For a brand with a history of over 130 years, the transition to a new era of design and technology has to be managed carefully. There is the legacy and the birth of the brand to keep in mind while at the same time, the future must be shown as well.

At Design Essentials 2019 in Nice, France, Mercedes-Benz Design is presenting the Vision Mercedes Simplex, a sculpture embodying the heritage and future of the luxury brand. “Only a brand that is as strong as Mercedes-Benz is capable of the physical symbiosis of history and future. The Vision Mercedes Simplex symbolises the transformation of the brand-specific luxury of Mercedes-Benz,” said Chief Design Officer Gorden Wagener.

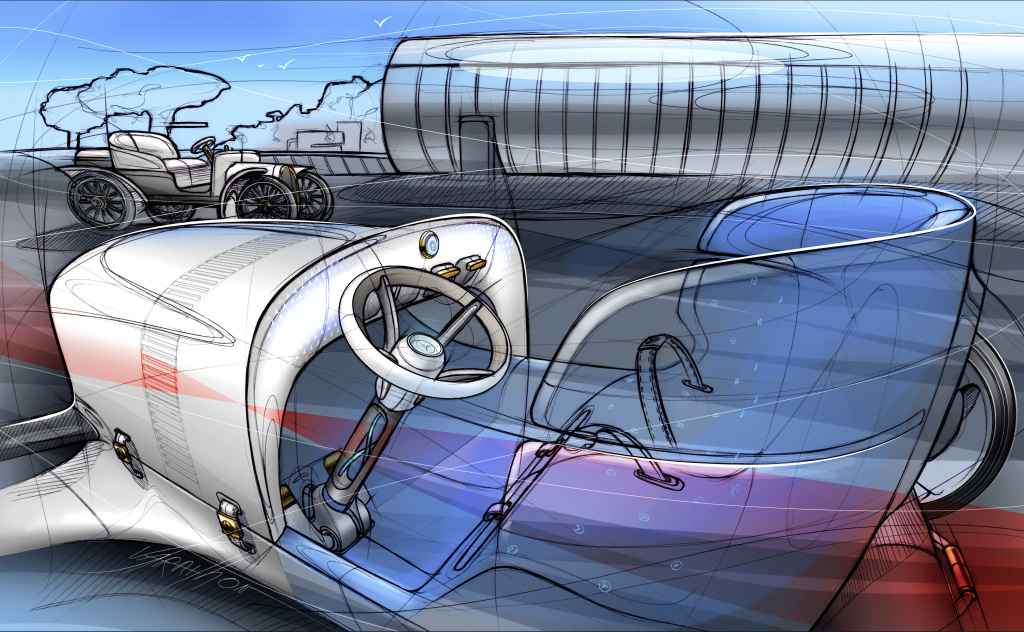

The inspiration for the Vision Mercedes Simplex goes back to 1901, when the history of mobility changed radically. At Race Week in Nice, a car the world had never seen before appeared on the starting line: a high-performance car which Daimler-Motoren-Gesellschaft had developed at the suggestion of the visionary Emil Jellinek.

The designs which were the norm back then were still closely related to motorised carriages. The Mercedes 35 PS, named after Jellinek’s daughter Mercedes, appeared with a completely new vehicle architecture and dominated the competitions in Race Week, which took place on the famous racetrack from Nice to La Turbie, right at the heart of what is now the Mercedes-Benz International Design Centre Europe.

The design is acknowledged as the first modern car and it heralded in a new era. Nearly 120 years ago, the transformation, away from a high motorised carriage to a flat vehicle design with a light high-performance engine installed low down in the frame and a honeycomb radiator organically integrated into the front, was the pioneer of success and role model for all the cars that were to follow, whatever the brand. The vehicle layout presented for the first time over a century ago remains to this day the technical basis of all cars.

The Vision Mercedes Simplex recalls this historic event and carries the pioneering spirit and the styling characteristics of those days far into the 21st century. Its message? The passion for luxury and innovation is part of the Mercedes-Benz brand DNA. This brand DNA gives Mercedes-Benz the strength to set new standards in mobility over again, yesterday, today and tomorrow.

