After a year of unprecedented challenges, Proton closed 2020 on a high with another increase in sales, following a previous landmark performance in 2019. Despite losing over 2 months of vehicle production as well as sales due to the MCO (Movement Control Order), the company was still able to sell 109,716 vehicles for the whole of 2020 after a final month of 13,306 units.

The 2020 volume represented an increase of 8.8% over the 100,821 units sold in 2019, and Proton says it is the only major automotive company to record growth in Malaysia. Its market share for the year also increased to an estimated 21.1%, a significant 4.4% increase.

Main drivers of volume growth

The main drivers of volume growth were the extensively updated Persona, Iriz, Exora and Saga, which all posted higher numbers in 2020. The X50 surpassed expectations despite its later than planned arrival. The sales performance, combined with a 49.8% increase in export volume, allowed Proton to buck the trend of the Malaysian automotive industry which is expected to contract by an estimated 13%.

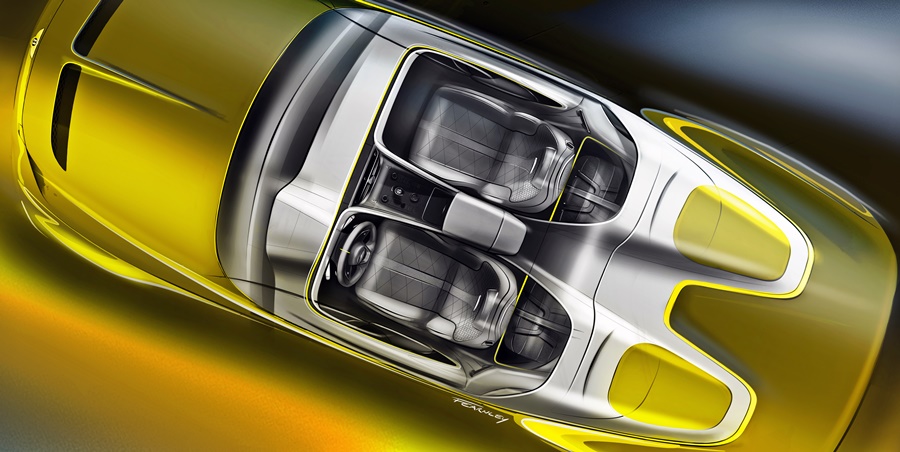

In terms of individual performance, each Proton model ended the year near the top of their respective segments. The Saga remains as the company’s bestseller for 2020, while the launch of the X50 and continued strong sales for the X70 combined to make Proton the leading SUV brand in the country.

“We are grateful to have achieved this level of performance against the backdrop of 2020. To describe it as challenging would be an understatement but we persevered. Our results were backed by many factors, trust from our customers, support from the government, commitment from vendors, resilience of our dealers and also the diligence of our staff,” said Dr. Li Chunrong, CEO of Proton.

