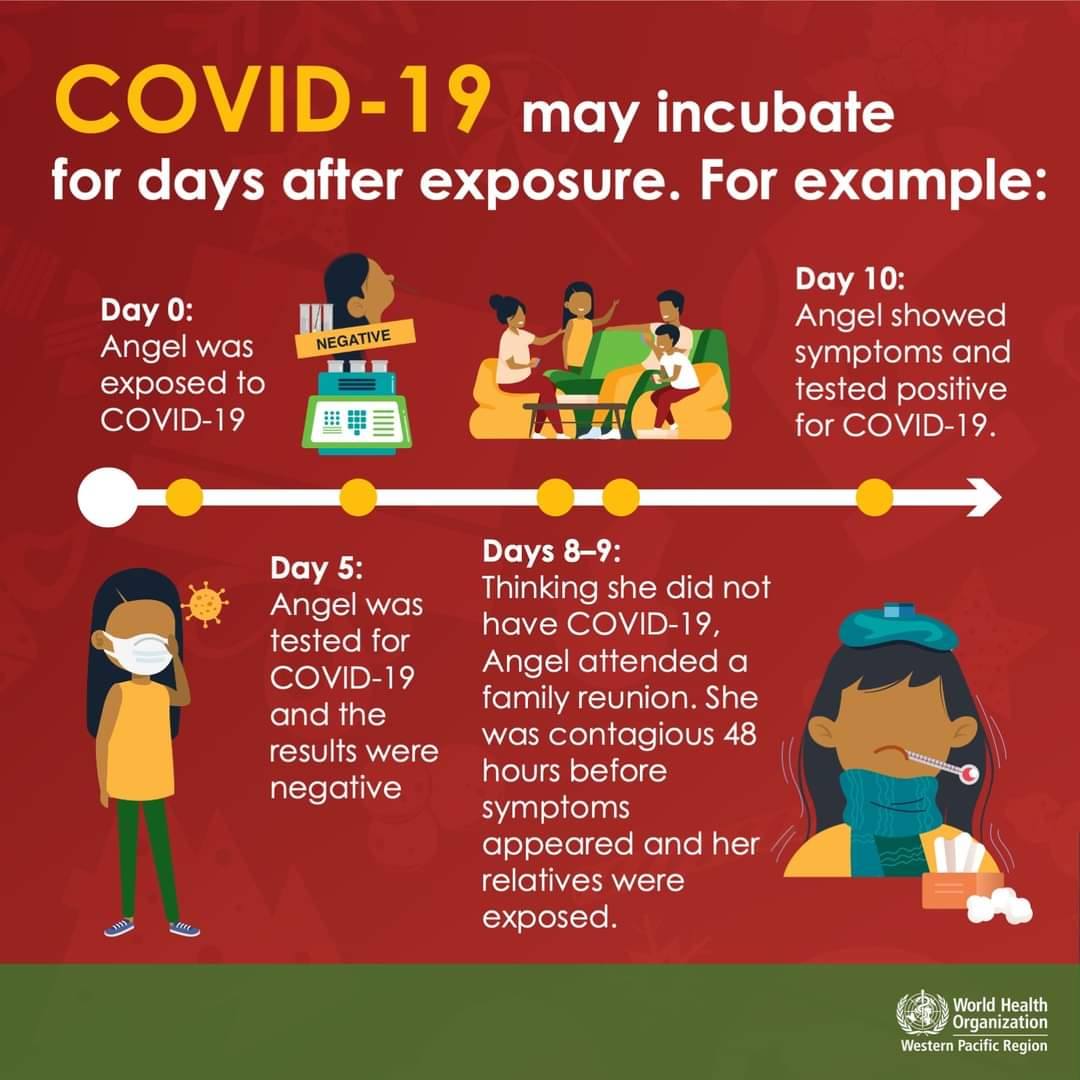

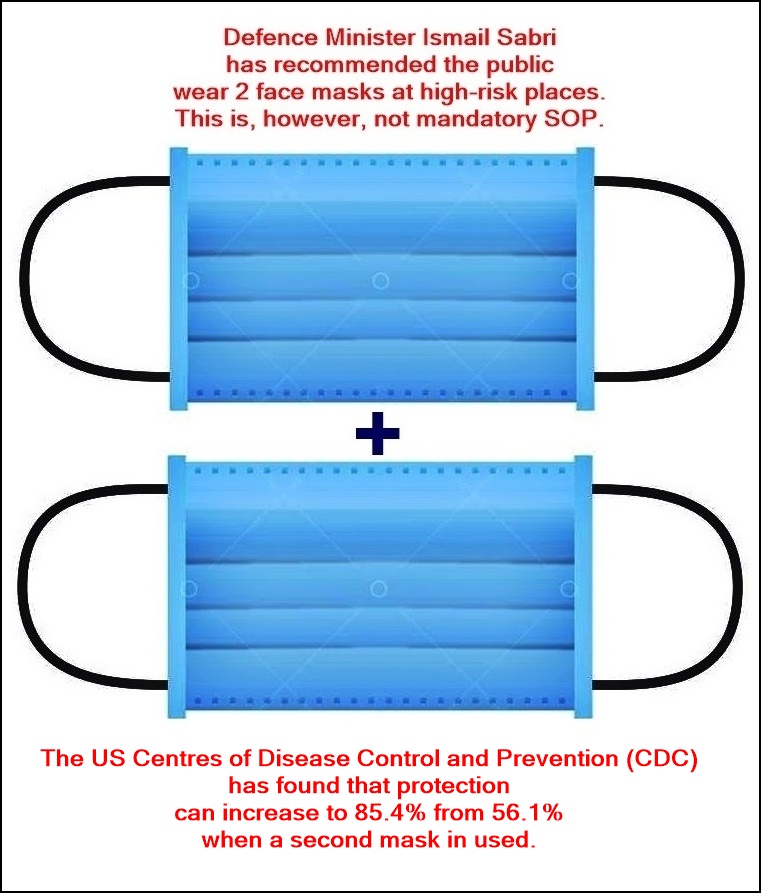

Everyone has to do their part in fighting COVID-19 and the simplest way you can help is to just stay at home for the next two weeks (and it doesn’t cost you money). Businesses too are trying to help, even though many have been affected by the challenging conditions over the past year. But those that can help are doing so and one of them is GoCar, the on-demand mobility platform that offers ‘cars-as-a-service’ solutions.

