electric exhaust gas turbochargerThe trend of downsizing engines which has been going on for the past 20 years has been apparent in all segments and even sportscars now see engines with smaller displacements, but still able to generate high outputs to maintain high performance. New technologies have helped in this respect, and for companies like Mercedes-AMG, technologies developed for Formula 1 cars are being adapted for road cars.

This is the case with the SL 43, a new entry-level version of the roadster range. In the 70 years of its development history, the SL has evolved from a thoroughbred racing car to an open-top luxury sportscar – and it has typically had large and powerful engines. For this new model, there is a 2-litre 4-cylinder engine which may depart from the norm of V8s but is not new to the SL either. In the 1950s and 1960s, there were also SL models with 1.9-litre engines with 4 cylinders too.

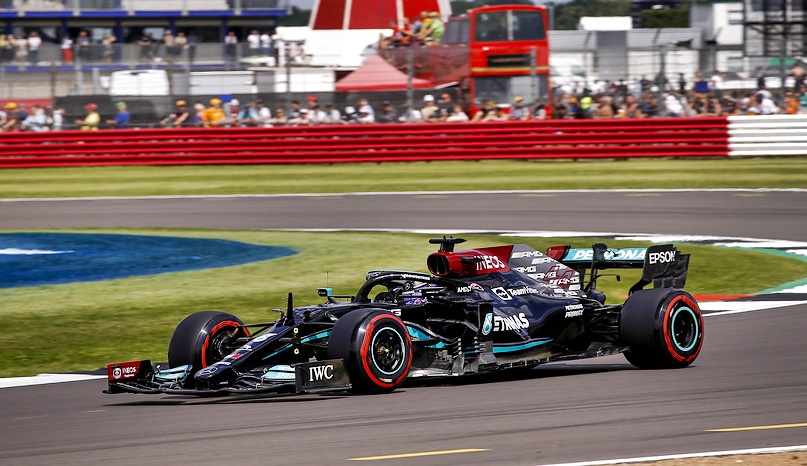

The 2-litre engine in the new SL 43 is a M139 unit and lays claim to being the first in the world with an electric exhaust gas turbocharger for a production model. This technology comes from Formula 1, having been used in the multiple championship-winning racing cars of the Mercedes-AMG Petronas F1 Team for many years.

Electric exhaust gas turbocharger

The electric exhaust gas turbocharger employs an electric motor around 4 cm thin integrated directly on the turbocharger shaft between the turbine wheel on the exhaust side and the compressor wheel on the intake side. Electronically controlled, this drives the shaft of the turbocharger directly and thus accelerates the compressor wheel before the exhaust gas stream starts to drive it conventionally. It works at speeds of up to 170,000 rpm, which enables a very high airflow rate.

The advantage of having this little motor is significantly improved and immediate response from idle and across the entire engine speed range. The combustion engine (similar to the ones used in models like the C-Class) responds even more spontaneously to accelerator pedal input, while the electrification of the turbocharger enables higher torque at low revs. Even when the driver takes their foot off the accelerator or applies the brakes, the technology of the electric turbocharger is able to maintain the boost pressure at all times enhancing response.

The motor, powered via the 48V on-board electrical system, along with the turbocharger and power electronics are connected to the engine’s cooling circuit to ensure an optimal temperature environment at all times. Maximum output is 381 bhp at 6,750 rpm, with 480 Nm of torque available between 3,250 rpm and 5,000 rpm. Depending on the situation, the system can also provide a boost of 14 bhp briefly from the belt-driven starter generator (RSG). The second-generation RSG, in addition to the temporary power boost. enables functions such as gliding mode and energy recovery for greater efficiency.

AMG SPEEDSHIFT MCT 9G transmission

Drive to the rear wheels is through the AMG SPEEDSHIFT MCT 9G transmission (MCT = Multi-Clutch Transmission) which is used for the first time. A wet start-off clutch replaces the torque converter, its advantage being reduced weight and, thanks to its lower inertia, optimised response to accelerator pedal input, especially during spurts and load changes. There is also the RACE START function for quicker departures from standstill.

Performance claims show that this entry-level version is no less worthy of the SL badge, wit its ability to go from 0 to 100 km/h in 4.9 seconds and reach a top speed of 275 km/h. Fuel consumption, depending on the driver’s behaviour, can be up to 11.2 kms/litre, it is claimed.