Two-seater with forward-looking digital luxury

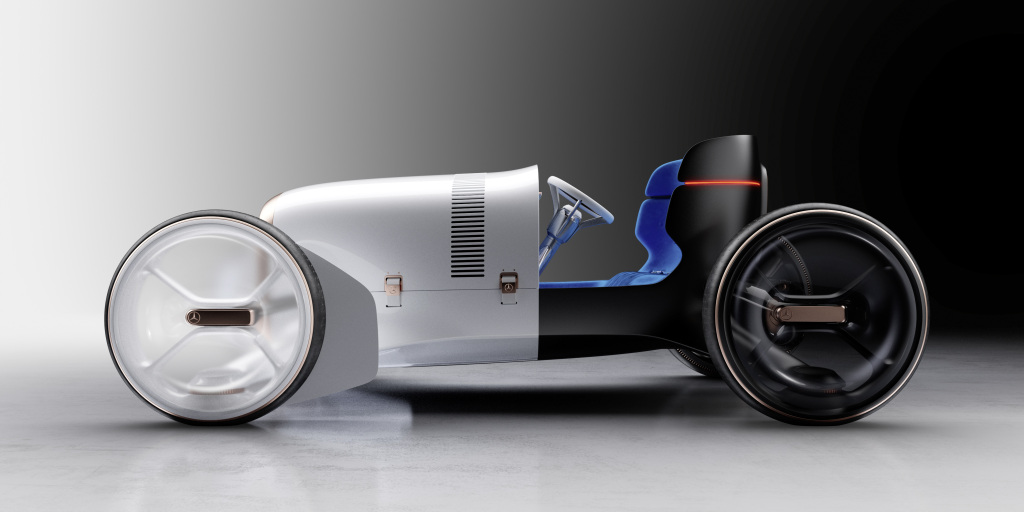

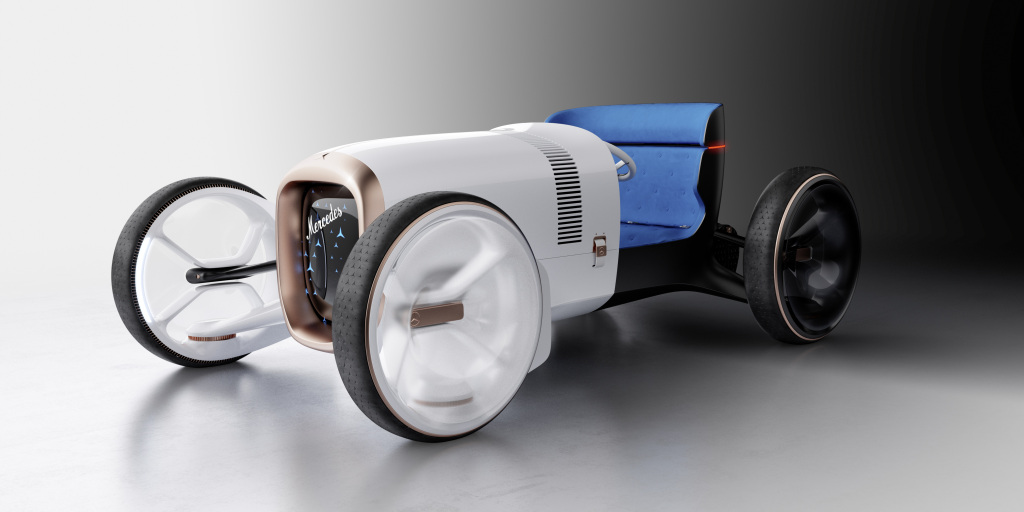

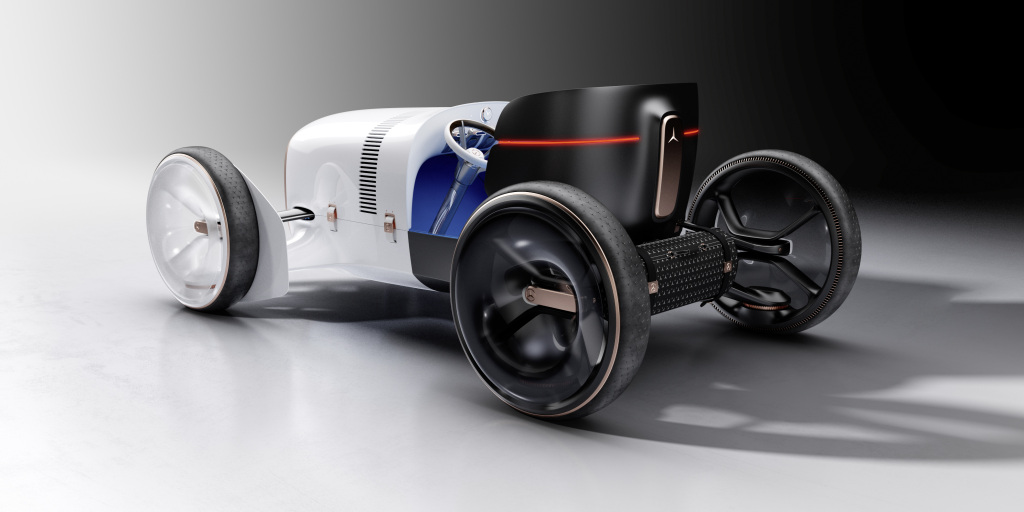

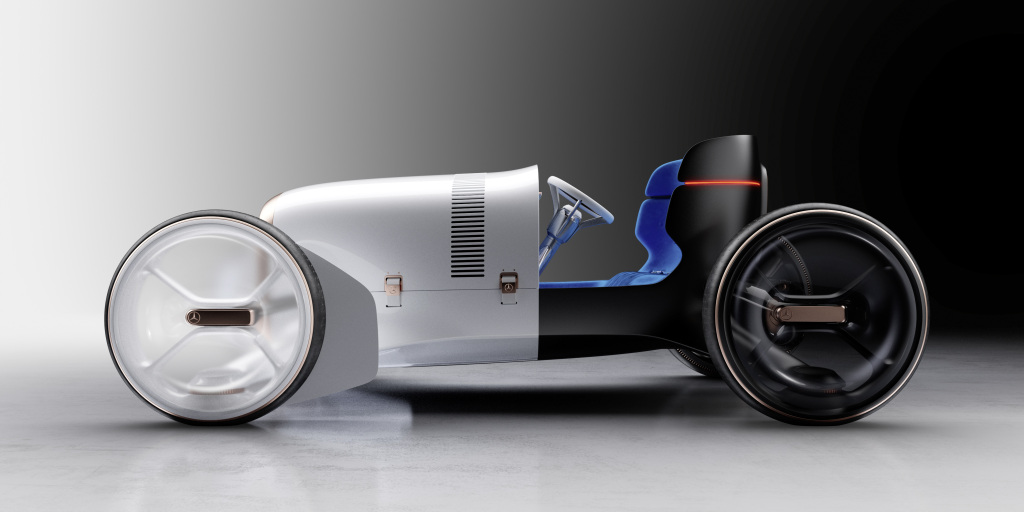

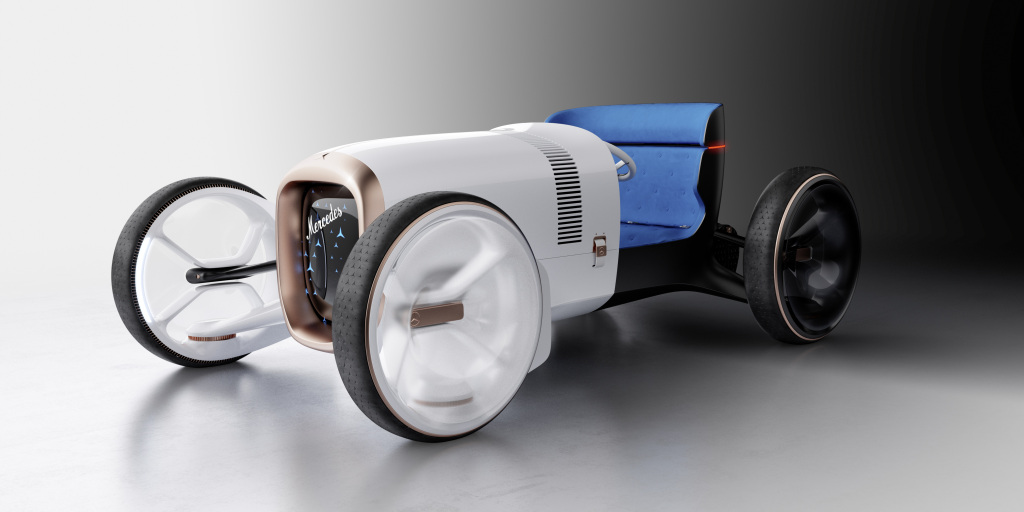

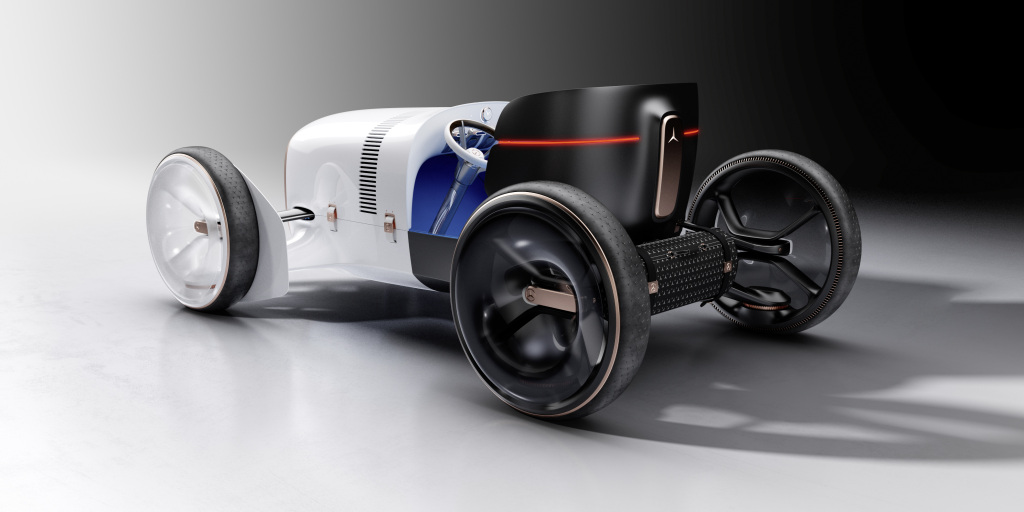

The Vision Mercedes Simplex reinterprets the historic Simplex as a two-seater with freestanding wheels, an alternative drive, User Interface and a thrilling design. Its body with the dominant horizontal alignment sits as a monocoque amid the 4 large wheels, which form the outer points of the vehicle.

The resolutely vertical colour separation into a white front section and a black rear section follows the historic example. The transparent trims on the wheels reflect lightness and efficiency, as do the aerodynamic surface areas between the front wheels and the vehicle body. The entire sculpture lives from the interplay between clearly and powerfully drawn surfaces and precise technical details.

