Following its appearance at the 2025 Bangkok International Motor Show, the Geely Xingyuan—also known under the Geome sub-brand—has made its way to China’s premier automotive event, Auto Shanghai 2025. Displayed alongside Geely’s high-tech Galaxy Cruiser SUV prototype, the compact electric vehicle (EV) has reignited speculation about its potential rebadging and entry into the Malaysian market under the Proton badge as the e.MAS 5.

If confirmed, the Xingyuan would become the second model in Proton’s e.MAS series, complementing the larger e.MAS 7 that has already been introduced in Malaysia. While official announcements remain pending, industry watchers note that the Xingyuan’s compact dimensions and urban-friendly electric powertrain make it an ideal fit for markets such as Malaysia, where demand for affordable, efficient electric mobility is growing.

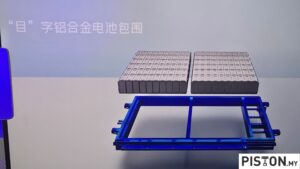

In China, the Xingyuan is offered with two electric powertrains, both using lithium iron phosphate (LFP) batteries supplied by CATL. Fast-charging capabilities allow for a 30% to 80% charge in just 21 minutes. The entry-level variant comes equipped with a 30.12 kWh battery, offering a range of 310km under the Chinese Light-Duty Vehicle Test Cycle (CLTC), and is paired with a rear-mounted motor delivering 79PS and 130Nm of torque. The higher-end model features a larger 40.16 kWh battery that stretches the range to 410km, along with a more powerful 116PS, 150Nm electric motor. Both versions include a deep front trunk—or ‘frunk’—enhancing cargo versatility.

Five variants are currently offered in the Chinese domestic market. Standard and optional features include 16-inch alloy wheels, full LED lighting, a large 14.6-inch infotainment touchscreen (or a smaller 10.1-inch unit in base trims), 256-colour ambient lighting, either a four- or six-speaker audio system, and an external 3.3 kW power outlet for accessory charging. Comfort and convenience features span from manual to powered front seats, automatic air conditioning with rear vents, an 8.8-inch digital instrument cluster, and a 50W wireless phone charger with air-cooling. Comprehensive advanced driver assistance systems (ADAS) are also available, underlining the model’s emphasis on safety and smart technology.

Sized for the urban commuter, the Xingyuan is noticeably more compact than its e.MAS 7 sibling. It measures 4,135 mm in length and 1,805 mm in width, with a wheelbase of 2,650 mm—figures that position it firmly in the B-segment crossover category.

With growing anticipation surrounding its potential localisation, the question remains whether this small electric hatch will arrive in Malaysia bearing the Proton badge.