The BMW Group is ushering in a new era of electric mobility with its sixth-generation BMW eDrive technology. At the Tech Days event in Landshut, the company provided insights into the development and production of high-voltage batteries and electric drive systems, all of which will benefit the upcoming Neue Klasse models. The first Neue Klasse vehicle is set to enter series production later this year at Plant Debrecen in Hungary.

Key Technological Advancements

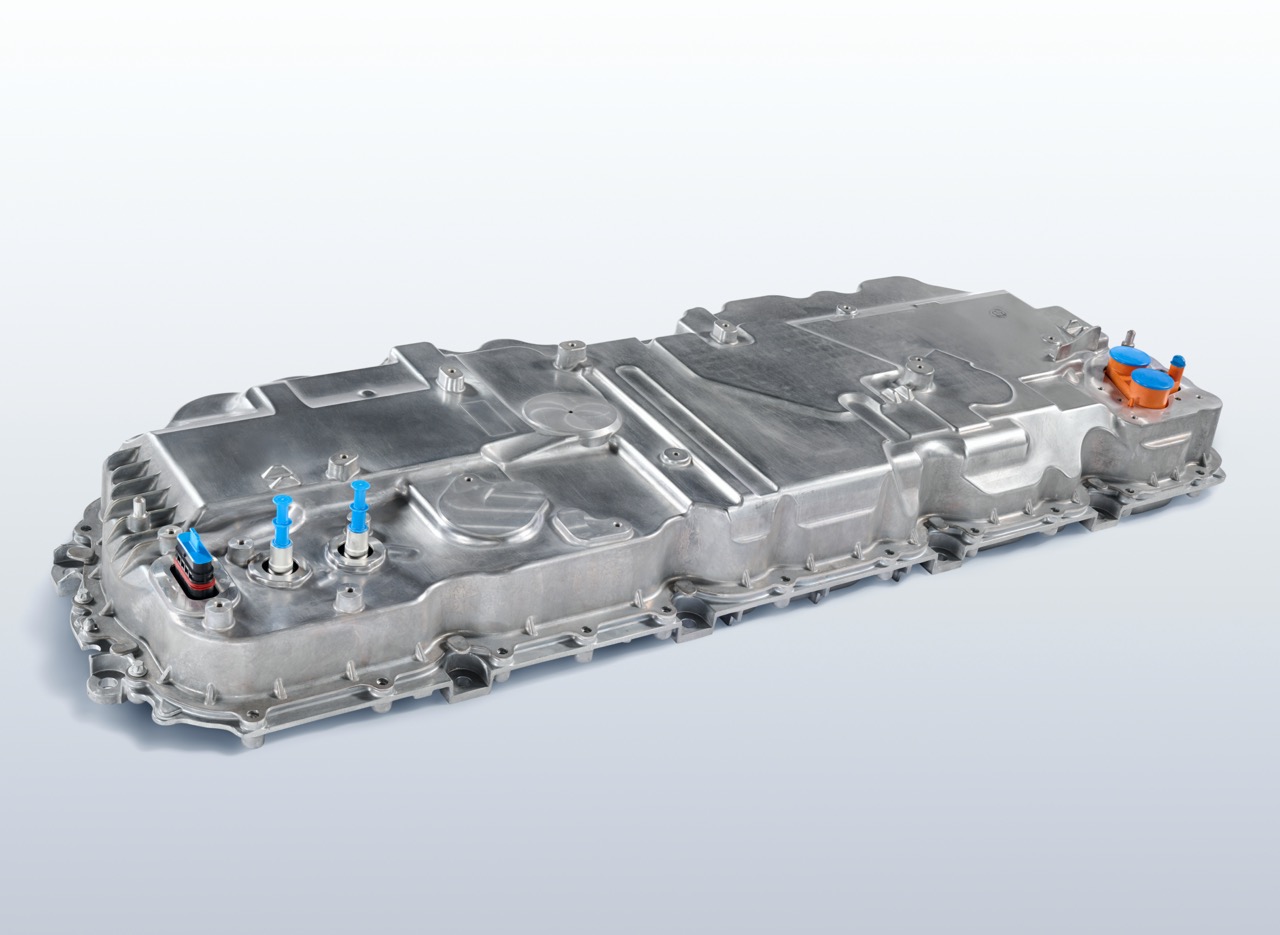

- Energy Master Intelligent Control Unit: Developed and produced at Plant Landshut, this unit manages energy distribution, power supply, and battery operation.