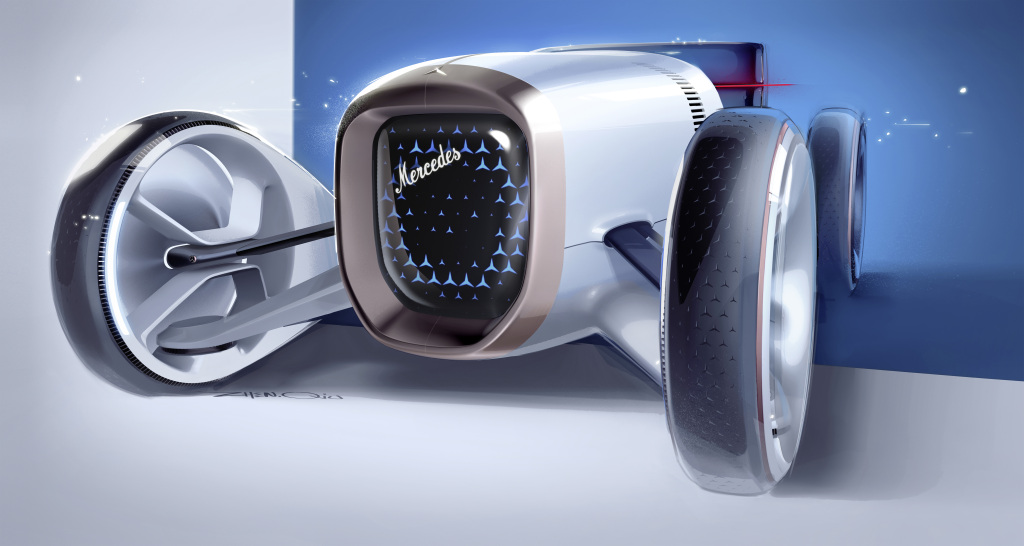

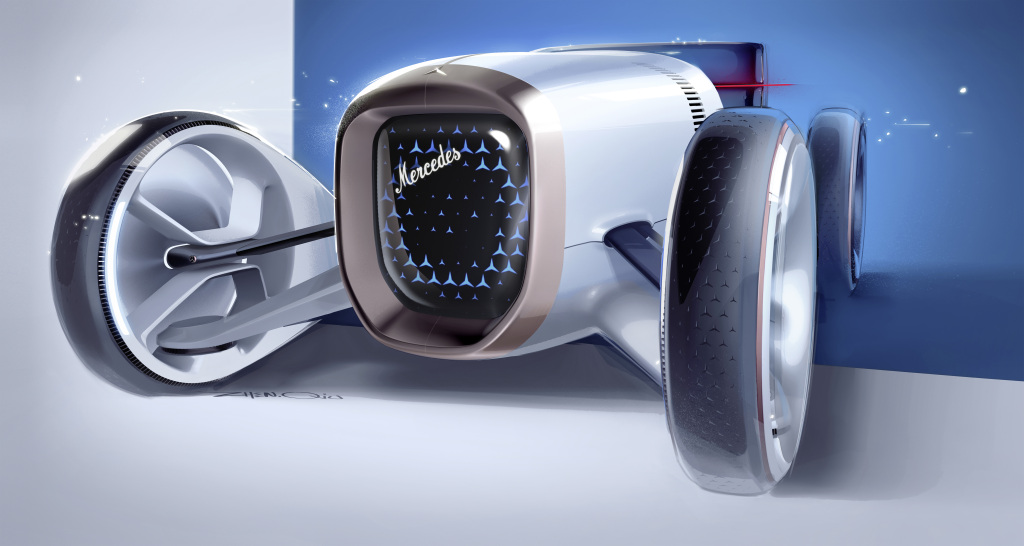

Radiator grille a symbol of digital transformation

The radiator blends a dominant frame in rose gold – reminiscent of the bronze radiator grille of the historic example – with an opening in the form of a large lens-shaped Black Panel/3D display. This is where the famous MERCEDES lettering is digitally superimposed, as are animations which provide information on the vehicle status. This detail, too, is a symbol of the transformation of the luxury brand Mercedes-Benz into the digital world.

The decentralised wheel location components unite aesthetics and engineering artistry in a unique way. The omission of a windscreen – as on the historic role model – reinforces the uncompromisingly sporty character and allows a seamless transition from the front-end flap to the instrument panel. The slim reversing lamps which are horizontally integrated into the rear section separate the upper section from the lower section of the exterior shell, which envelopes the occupants like a protective cocoon.

Perfect handcraftsmanship is also evident on the leather bag which rounds off the tail end of the vehicle body and – with its contemporary interpretation – is also themed around the historic vehicle.

