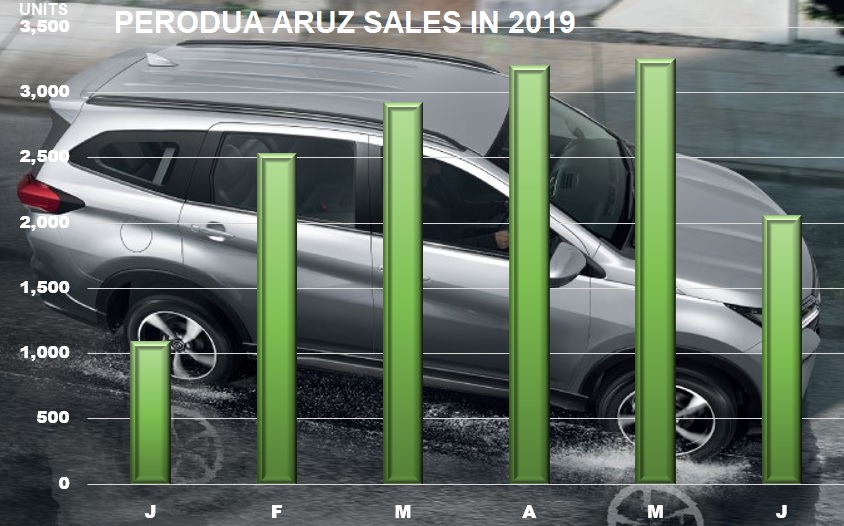

It’s evident that Proton sales this year have been growing steadily and the brand has been edging upwards on the chart towards Perodua, which has been No. 1 since 2005. Yet, Perodua remains confident that in the remaining 6 months of 2019, it will continue to maintain its strong sales and has even revised upwards its sales target for the year to 235,000 units. This is 4,000 units higher than the 231,000-unit target announced when the year began.

To put things into perspective, Perodua sold 227,243 vehicles in 2018, which was the highest annual sales achievement in its history. In the first half of 2019, Perodua sold some 121,800 vehicles – 4% more than the 117,100 units it sold in the same period last year – backed by sustained healthy demand for all its models.

Speaking to the media today, Perodua President & CEO, Dato’ Zainal Abidin Ahmad, said that from January through June this year, total bookings stood at 190,765 units, more than 3% up on the 184,949 orders collected in the same 5-month period last year.

“The increase in demand for our vehicles in the first 6 months of 2019 has had a positive impact on the automotive ecosystem as a whole, with parts purchases amounting to RM2.7 billion during this period,” Dato’ Zainal Abidin Ahmad said. “Based on our forecast for the second half of the year, we expect to purchase a total of RM5.4 billion worth of parts for the whole of 2019.

He said that Perodua is also working with the Daihatsu Motor Company of Japan to further develop its component suppliers to explore markets beyond Malaysia, and that this forms part of the company’s commitment to build Malaysia’s automotive support industries.

Second half outlook

On the outlook for the second half of 2019, Dato’ Zainal said, “There is good news in the market as the central bank has reduced the overnight policy rate, which will help in promoting consumer spending. That said, we should remember that last year there was a big incentive for consumers to buy cars with the tax holiday, which was announced after the outcome of the country’s 14th General Election.

“Based on our internal calculations, the industry has outperformed expectations in the first half of this year – Malaysia’s Total Industry Volume (TIV) has grown 2.4% to 296,800 units,” Dato’ Zainal added.

He explained that the tax break incentive had a one-off effect on the market and that consumers and automotive players alike took advantage of the situation. “With this in mind, we believe that the second half of the year will not be as healthy as what was recorded last year. The momentum of the first half is likely to reduce in the second half,” said the President and CEO.

Working harder on exports

“We have reached a stage in our history where we are earnestly seeking to build our brand abroad in a sustainable manner. However, this is on a long-term scale as brands do need time to build. Our hope is to make Malaysia proud,” he added.

Although Perodua had, in earlier years, been exporting its cars to some markets in Europe (including the UK), the increasingly stringent exhaust emission regulations had eventually impacted the exports and the cost of meeting the regulations was too high. Daihatsu too stopped exporting its products to Europe. However, in the ASEAN region, Perodua still had a small export volume and even supplied the Myvi to Daihatsu for sale as a Sirion in Indonesia under its own brand.

At the moment, Perodua exports to 7 countries and is putting in greater efforts to enter new markets in coming years. This takes time as thorough market studies are needed and the products correctly tailored to customer needs. In this respect, the experience of Daihatsu would be useful.

Recall for the Aruz

At today’s media briefing, Perodua also announced a recall for the Aruz which affects 3,000+ vehicles manufactured before February 15, 2019. The recall is precautionary and is related to the Electronic Control Unit (ECU) managing the side airbag. This is in response to an incident of unintended inflation of the airbag in a Toyota Rush in the Philippines but it is confirmed that there is nothing defective about the airbag itself.

Perodua officials explained that the road conditions in the Philippines and also in Indonesia are rougher than in Malaysia, and could be the cause. Owners have been sent letters asking them to bring their vehicles in for the precautionary check and if needed, rectification.

Visit www.perodua.com.my to know more about the models available.