In many factories, one of the many practices where employees can be involved in improving processes or quality has been the suggestion system, for which they are rewarded if their ideas are adopted.

Honda also has a program called IGNITION which was started in 2017 by Honda R&D Co., Ltd., its research and development subsidiary. This is a business creation program where Honda employees can propose new business ideas and then implement the technologies, ideas or products to help solve societal problems and create new value for people.

Since being initiated, many applications have been received for new business ideas as well as numerous suggestions that fit with Honda’s business activities and are already being pushed internally towards commercialization.

Bringing new ideas to the market

There have also been proposals with added social value that can be implemented more quickly in the form of a start-up instead of being implemented within the Honda organization. In 2020, IGNITION was therefore expanded to include the option of bringing new business ideas to the market by setting up companies.

Ashirase system for visually impaired

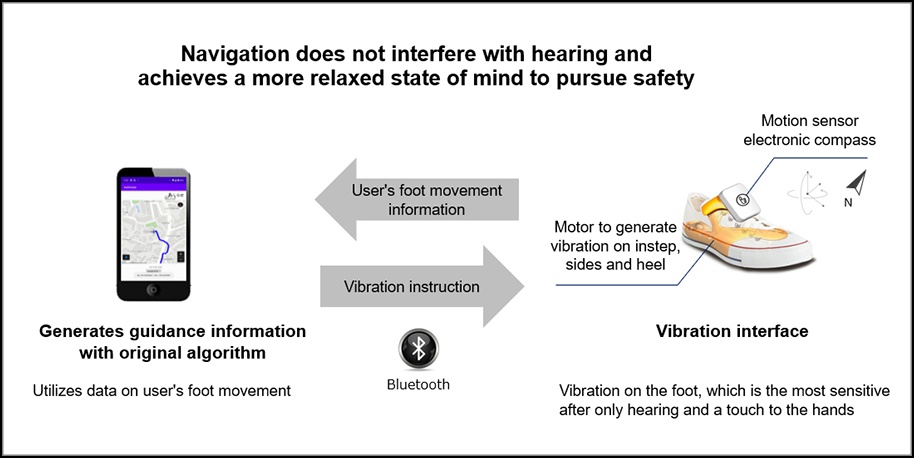

The first company to emerge from the IGNITION program in this way is Ashirase Inc., which will develop an in-shoe navigation system to support the visually impaired while walking. The system, also called ‘Ashirase’, uses a smartphone app and 3-dimensional vibration device including a motion sensor, which is attached inside the shoe.

With the concept of ‘navigation which enables safety and a relaxed state of mind for the visually impaired’, Ashriase is being developed as a product which helps the users reach their destinations safely and have a more independent lifestyle.

The IGNITION program was originally for Honda R&D but is now expanded to the entire company for full-time employees in Japan to drive new business ideas. The ideas will not come from engineers but also of employees from other areas such as production, sales and even administration.

Evaluated from investor’s perspective

IGNITION works with a corporation that, as one of the jurors, evaluates the proposals from the perspective of an investor. In addition, applicants have access to advice and support from the corporation during the assessment process.

The decision on whether to market is made within 6 months and the marketing will be done by Honda itself or through the establishment of a start-up company. In order to preserve the independence of the start-up company, Honda’s equity stake is limited to a maximum of 20%.

“There are many employees at Honda who want to contribute to social development with their technologies and ideas. IGNITION is a program that promotes and develops these ideas and technologies among Honda employees and helps them create new values that contribute to solving societal problems,” explained the Head of the IGNITION Jury and Managing Officer of Honda Motor Co., Ltd., Yasuhide Mizuno (who was a former MD & CEO of Honda Malaysia).

“We are now expanding the program to all employees in Japan and offering them the additional option of starting their own business. The hurdles for starting a business are very high, but we hope that IGNITION will continue to drive the challenging spirit at Honda and enable us to create new products and experiences that go beyond our core business,” said Mr. Mizuno.

Click here for more news and articles about Honda.