Aluminium composite structure

The latest R232 series SL has a completely new architecture developed by Mercedes‑AMG. The new dimensional concept allows a 2+2 seating configuration for the first time since 1989. Constructed from lightweight aluminium composite, the chassis consists of an aluminium space frame with a self-supporting structure for maximum rigidity. The bodyshell architecture focusses on lateral and longitudinal dynamics while offering comfort and ensuring safety.

In the new SL, the intelligent material mix enables the highest possible rigidity at a low weight. The materials used include aluminium, magnesium, fibre composites and steel, from which the windscreen frame is made, for example. This serves as roll-over protection in conjunction with the roll-bar system behind the rear seats which pops up at lightning speed when needed.

Entry-level model features

While the overall form and SL proportions are similar, the exterior of the SL 43 has some details which differ from the two 8-cylinder models. For example, it has differentiated front and rear aprons as well as round instead of angular double tailpipe trim. 19-inch light-alloy wheels as standard but customers can also opt for aerodynamically optimised light-alloy wheels with diameters of 20 or 21 inches. The 20-inch wheels come with plastic aero rings that save additional weight.

Active aerodynamics

A technical highlight for improving aerodynamics is the AIRPANEL active air control system. The horizontal louvres behind the upper air intake are electronically controlled and can be opened and closed with actuator motors. In this way, the airflow is directed according to demand, thus improving aerodynamic performance.

Normally the louvres are closed to reduce air resistance. Should certain operating temperature levels be exceeded, the louvres will open and allow cooling air to flow to the heat exchangers. This calls for highly intelligent and fast control. When the temperature drops below the defined level, the louvres will automatically close again.

The same applies to another active aerodynamic component – the retractable rear spoiler integrated into the car’s profile. It changes its position depending on driving conditions. Numerous parameters are considered to determine the position – driving speed, the longitudinal and lateral acceleration and steering speed are among the factors. The spoiler can assume 5 different angles when speeds are more than 80 km/h to either optimise handling stability or reduce drag.

Lightweight fabric soft top

The latest SL uses a soft top instead of the previous metal vario-roof, removing 21 kgs of weight. The Z-fold saves space and weight, and makes it possible to dispense with a conventional soft-top compartment cover. For convenience, an electric motor opens and closes (at speeds up to 60 km/h) the soft top within 15 seconds. Switching to a soft top also lowers the centre of gravity, benefitting driving dynamics and handling.

‘Hyperanalogue’ cockpit

The interior of the SL 43 has a combination of analogue geometry and the digital world which the designers refer to as ‘hyperanalogue’. This is exemplified by the fully digital instrument cluster which is integrated into a three-dimensional visor. The symmetrical instrument panel is designed as a powerful wing and structured into an upper and lower section. The highlight on the dashboard are the 4 galvanised turbine nozzles which surfaces merge into the instrument panel in the form of powerful power domes. Despite symmetry, the cockpit design creates a clear focus on the driver.

“In its long history, the SL has repeatedly set technological milestones. For example, while the legendary 300 SL Gullwing in 1954 was the world’s first series-produced passenger car with direct petrol injection, the new Mercedes-AMG SL 43 is now the very first series-produced vehicle with an electric exhaust gas turbocharger. With this technology, the SL also has an outstanding performance range in its entry-level version. This means that our seemingly smallest SL combines the typical AMG Driving Performance with luxury and comfort at the absolute top level. What’s more, with this innovative engine we are undoubtedly also appealing to a wider clientele,” said Philipp Schiemer, Chairman of the Board of Management of Mercedes‑AMG GmbH.

Virgil Abloh may not be a familiar name to many, but he was a collaborator with Mercedes-Benz on various design studies, particularly related to luxury products. Abloh, who passed away last year, was an artist, architect, engineer, creative director, artistic director, industrial designer, fashion designer, musician, DJ and philanthropist. As such, his visions and ideas were of much interest to Gorden Wagener, Mercedes‑Benz Group AG Chief Design Officer.

Together, they worked on projects such as Project Gelandewagen and Project MAYBACH and now, Abloh’s cooperation with Mercedes–Maybach culminates in the launch of a limited-edition bespoke S-Class and capsule collection, inspired by Project MAYBACH. It’s the final chapter of Project MAYBACH and is available in a strictly limited run of 150 units.

The launch coincides with the release of a capsule collection designed by Abloh and in collaboration with Off‑White. It has been developed in connection to the Project MAYBACH electric showcar and is exclusively available to buy on Off‑White, Farfetch and Maybach Icons of Luxury online stores, as well as Off‑White stores in select markets.