- High-Voltage Battery with Cylindrical Cells: A new battery design promises a technological leap, offering a 30% increase in charging speed and range.

- Electric Motor Flexibility: BMW integrates synchronous (SSM) and asynchronous (ASM) motor types to optimize performance and efficiency.

- Local-for-Local Strategy: High-voltage batteries will be assembled in five global locations—Germany, Hungary, China, Mexico, and the U.S.

- Bidirectional Charging: Gen6 batteries will support two-way charging, enhancing energy management capabilities.

Performance and Efficiency Gains

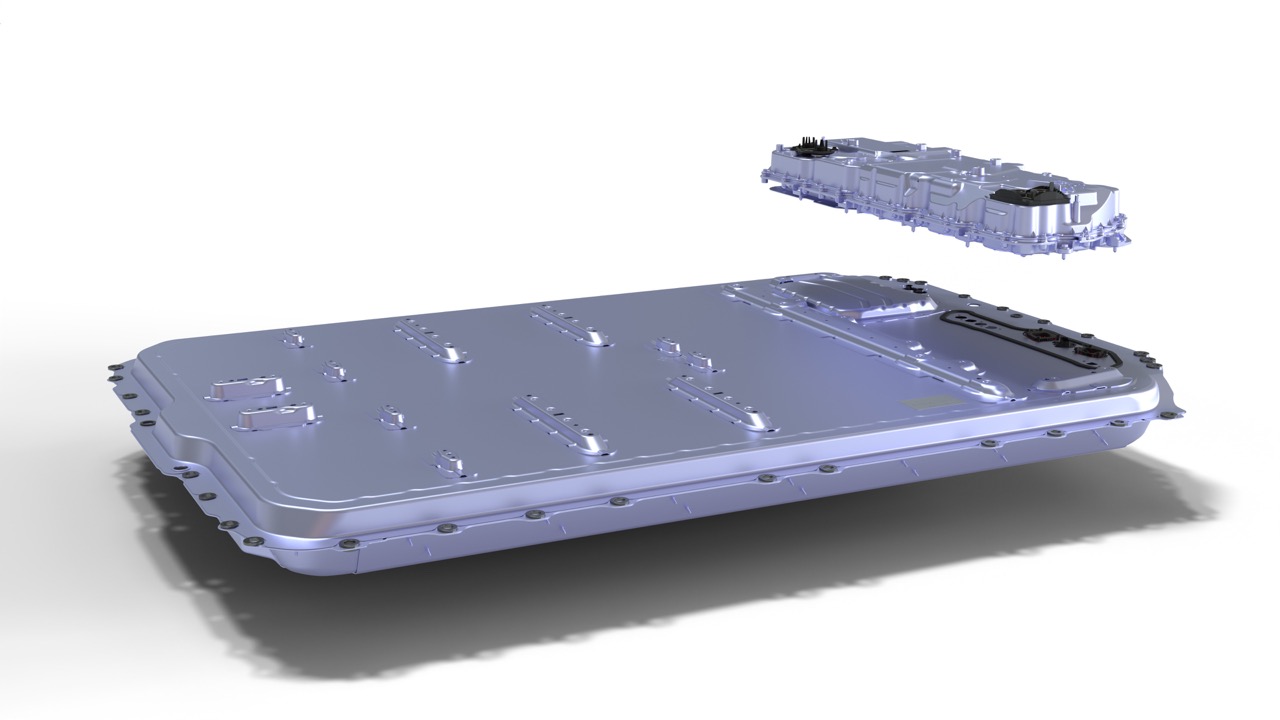

The Gen6 high-voltage battery, featuring 800V technology, delivers improved energy density and integrates seamlessly into vehicle architecture. This structural component approach—”pack-to-open-body” and “cell-to-pack”—ensures a slimmer, more adaptable design for diverse vehicle models, including high-performance BMW M vehicles.

BMW’s Energy Master serves as the central control hub, optimizing battery performance while enabling real-time remote software updates. The company has also secured multiple patents related to battery management and electronic fuses.

Sustainable Production and Recycling

BMW’s commitment to sustainability is evident in its closed-loop recycling approach. Partnering with SK tes and Encory, the company is refining battery recycling processes, and recovering key materials like cobalt, nickel, and lithium for reuse. This ensures supply chain resilience and promotes a circular economy.