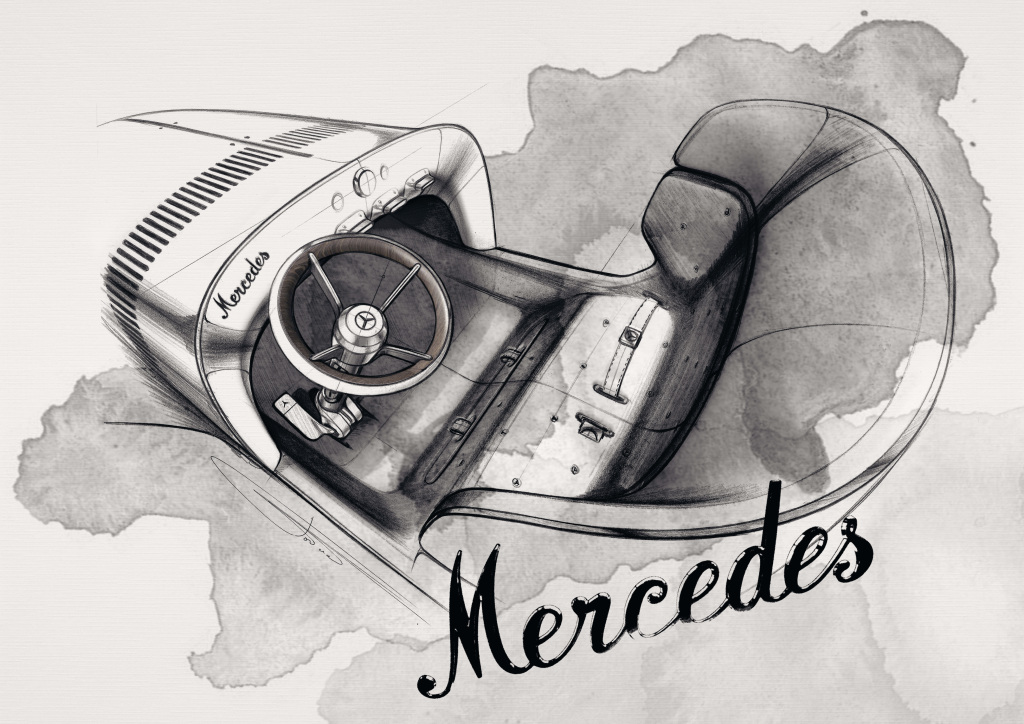

Homage to history

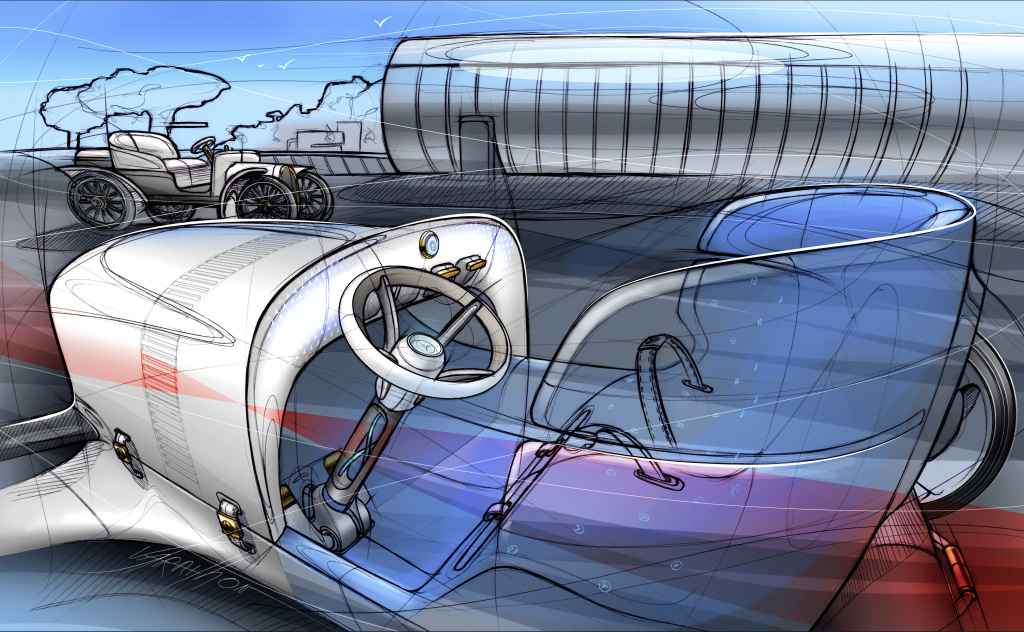

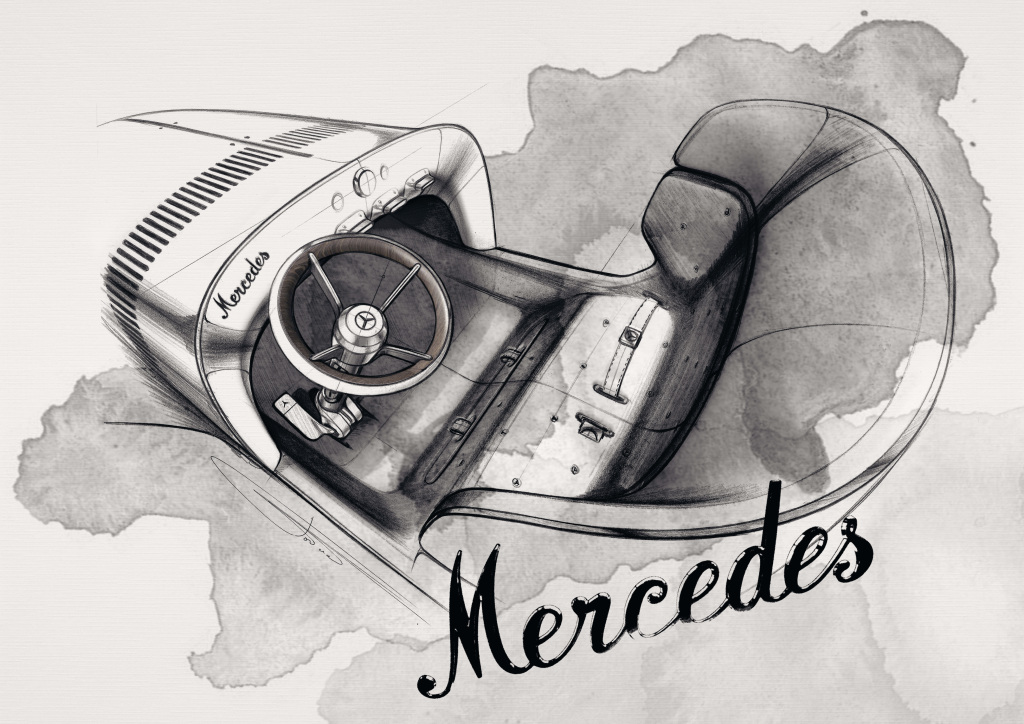

The entire interior pay homage to the successful history of Mercedes-Benz and the DNA of the Simplex racing car – systematically reduced and nevertheless highly emotively appealing. A seamless transition between the exterior, interior and User Experience reflects the holistic approach of the Mercedes-Benz design philosophy. This is particularly evident in the flowing, flute-like transition between the bonnet and instrument panel with its reduced interface which works with projections. The seamless look continues into the footwell.

The fashion world is reflected in the interior with exclusive accessories like the high-quality openers for the stowage compartments. The bench seat is inspired by stylish furniture, the hand-made Chesterfield quilting denotes a contemporary interpretation of classically luxurious handcraftsmanship. The colour-and-trim concept, including the azure blue upholstery cover which transitions seamlessly into the footwell, is inspired by the colours of the Cote d’Azur.

UI/UX design: digital luxury

The UI/UX design demonstrates a Mercedes-Benz vision of digital luxury. The driver is only shown precisely the information they actually require in the specific driving situation. The heart of the instrument panel is a physical rose-gold-coloured instrument on which dynamic digital content is projected.

This combination of mechanical beauty and intelligent digital content is described by the Mercedes-Benz designers as ‘hyper analogue’. The right information is shown on the display at the right time, eg speed, navigation instructions or vehicle information. Other information is displayed on the instrument panel depending on the situation.

A star pattern fused with the material of the instrument panel creates a large surface onto which information can be projected for a certain amount of time. Thanks to the simple presentation and the size of the display the driver can take in relevant information and yet still concentrate fully on the road at all times.

Click here for other news and articles about Mercedes-Benz in PISTON.MY