The limited edition Maybach by Virgil Abloh is a fully equipped Mercedes‑Maybach S‑Class S680 which follows the tradition of the ultra-luxury brand that has a history of over a century. It has been created by Mercedes‑Benz’ most specialised customization and craftmanship team. The exterior features the unique two-tone colour combination created for Project MAYBACH, with the upper part lacquered in a glossy obsidian black and the lower part, side flanks and special forged rims painted in a sand hue.

Superlative levels of craftsmanship will be evident throughout the cabin which has an identical two-tone colour scheme. The 4-seat configuration, steering wheel, doors, lower dashboard and ceiling are lined in black and sand-coloured nappa leather, complete with sand-coloured decor trims and strips. The highpile floormats are black with a sand-coloured leather border and embroidered Mercedes‑Maybach logo.

To enhance its monolithic appearance, the window frames are painted, and a special Mercedes-Maybach and Virgil Abloh logo is inscribed on the piano black middle of the centre console, rear cushions, head restraints and door sill panel.

Unique to the limited-edition S‑Class is a bespoke user interface which presents the driver with an even more luxurious variation of the Maybach MBUX suite of cutting-edge technologies. Han picked visual elements are used to enrich the digital content. For example, the home button has a coloured border and brand logo denoting the edition, and profile pictures are decorated with luxurious fashion accessories.

All customers will be given a special custom-made wooden box covered in sand-coloured nappa leather emblazoned with the Mercedes‑Maybach and Virgil Abloh logo. The gift box contains a 1/18 scale replica of the limited-edition car, the two car keys and a carabiner hook. In addition, each car will come with a complimentary and exclusive car cover featuring the Mercedes‑Maybach and Virgil Abloh logo.

“I’m incredibly proud of the work we have created in collaboration with Virgil. From Project Gelandewagen, which set the benchmark for fashion/automotive collaborations with our iconic G‑Class, to Project MAYBACH which brought the distinguished Mercedes‑Maybach heritage into the future, together with Virgil, we truly broke new ground. The limited edition Maybach by Virgil Abloh exemplifies the symbiosis between innovative design and ultimate craftsmanship now available on the road,” said Wagener.

New generation of Mercedes-Maybach S-Class arrives in Malaysia, priced from RM1.9 million

Honda Malaysia has announced the appointment of Hironobu Yoshimura as its new Managing Director & CEO. He takes over from Madoka Chujo who has returned to Honda’s head office in Japan to assume a new role in the Automobile Operations Sales Supervisory Unit, Sales Division which covers a larger number of markets.

Mr. Yoshimura has been with Honda Motor for 34 years, with experience in the areas of Corporate Planning, Business Planning, Marketing and Aftersales Services. He has held key roles in various countries such as Japan, Thailand and Pakistan, with his position prior to coming to Malaysia was being President & CEO of Honda Atlas Cars (Pakistan) Limited.

“I am excited to take up this new role at Honda Malaysia. This unique and diverse nation is truly an important market in the Asia and Oceania region for us at Honda. My predecessors have built the Honda brand to become the success that it is now in Malaysia – as the forerunner in introducing Honda’s advanced technology in the region, launching exciting new models and leading the Non-National Passenger Vehicle segment for many years,” he said.

“Most importantly, Honda Malaysia has persevered through and overcame many challenges over the years. I look forward to leading the company in a post-pandemic business environment and to contribute positively towards the growth of the company,” he added. “I am also pleased to share that based on our internal data, three Honda models have ranked No.1 in their respective segments for the first quarter of 2022. The models are the City, City Hatchback and the latest Civic.”

During her short time in Malaysia, Ms. Chujo led the company through a difficult period when the country was still having restrictions due to the COVID-19 pandemic. Nevertheless, she introduced the new City Hatchback and Civic models as well as celebrated the production of the 1-millionth vehicle at the Honda Malaysia plant in Melaka recently. During her term, Honda Malaysia also maintained its No. 1 position in the Non-National Passenger Vehicle Segment for the 8th consecutive year.