Strategic management and decision-making

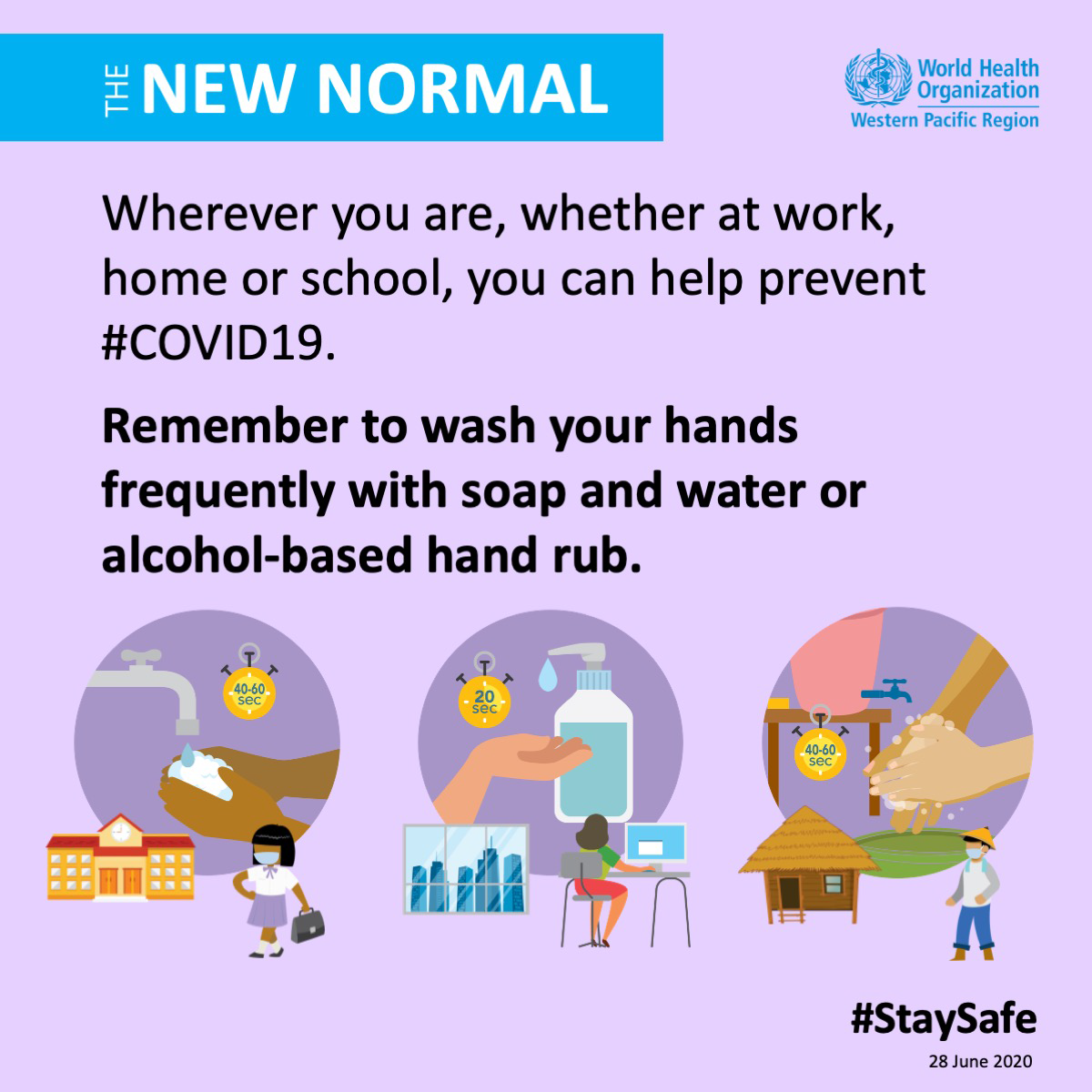

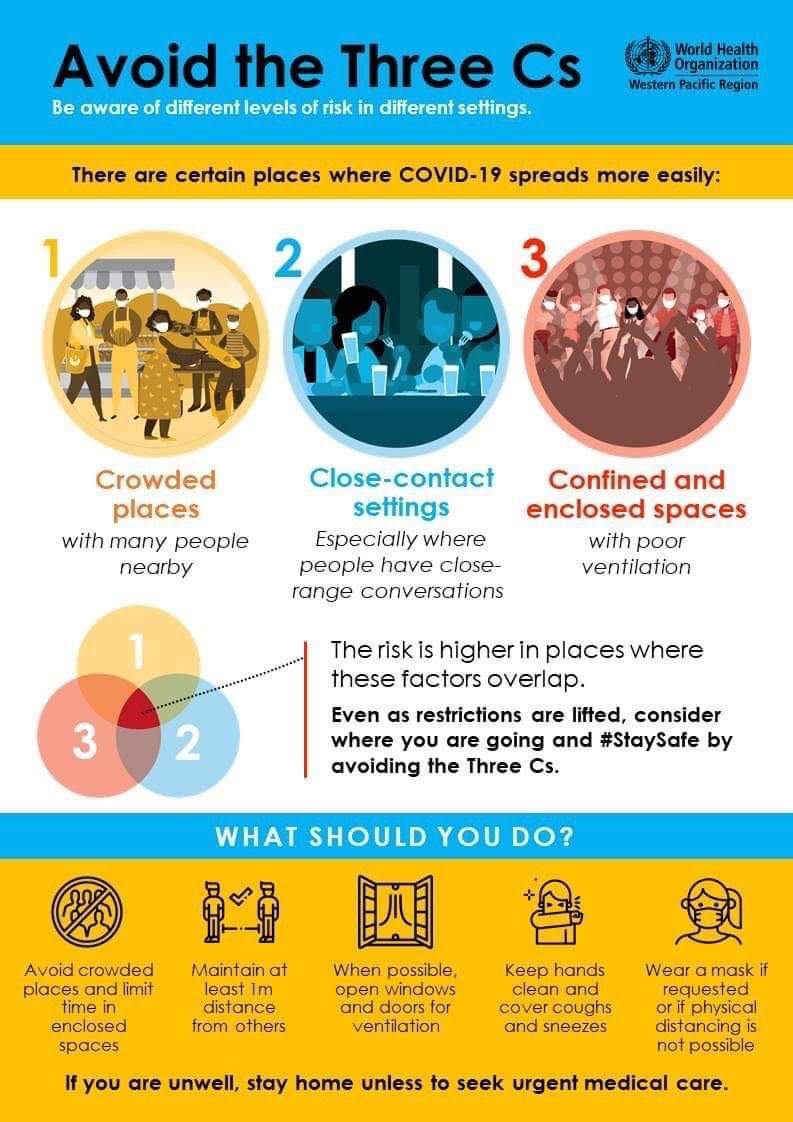

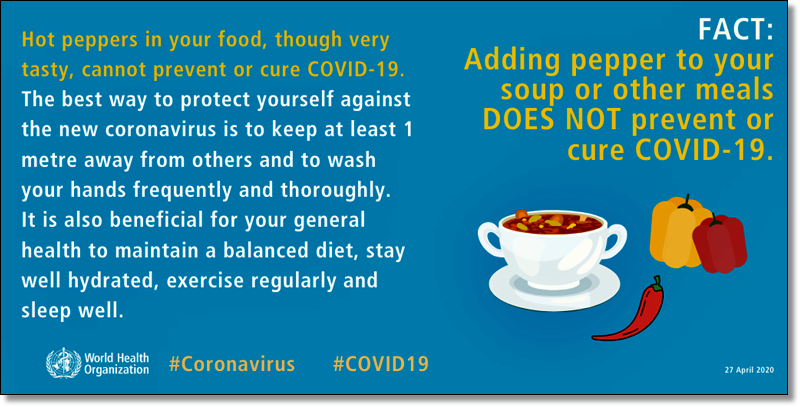

COVID-19 brought economic activity to a complete halt and its adverse effects required quick, prudent and tough management decisions. Fortunately, with the last few years of vigilant cost control and improved efficiencies, the company was able to react quickly to the crisis. This meant that despite the shutdown, there were no layoffs or salary cuts. More importantly, constant monitoring and agility allowed the company to ramp up production very quickly after the lockdown.

Post-lockdown, Proton was rigorous about safety for both customers and employees. Stringent protocols were deployed and are still being followed to ensure that all customers, partners and employees can interact with peace of mind.

Still, like all other industries dependent on a global supply chain for components, the company was affected by the availability of parts for producing new cars and replenishing its spares. This caused delays that, in some instances, severely increased waiting times for both sales and service customers. However, steps have been taken to address these issues and a marked improvement in the coming year is promised though, in the short term, some delays will persist.

