Depending on which segment of the car market you look at, manual transmissions are diminishing in popularity and some carmakers have even stopped offering them. The two giant markets of North America and China see more vehicles with automatic transmissions being sold each year but in Europe and other regions, there is still healthy demand for what is also referred to as the ‘stick shift’.

Until the 1980s, when electronics started to be used to manage automatic transmissions, they were seen as being a hindrance to performance. American drivers liked them as they worked fine with the big engines but on smaller engines, they took away the zip and worse, caused higher fuel consumption. So many motorists maintained the idea that if you wanted to have better fuel economy and you wanted to enjoy driving, stay away from an automatic.

Small number of innovations

The manual transmission has not evolved much since it is a simple unit. From the 1970s onwards, additional gears were added although five has been pretty much the norm for some time. There have been some innovations, a notable one being the TREMEC 7-speed transmission in the Chevrolet Corvette with its 1-4 ‘skip-shift’ strategy to improve fuel economy. Rev-matching technology, which first appeared in the Nissan 370Z, is another advancement that helped less skilled drivers enjoy shifting like a pro.

Although automatic transmissions have been the subject of much improvement and technological advancement, it appears that companies like Volkswagen have not stopped trying to make manual transmissions better. The numbers must still make commercial sense for the engineers to get money to work on them.