Honda Malaysia’s local vehicle assembly crosses 1 million mark

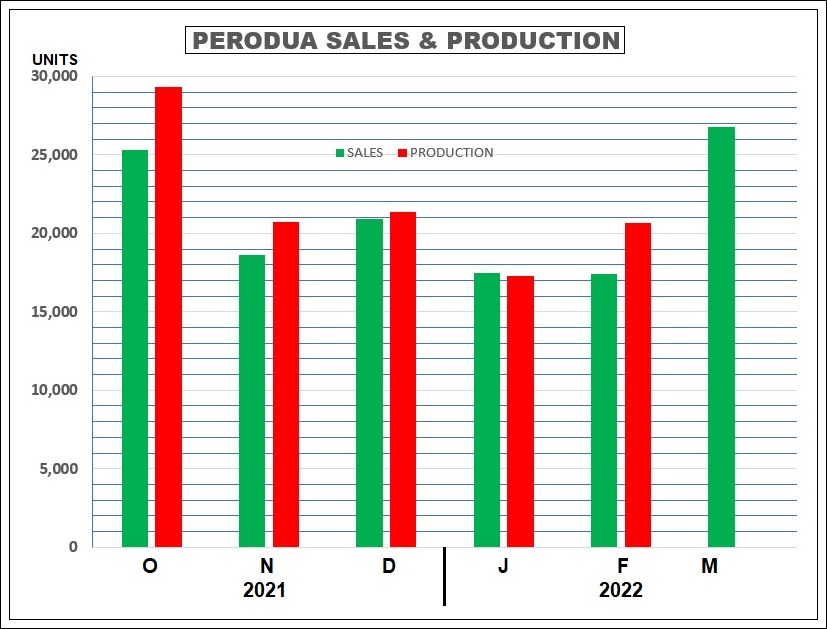

In spite of the challenging conditions during the first quarter of 2022, some of which were carried over from the floods of December 2021, Perodua was able to steadily build up its volume again over the three months.

The Malaysian carmaker reports that it ended the quarter with 61,624 vehicles delivered to customers nationwide. This was an increase of 6.4% compared to the same period in 2021.

On a month-on-month comparison, 26,759 vehicles were delivered in March 2022, a 9.5% increase from the 24,433 units reported in March 2021. Its February sales volume was 17,421 units, almost the same as in January, with the two months being unusually low as the carmaker’s production was affected by parts supply issues.

According to Perodua’s President & CEO, Dato’ Zainal Abidin Ahmad, the impact of COVID-19 and component supply issues are still present. However, the company has been able to work with its suppliers and dealers to lessen their impact.

“Our focus is now to expedite the vehicles delivery to our customers before the sales tax exemption deadline ends on June 30, 2022. That being said, Perodua also echoes the Malaysian Automotive Association’s request to further extend the sales tax exemption as factors such as the global semiconductor supply disruption and COVID-19 cases are still impacting the industry,” he added.

Dato’ Zainal said that the automotive industry, including its local ecosystem, thanks the government for the initiative (in the form of the sales tax exemption) as it was able to keep demand high and sustain the industry throughout the worst of the pandemic.

“Right now, the local automotive ecosystem is starting to recover and an extension in the sales tax exemption is what the industry needs for sustained growth during this recovery period,” he said.

“Moving forward, we foresee the second quarter of 2022 to be the highlight for the automotive industry as brands will deliver as many vehicles as they can within that 3-month period. While semiconductor chip supply and COVID-19 would still influence production, we expect that production and registration will continue to improve,” said Dato’ Zainal

He added that the company does not foresee other factors such as the conflict between Russia and Ukraine to have a major impact on the company’s production moving forward. Based on these factors, Perodua is maintaining its 247,000 sales target for 2022.

For decades, car designers have been inspired by fighter jets, with American designers being so infatuated with the tailfins and jet engines that they put them on cars of the 1950s. In the decades that followed and even up till today, the inspiration from flying machines remains and it’s not only with the exotic and sleek supercars. This was evident when, back in 2005, a young Proton designer said that the Savvy’s design also had some inspiration from the F-117 Nighthawk stealth fighter.

At Lamborghini, the designers would of course have been much influenced by jet fighters and the highly aerodynamic shapes make this obvious. The Reventon, which was unveiled 15 years ago, was a clear example of such influence and Lamborghini even mentioned the aircraft that was the source of inspiration: the McDonnell Douglas F-15 Eagle. Many also saw elements of the F-117 with the sharp and angular form, especially with the dark finish.

20 units for sale

The Reventon, displayed at the 2007 Frankfurt Motor Show, appeared like a one-off concept with an extreme design but it was to be an exclusive model built for sale to 20 customers. The ex-factory price then was quoted as 1 million euros, which made it the most expensive Lamborghini up till that time.

The supercar was based on the Murcielago LP640 and had similar proportions as the Gallardo as well. It was not so obvious then but much of the design language used for the car would later appear in the Aventador as well.

“The Reventon is the most extreme of all, a true automotive superlative. Our designers at the Lamborghini Style Centre took the technical base of the Murcielago LP640 and compressed and intensified its DNA, its genetic code,” said Stephan Winkelmann, President & CEO of Lamborghini then (and still in the same position today).

