Proton has officially commenced construction of its first dedicated electric vehicle (EV) production plant at its high-tech Tanjung Malim facility, marking a major milestone in the company’s transition toward local EV manufacturing. The facility, which represents an investment of RM82 million, is set to be completed by the end of 2025.

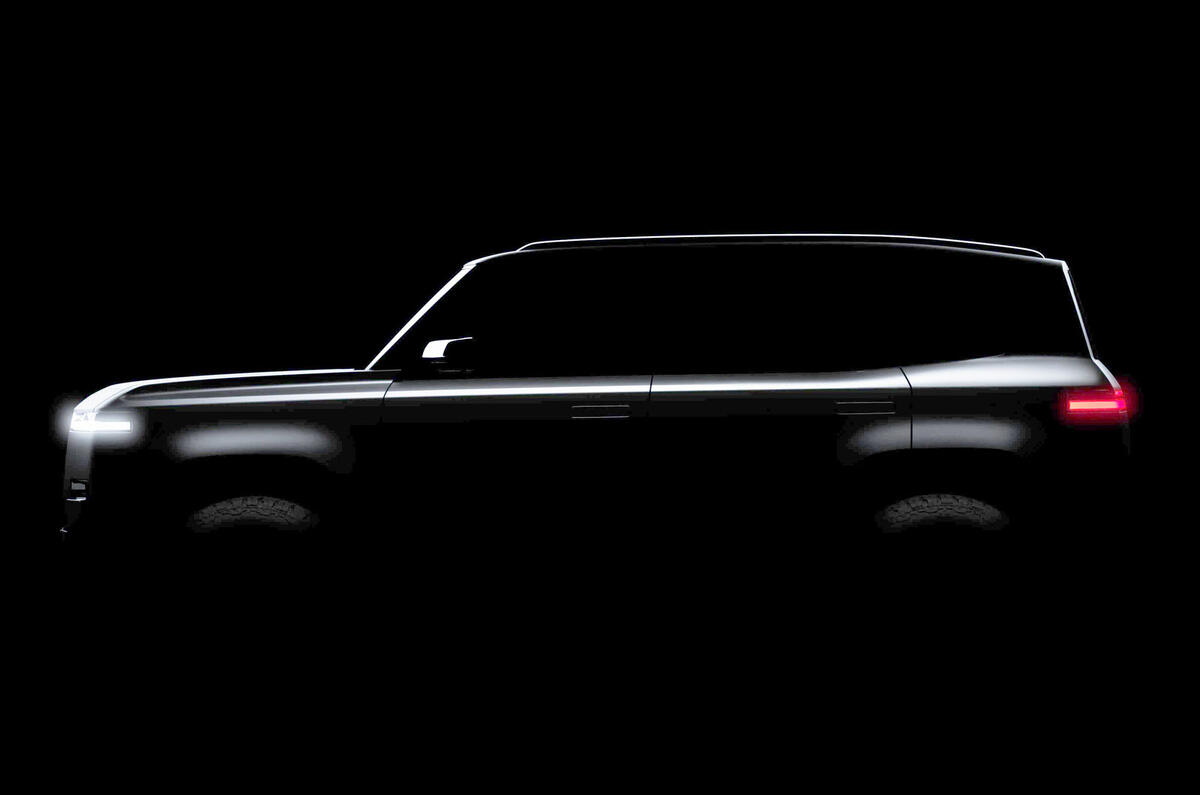

The first phase of Proton’s EV assembly plant will have an initial production capacity of 20,000 units per year. Once completed, the plant will manufacture multiple models based on the Global Modular Architecture (GMA) platform, starting with the Proton e.MAS 7, the first EV model from a Malaysian automotive brand.

The commencement ceremony was attended by Perak Menteri Besar Datuk Seri Saarani Mohamad, along with members of the state government and executive council. Representing Proton were board member Ahmad Jauhari Yahya, CEO Dr. Li Chunrong, and Deputy CEO Roslan Abdullah. Representatives from government ministries, federal agencies, and local state authorities were also present.

Proton’s new EV facility is located within the Automotive High Tech Valley (AHTV) in Tanjung Malim and aligns with Malaysia’s EV industrialisation roadmap. This initiative supports the government’s key policies, including the New Industrial Master Plan (NIMP), National Automotive Policy (NAP 2020), Low Carbon Mobility Blueprint (LCMB), and New Energy Transition Roadmap (NETR).

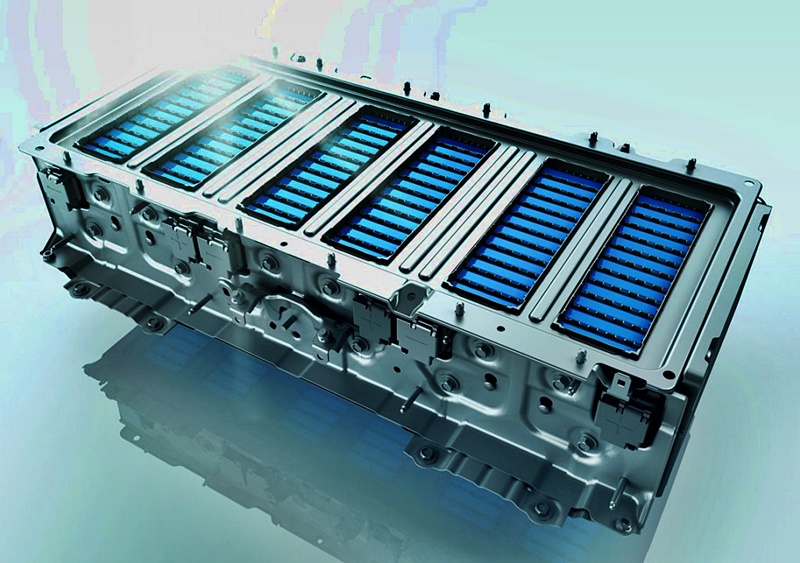

The plant will feature cutting-edge smart manufacturing technologies to ensure high-quality production with efficiency and minimal environmental impact. The facility will integrate robotics, cloud-based plant management, industrial Internet-of-Things (IoT), and Industry 4.0 technologies to optimise operations.

Despite the high degree of automation, Proton estimates the facility will create over 200 new jobs specializing in EV industrialization and technical services. This does not include additional job opportunities within the AHTV vendor community, which will ramp up operations to supply critical components for EV assembly.

Proton has also outlined a second phase of expansion in anticipation of increasing EV demand. This phase will boost production capacity to 45,000 units annually, depending on domestic and export market demand.

Proton’s transition to EV production began in 2023 with the establishment of PRO-NET, which introduced smart electric vehicles to Malaysia. The launch of the Proton e.MAS 7 in 2024 marked the company’s entry into the local EV segment.

“Today, we take another step toward realizing our vision of manufacturing and developing EV models in Malaysia. The vehicles produced here will serve both domestic and export markets while driving EV market growth,” said Dr. Li Chunrong, CEO of Proton.

“Once completed, this new factory will focus on producing the Proton e.MAS 7 as well as future New Energy Vehicle (NEV) offerings. Ultimately, we hope our success will establish a modern and capable automotive ecosystem that encourages more OEMs to consider Malaysia and AHTV as a regional base for EVs.”

With this strategic move, Proton aims to position Malaysia as a key player in the regional EV industry, reinforcing its commitment to sustainable mobility and advanced automotive manufacturing.