When ‘Volvo’ is mentioned, many models come to mind and it depends on which generation is responding. Older people will think of the 122 Amazon and 244 while a generation later would remember the 850R. But everyone is likely to remember the P1800, perhaps Volvo’s most internationally renowned model ever and the one that arouses most emotions.

Planned in Sweden, designed in Italy, unveiled at a car show in Brussels, built in Britain and a huge success in the USA, production of the P1800 took place between 1961 and 1972. It had reached showrooms after 4 years of careful planning and development and while sales numbers were not spectacular, the image viewpoint it played was far bigger role than any previous Volvo model.

A ‘halo model’

The Volvo P1800 was born for that very reason – to attract the attention of passers-by to Volvo’s showrooms and to increase what today is known as ‘floor traffic’. Once ‘captured’, it was up to the sales advisors to do whatever they could so that people who entered the showroom left it after placing an order for a new Volvo.

The P1800 wasn’t Volvo’s first go at making a sportscar. Back in the early 1950s, it had produced the open 2-seater plastic-bodied Volvo Sport between 1955 and 1957. Only 67 cars were ever made and the production ended rather abruptly because the company’s President then, Gunnar Engellau, was disappointed with the quality. “Not a bad car… but a bad Volvo” was the way he put it when he gave the order to stop production.

However, he recognised the importance of having a prestigious and exciting model to boost overall sales, and Volvo dealers were desperate for just such a car. This led to another go at making a sportscar and design proposals were ordered from Italy. Volvo consultant Helmer Petterson – who was deeply involved in the planning of the new car – had got his son, Pelle, a job at Pietro Frua, thanks to Pelle’s fresh degree in industrial design from the Pratt Institute in New York.

Designed in Italy… by a Swede

When the time came to unveil the 4 proposals to Volvo’s board members in 1957, Helmer sneaked in his son’s design as a fifth possibility – and that was the one that everyone picked! Engellau, in particular, liked it since he had very definite views about wanting an Italian-designed car. That of course is precisely what he did get – except that it was actually the work of a 25-year old native of Goteborg, Volvo’s home city!

Eventually, however, the truth behind the winning design proposal emerged. Engellau was furious as he felt he had been tricked and promised that Pelle would never be acknowledged as the car’s designer. And indeed, many years went by before the truth was made known and Pelle Petterson received the credit he was due for designing one of the world’s most attractive sports coupes.

The new sportscar had a fixed roof, steel body, with a lot of the mechanical components taken straight from the 122 Amazon. It was powered by the newly developed B18 engine in its 100 bhp sports version when it eventually arrived in the showrooms.

Initially made overseas

At this time, Volvo found itself in a hugely expansive phase and the company realized from the outset that it did not have sufficient in-house capacity to manufacture the new model – not for pressing of body panels, nor for painting or assembly, not even on a small scale. The hunt for a suitable partner got under way and after much deliberation, a decision was taken to use two British companies to build the car: Pressed Steel would build the bodies and Jensen Motors would paint and assemble the cars.

Production started but this was a far from friction-free method. Constant problems with personnel, working methods, quality, suppliers and logistics along with an unwillingness to deal with these issues meant that as soon as it was possible, Volvo transferred production home to Sweden.

By early 1963 – after Jensen had completed 6,000 cars – production of the 1800 started up in Volvo’s Lundby factory. But it was not until 1969 that body pressings were transferred from Pressed Steel in Scotland to Volvo’s own press shop in Olofstrom. The move home also coincided with a change of name for the P1800. At first, it was badged the ‘P1800 S’; later in 1963, it was known simply as the ‘1800 S’, the alphabet standing for Sweden.

During the car’s long life, no radical changes were made to the successful exterior lines. Only details such as the grille, trim mouldings, wheels and colours differentiate the various model years. From the technical viewpoint, the 1800 shadowed the development of Volvo’s other models and was continuously upgraded. Disc brakes all round, more powerful engines and electronic fuel injection were the most noticeable changes.

During its production life, two other body variants were also available. One was a convertible (only 30 units) and the other was the 1800 ES, with an extended roofline and an estate car rear featuring a large glass tailgate. The variants were designed in in-house this time and attracted considerable attention too.

Becoming The Saint’s car

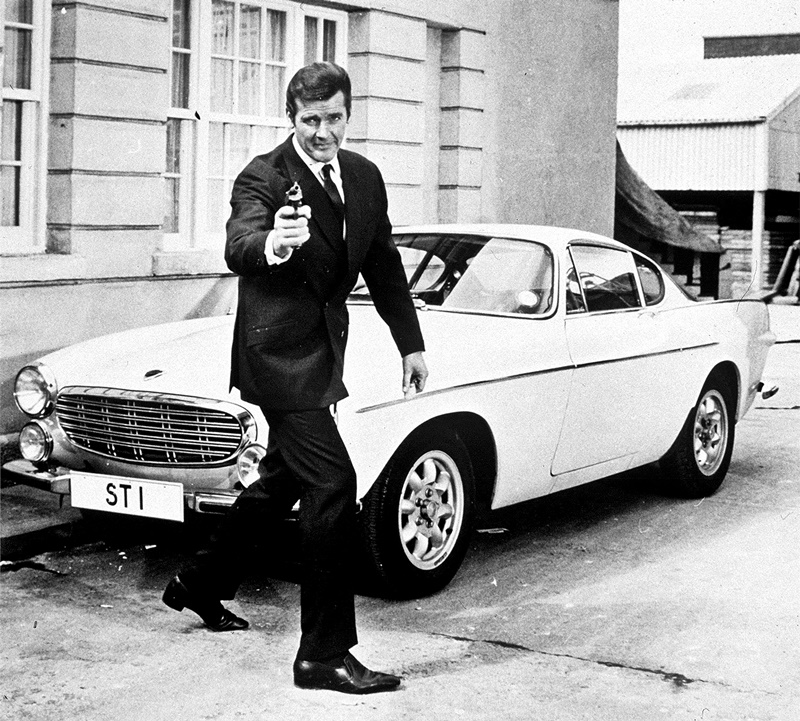

Roger Moore was fortunate enough to drive a P1800 in his role as crime-fighter Simon Templar in the British TV series, ‘The Saint’. The TV production company had been looking for an attractive sportscar that would suit a gentleman of independent means and, after being turned down by Jaguar, approached Volvo to ask for the P1800. Volvo was, of course, quick to oblige as it would be a brilliant PR move for the new model. Every week, it appeared in the living rooms of TV viewers, becoming so firmly etched in minds that it came to be referred to as ‘The Saint’s car’.

The P1800 was never intended to be a mass-produced car. As mentioned earlier, it was planned as a niche product or what is today referred to as a ‘halo model’. Yet it was viable enough to be within the reach of most people who wanted a car that looked like a Ferrari but cost and functioned like a Volvo – pleasant, reliable and economical.

LOOKING BACK: The forgotten Volvo P1900 sportscar with a fibreglass body