Lamborghini’s naming tradition

Keeping to Lamborghini tradition, the name was that of a fighting bull, owned by the Don Rodriguez family. It is included in the list of the most famous bulls ever and is known for killing the famed bullfighter Felix Guzman in 1943.

Like today’s Lamborghini models, the edges of the body are sharp, with precise lines and clean surfaces – these are ingredients of a style reduced to the essential. Each element is created exactly according to its function; ornaments and decorations are totally foreign to a Lamborghini.

With the Reventon, the Centro Stile designers developed this philosophy with an extremely precise, technically striking style that mimicked the fastest fighter jets. The bodyshell was made of a composite carbonfibre material (CFC) and steel, with the exterior components glued and fixed on.

The front was characterized by the acute angle of the central ‘arrow’ and by the powerful forward-facing air intakes. Although they did not supply air directly to the turbine like an airplane, an abundant volume of air was still necessary to cool the carbon brake disks and the 6-cylinder calipers.

From the time of the legendary Countach, Lamborghini’s V12 models have had ‘scissors doors’ which open upwards. With their asymmetric configuration on the Reventon, the large air intakes below the doors provided an example of the extreme coherence with which a Lamborghini fulfils its function. On the driver’s side, it was large to increase the flow of oil to the radiator. On the passenger’s side, the air intake was flat because, in this case, it only had to ensure the flow below the floor.

The aerodynamically optimised flat floor structure terminated at the rear with a diffuser featuring an accentuated shape. This guaranteed superior road grip and stability even at the 340 km/h the car was capable of. Because of such a high speed, aerodynamics had to be optimized. The airflow and the section of the variable geometry air intakes of the engine and the rear spoiler (adjustable) were specially shaped and designed after lengthy wind tunnel studies.

The engine was the classic 12-cylinder unit with a 6.5-litre displacement and tuned to produce 650 bhp/660 Nm. For super-fast and precise shifting, there was a robotised e.gear system with a permanent Viscous Traction 4-wheel drive system to get all that power to the road.

The engine cover was made of glass laminate with open ventilation slits that offered a glimpse of the 12 cylinders within. The glass also featured the marked arrow angle that characterized the design from the front to the rear spoiler.

The Lamborghini designers’ love for detail was illustrated by the fuel tank lid: a small mechanical work of art, achieved by milling a solid aluminium block. The combination lights transformed the incisiveness of the design into light, with the front having LEDs alongside Bi-Xenon headlights. Seven LEDs served as Daytime Running Lights while another nine diodes were used for the indicator and hazard lights. Because of the high temperature in the rear lower section of the car, special heatproof LEDs were used for the indicator and hazard lights, brake lights and rear lights with a triple arrow optical effect.

Aircraft display for driver

The cockpit of the Reventon certainly had a lot of aircraft inspiration, with the instrument panel housing three TFT liquid crystal displays. The instruments were housed in a structure milled from a solid aluminium block, protected by a carbonfibre casing. At the touch of a button, the driver could choose from two vehicle information display modes. Today, with fully graphic and digital displays, a driver can customize the instrumentation even more.

An interesting feature was the g-force meter, something which was novel then but would later appear in some high-performance models. This display showed the dynamic drive forces, longitudinal acceleration during acceleration and braking, as well as transversal acceleration around bends. The forces were represented by the movement of an indicator on a graduated 3D grid depending on the direction and intensity of the acceleration. A similar instrument can be found in aircraft and Formula

It took less than a year for the Reventon project to progress from the first ideas to the finished car. Centro Stile, which was just a few years old then, was able to carry out the entire design process at Lamborghini for the first time without any external collaboration with design studios like Bertone.

The Reventon Roadster

Two years after unveiling the Reventon coupe, Lamborghini showed a roadster version at the 2009 Frankfurt Motor Show. It had a slightly more powerful engine but the top speed was 10 km/h less. Lamborghini offered it for 1.1 million euros but never revealed just how many were sold, although it said that there would be less than 20 units.

The original Reventon production was done between 2007 and 2009 and besides the 20 units that were sold, one more unit was built and is displayed at the Lamborghini Museum of Technologies. Half of the cars made are known to have gone to the USA and the rest went to other countries. The Reventon was one of the first ‘few-offs’ from the brand and remains as one its most iconic models too.

Lamborghini Countach in ‘The Cannonball Run’ listed in US National Historic Vehicle Register

© Copyright – Piston.my 2024 Trademarks belong to their respective owners. All rights reserved