To support COVID-19 vaccination efforts, GoCar is collaborating with the Kampung Tunku ADUN in Selangor to offer free shuttle service for seniors (60 years or older) and persons with disabilities. Available until August 31, 2021, the GoVax free shuttle service is offered to senior citizens and persons with disabilities who do not own private vehicles or who have difficulties accessing public transportation.

They can use the ‘GOVAX’ promo code which will get them the first 3 hours free for round-trip bookings. However, they need to make their booking at least 7 hours in advance so booking the day before would be a good idea.

Available within Petaling district

The service is currently within the Petaling district (which includes Petaling Jaya, Subang Jaya, parts of Shah Alam and Kota Damansara) and will provide free transport to and from the designated vaccination centres at Hospital Shah Alam, Klinik Rakan Medik Petaling Jaya and the Sunway Pyramid Convention Centre. The service is available for both first and second vaccination appointments if within the offer period.

“Since the pandemic hit, we have been looking for ways to do our part and help reduce the COVID-19 impact, be it by providing free car usage to healthcare frontliners during the first Movement Control Order (MCO) or by extending more savings to customers through multiple special offers,” said Wong Hoe Mun, CEO of GoCar Malaysia.

“Now, we are expanding support to senior citizens and people with disabilities. We are delighted to partner with YB Lim, who has been tireless in championing the predicaments that these underrepresented groups face in getting around, which will hamper their ability to get inoculated,” he said.

“I am delighted to partner with GoCar in this GoVax initiative to reduce barriers and ensure these high-risk groups are sufficiently vaccinated. A key factor in making sure public health policies succeed is inclusivity. Senior citizens and people with disabilities are high-risk groups in the sense that they are more susceptible to COVID-19 and have a higher mortality rate. However, they might decide to forgo vaccination due to mobility or transportation issues,” added YB Lim.

The company is also offering free three-hour usage of passenger vehicles for residents in Klang Valley and Penang. GoCar members and passengers can have peace of mind as all GoCar vehicles are sanitised on a frequent and regular basis.

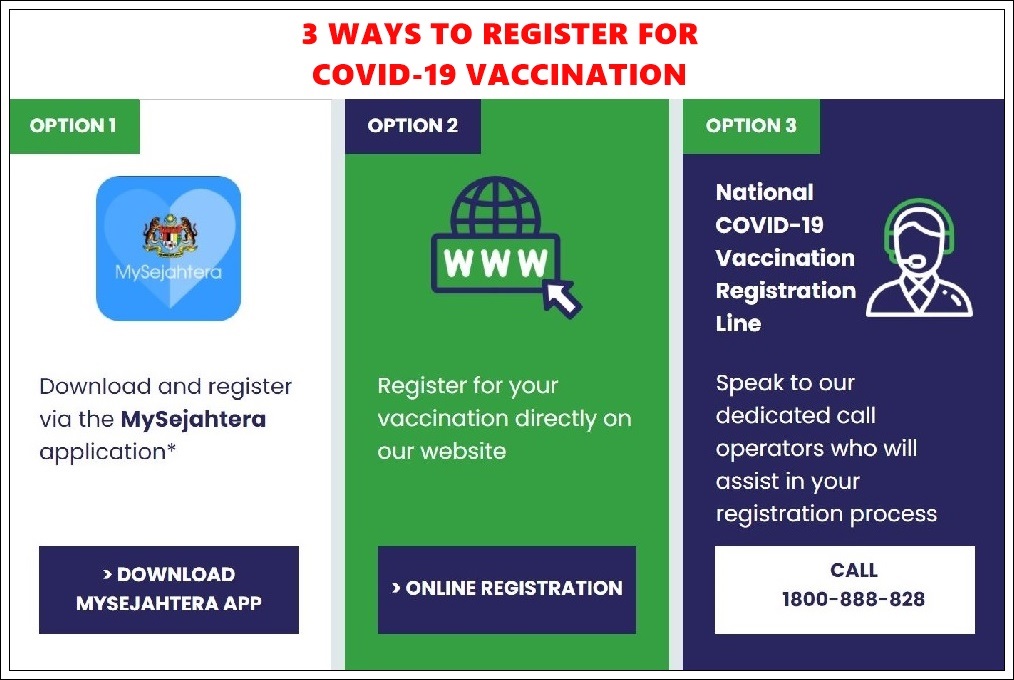

How to get the free service

Contact the GoVax taskforce at least three days before the scheduled vaccination appointment by calling the 24/7 hotline 1 300-30-2633. Slots are limited and will be allocated on a first-come, first-served basis. You will be asked to provide your name, IC number, mobile phone number and address for verification and coordination. Confirmation will be given and the person should be ready half an hour before the scheduled pickup time with IC/MyKad and mobilephone and proof of vaccination appointment.