Future-Ready Manufacturing

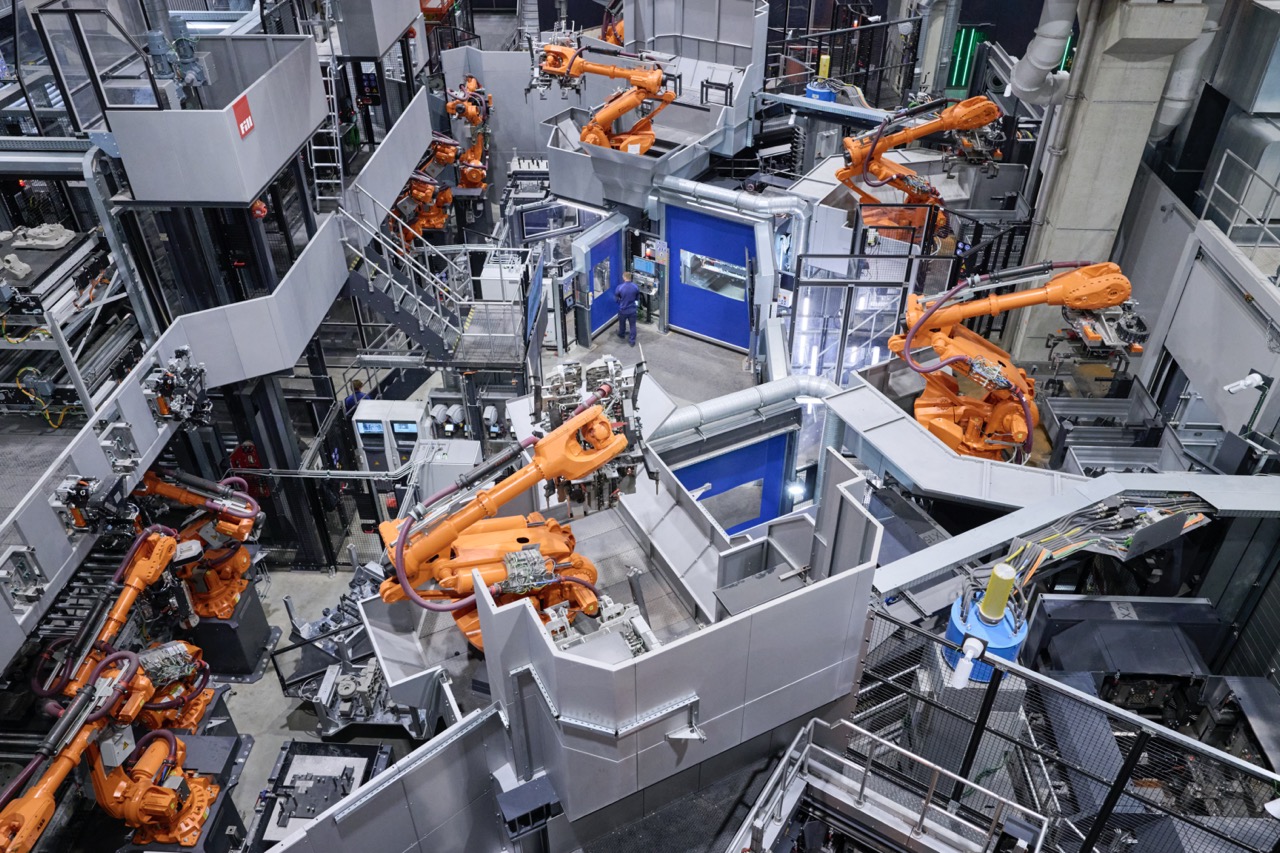

Plant Landshut will begin series production of the Energy Master in August 2025, with further expansion in mid-2026. Up to 700 jobs will be created, supported by BMW’s investment of hundreds of millions of euros. The production facility will feature 400 robots and AI-based monitoring systems to maximise efficiency and quality.

Advanced Electric Drivetrain

BMW continues to innovate with its Gen6 electric motor technology. The primary drivetrain remains an electrically excited synchronous motor (EESM), while Neue Klasse vehicles will also incorporate an asynchronous motor (ASM). The combination ensures optimized efficiency and high-speed performance, with numerous patented advancements in rotor and motor design.

With these technological breakthroughs, BMW aims to solidify its leadership in electric mobility while maintaining a flexible, global approach to drivetrain solutions. As the Neue Klasse models enter production, they mark a significant step forward in the brand’s electric evolution.