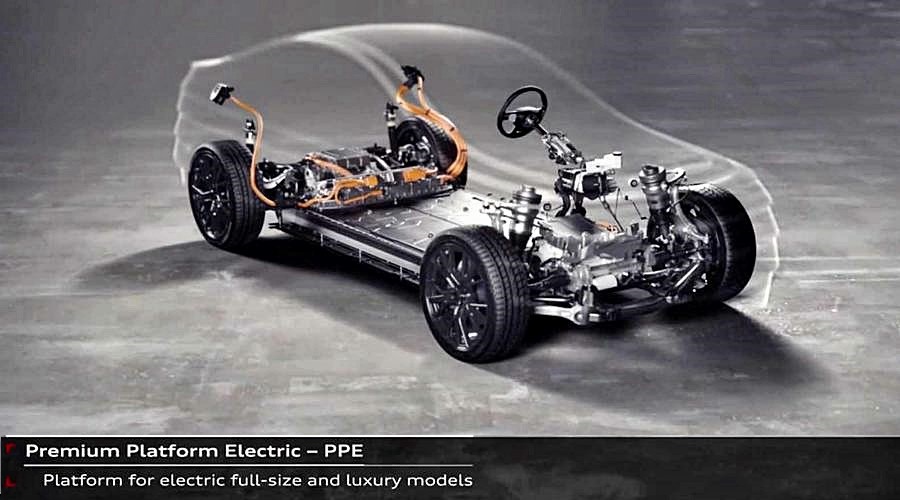

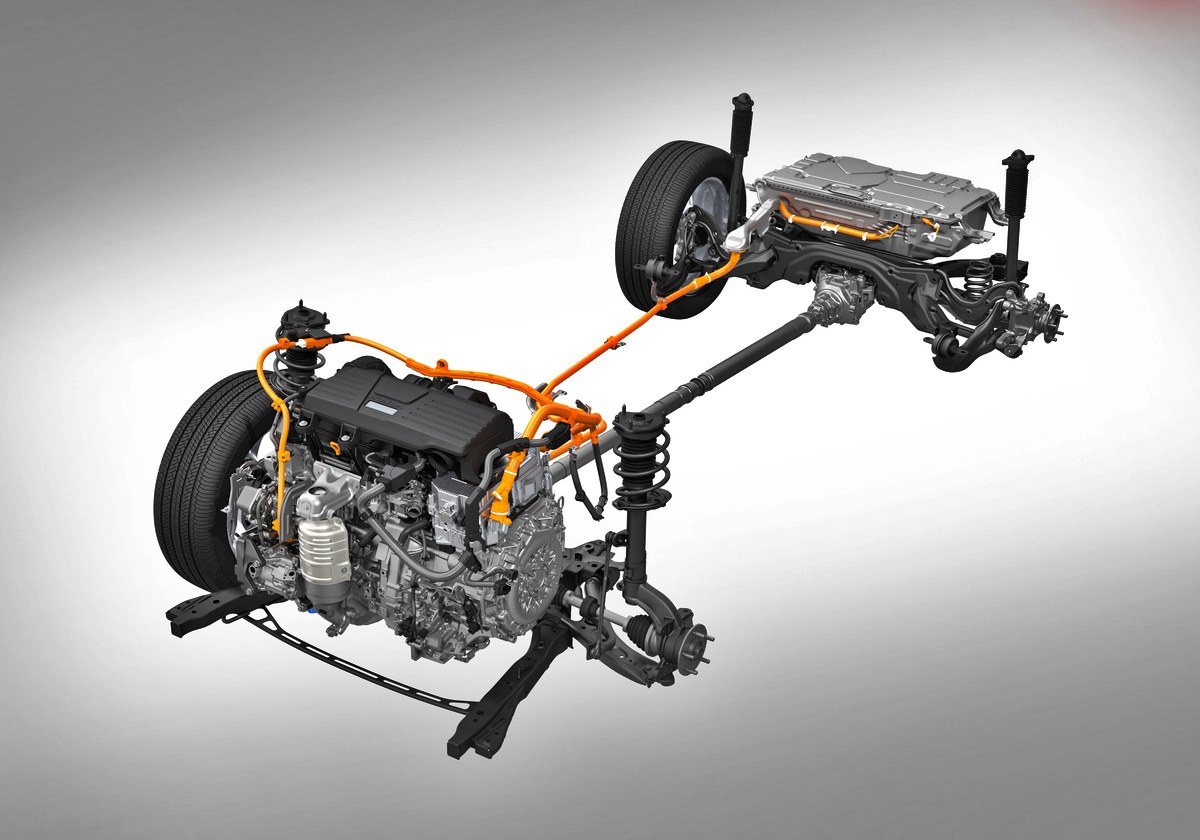

Premium Platform Electric

The urbansphere is a concept and design study so much of what it shows are proposals for the future. However, the Premium Platform Electric or PPE is something that is already in use by Audi and Porsche. It has been specifically designed for battery-electric drive systems and the is a battery module between the axles. Audi has succeeded in achieving a flat layout for the battery module by using almost the entire base of the vehicle between the axles.

The battery module can store around 120 kWh of energy to power 2 electric motors capable of delivering a total system output of 295 kW/690 Nm. There is one electric motor on each of the front and rear axles which, by means of electronic coordination, implements the permanently available all-wheel drive as required. The motor on the front axle can be deactivated as required in order to reduce friction and thus energy consumption when coasting.

The powertrain has 800V charging technology which will make it possible for recharging with up to 270 kW at fast-charging stations in the shortest possible time. This will enable charging times to approach those of a conventional stop to refuel a car powered by a combustion engine. Just 10 minutes would be enough to charge the battery to a level sufficient to cover more than 300 kms. Audi expects that a fully charge battery module would be able to provide a range of up to 750 kms, even when used for more energy-intensive city and short-distance trips.

“These concept vehicles embody our brand strategy. They show how we imagine the near future of premium mobility,” said Henrik Wenders, Senior Vice-President of the Audi brand. For him, the future is a design space to offer people new experiences in ‘spheres’ during their journey.

Audi Charging Hub concept could be refuelling station of the future