New gearbox can reduce CO2 emissions, raise efficiency

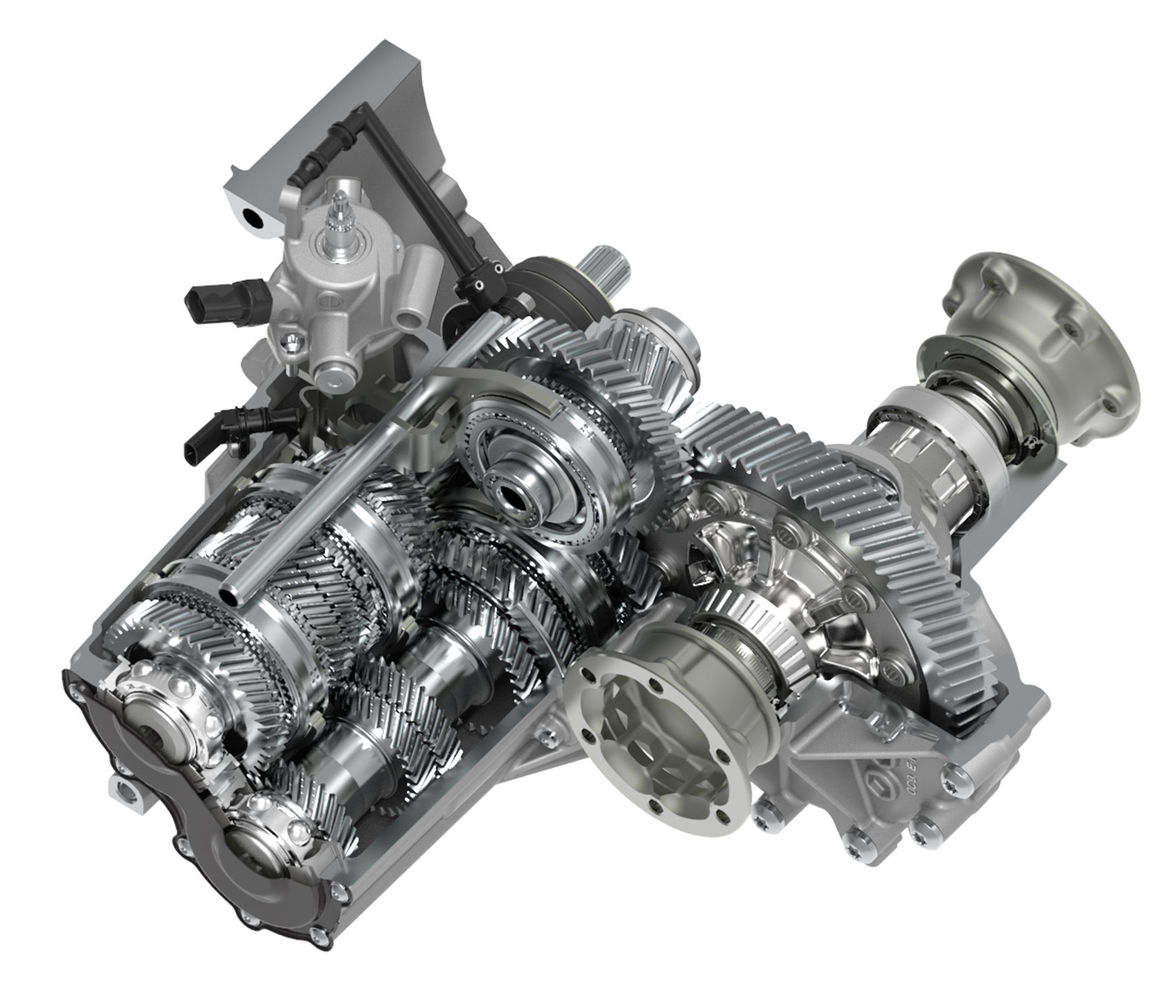

Recently, the carmaker announced its new MQ281 state-of-the-art manual gearbox which has better operating efficiency and is claimed to reduce carbon dioxide emissions by up to 5 gms per kilometre. The new Passat is the first model to be equipped with the MQ281, and this will be followed by almost all models of the Volkswagen Group.

The trend towards vehicles from the SUV segment with large-diameter wheels places high demands on the gearbox. “With the MQ281, we have developed a highly efficient manual gearbox that reliably meets these demands – and is soon to be introduced into a number of vehicle classes in the volume segment,” explained Helmut Gobbels, Head of Manual Gearbox and Four-Wheel Drive Development at Volkswagen.

The MQ281 has a torque spectrum of 200 to 340 Nm, which means it completely or partially supersedes the current Volkswagen gearbox designs with the internal designations MQ250 and MQ350 respectively.

It is based on a 2.5 shaft concept and boasts a high gear spread of maximum 7.89. On the one hand, this guarantees good driving off performance – even for heavy vehicles with large wheels – and facilitates, on the other hand, ‘downspeeding’, which is (fuel-saving) driving in high gears with low engine speed.

New oil conduction system

Development of the new gearbox focussed primarily on improving efficiency. “Here we employed virtual development methods,” said Gobbels. “This enabled us to design a completely new oil conduction system. Using a variety of oil conduction measures, we are able to achieve a uniform and optimum lubrication of gear wheels and bearings, reducing the amount of lifetime oil required to just 1.5 litres.” To further reduce friction, a bearing concept adapted to the gearbox was developed. The design used friction-minimised bearings with low-contact seals.

Material use and its distribution for the gearbox housing was also optimised. With the aid of a further virtual development tool, a strength-optimised housing structure could be designed. The new housing supports the noise requirements of today (avoidance of undesired secondary noises) and therefore ensures improved driving comfort through less audible and noticeable vibrations in the vehicle.

The Volkswagen Group, with its huge production volumes, is one of the few carmakers that can afford to make its own transmissions, rather than source them from specialists like ZF or Aisin Seiki. It will be produced at two locations – Barcelona in Spain and Cordoba in Argentina.

Don’t expect it in Malaysia

It’s unlikely that we’ll get officially-imported Volkswagen models with the new manual transmission in Malaysia. In fact, since the carmaker got into marketing activities about 15 years ago, only one model has been offered with a manual transmission and that was a Polo GTI 1.8. As most other companies have concluded, there is just insufficient demand for manual transmissions in this market. One company importing a small hatchback from Thailand had to stop doing so when the factory said that the volume taken was so low that the price would be higher than for the automatic variant.