Continued push in manufacturing and quality

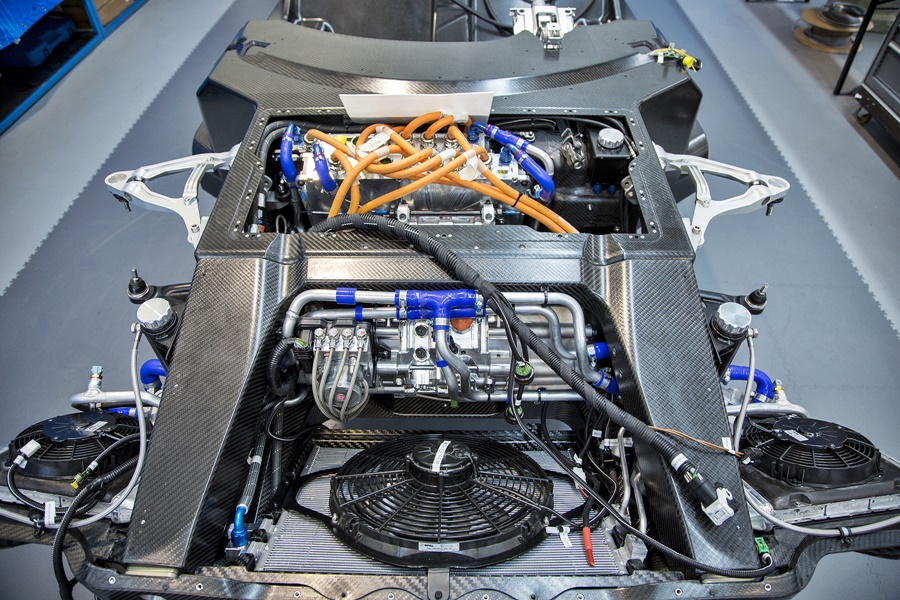

A key component in Proton’s performance for 2020 was the results of its investments in manufacturing and quality. This was both in the areas of hardware and software. Aside from technology, new processes and systems were introduced to drive an increase in capacity and precision. This was exemplified not only with the increased volume but with the smooth introduction of the X50 at the company’s new production line at the Tanjung Malim factory in Perak, which also makes the Persona, Iris and X70.

Proton also reports that it markedly improved its Global Customer Product Audit (GCPA) score demonstrating that its quality initiatives are coming to fruition. The company was able to do this despite manufacturing being the most severely impacted by the pandemic.

Export growth in trying times

Despite the restrictions placed on the global movement of goods, 2020 saw a strong year for the company’s export division, with a bumper month in December. The first locally assembled Saga roll-off the assembly line in Kenya and the model also made its debut alongside the X70 in Pakistan. Both models are currently imported in CBU form from Malaysia but will soon be assembled in Karachi when the new assembly plant is completed later this year.

The X50 meanwhile entered its first export market when it made its international debut in Brunei last month. It is the fourth Proton model to be launched in the kingdom in 2020 after the latest Persona, Iriz and Saga.

Raising the retail game

Proton increased its footprint nationwide with another 20 3S/4S outlets, bringing its network size to 140 by the end of 2020. The company continued its programme of upgrading to make a difference in the entire customer value-chain. In striving to deliver a premium brand experience, it paid special focus to revamping the back-end of the business, especially in the areas of after-sales and parts.

While already showing results, these efforts are part of Proton’s plan for the long-term evolution of its business. As such, 2020 also saw Proton change from a retail sales model to a wholesale one with the transfer of ownership of 49 of its branches. This allows the company to focus more on product development, product quality, after sales service and exports while opening the door for dealers to expand the envelope of customer service.

“2020 was a real test of Proton’s mettle as we had only just begun our new trajectory. The nature of this pandemic for an organization like ours, which depends on global supply chains, put great strain on the business. However, a combination of good strategy and hard work has left us not only with an increase in sales against a decreasing market but a renewed belief in our product strategy, quality and commitment to our customers,” Dr.Li said.

“At the same time, we also saw to it that we did our part for the country, which all of us at Proton are especially proud of. We will continue to put the pedal to the metal in 2021 and strive to improve all aspects of the business,” he added,

Proton sales and export volumes higher in 2020 in spite of pandemic