In the mid-1960s, when the Malaysian government started the auto industry with a call to manufacturers to assemble vehicles locally, the first ‘auto city’ began to form in the Klang Valley. Vehicle assembly plants were set up in the newly created Shah Alam industrial area of Selangor and related businesses also built factories nearby to supply them parts.

As the industry grew, other areas of the country also saw auto-related factories and businesses being developed. These were in the Tampoi area of Johor and also in Pekan, Pahang, where manufacturers like General Motors, Honda, Mitsubishi Motors, Fiat and Tata had their vehicles assembled.

When the National Car project started in the early 1980s, the Proton factory was situated in Shah Alam, mainly because many suppliers were also in the Klang Valley which also has the largest concentration of new vehicle sales. Perodua, however, chose an area in northern Selangor near Rawang for its manufacturing complex but with the North-South Highway, it had easy connections to the Shah Alam area for suppliers to deliver parts.

By the late 1990s, the auto industry was booming and Proton was seeing rapid growth in volumes that it needed a second factory. Tanjong Malim in Perak was chosen and though far from the Klang Valley, the distance was no longer an issue with the highway connection that also went to Port Klang. DRB-HICOM even made plans to create a ‘Proton City’ which would be an ‘auto city’ like Toyota City in Japan and Detroit in the USA.

However, the late 1990s saw the Asian Financial Crisis seriously affecting the country’s economy and projects like Proton City could not proceed as planned. It had been planned that suppliers would set up factories in the area to support the Proton factory which was designed to produce up to 500,000 vehicles. However, response was poor and with the severe downturn, the idea of Proton City could not take off although Proton began operations at its factory to make a new generation of models.

20 years later, the Proton City idea is restarting although this time, the concept has been updated to take into account changes in the auto industry. Rather than being just a ‘Proton City’, DRB-HICOM will develop the Tanjong Malim area into an Automotive Hi-Tech Valley (AHTV) with the aim of becoming an industry hub for the ASEAN region.

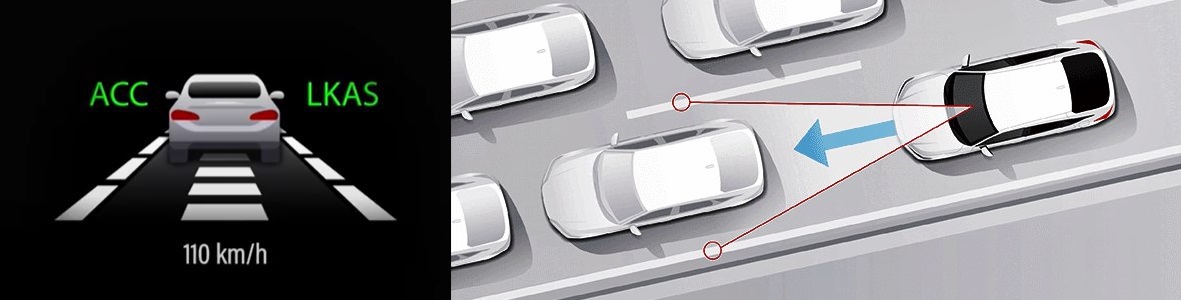

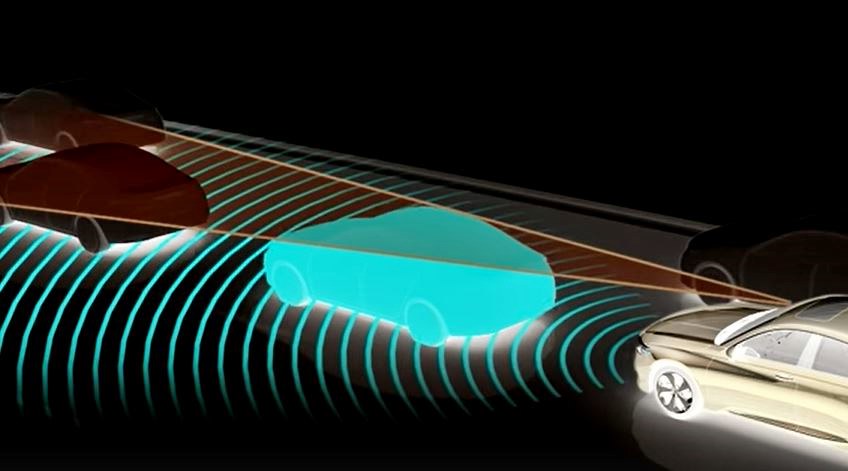

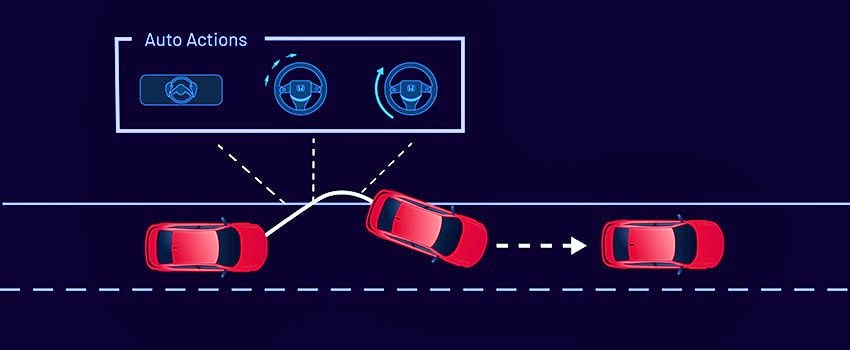

Besides supporting Proton, the AHTV is expected to attract businesses which are involved in new technologies and systems relevant to the global automotive industry. These would include electrification, Artificial Intelligence, autonomous technologies and advanced connectivity.

AHTV will be developed with an integrated ecosystem that will be a catalyst to revitalize domestic automotive sector in line with the direction of the National Automotive Policy 2020. Its aim is to bring Malaysia’s automotive industry to be on par, if not more advanced, than those in neighboring countries.

Perhaps it could help make Malaysia once again the best place in ASEAN to manufacture motor vehicles, which was the case in the 1970s. Back then, this country had the best infrastructure, a growing economy, well educated workforce and a level playing field which was attractive to investors.

An early supporter of the AHTV is the Geely Holding Group, which is also DRB-HICOM’s partner in Proton. The Chinese company has signed an MOU (Memorandum of Understanding) to jointly develop AHTV and collaborate to identify vendors and investors to the hub. The involvement of Geely, which has rapidly become a diverse global automotive group, will bring their technological strength in the automotive ecosystem as a boost for AHTV. This can be an impetus for auto and component manufacturers, especially from China, to invest in local production facilities, to create new business and export opportunities. Essentially, AHTV has the potential to become a gateway to ASEAN and other markets for companies that make it as their base. To date, there are already 17 vendors with facilities within the area.

DRB-HICOM has also signed another MoU with the Perak state government to jointly identify suitable additional land in the area for AHTV development. The current area surrounding the Proton factory measures 4,000 acres, with most already occupied by University Pendidikan Sultan Idris, factories of existing vendors, commercial premises and residential properties.

To boost the automotive talent pool in Malaysia, AHTV will establish a research university. This will create an educational framework to nurture a new generation of engineers for the automotive industry in areas of Engineering, IT, Design, Artificial Intelligence, Mobility Solutions & Software Development. This will strengthen local R&D capabilities and ensure competitiveness of local original equipment manufacturers.

The scale of the AHTV will see some 370,000 job opportunities being created in the area, with more than 160,000 opportunities during the first phase of development.

Proton constructing additional stamping facility at Tanjung Malim factory