BMW is taking autonomous technology beyond the highway and into its factories. The company has been refining its Automated Driving In-Plant (AFW) system since 2022, starting with a pilot project in its Dingolfing, Germany plant—the automaker’s largest production facility. This groundbreaking system has now received CE certification, paving the way for wider adoption across the European Union.

Revolutionising In-Plant Logistics

At the Dingolfing plant, which employs over 17,000 people and produces a range of BMW models (including the 5 Series, 7 Series, and Rolls-Royce bodies), AFW enables newly assembled vehicles to drive autonomously for nearly a mile. The vehicles navigate from the assembly line through a test course and onto the finishing area, all without a driver.

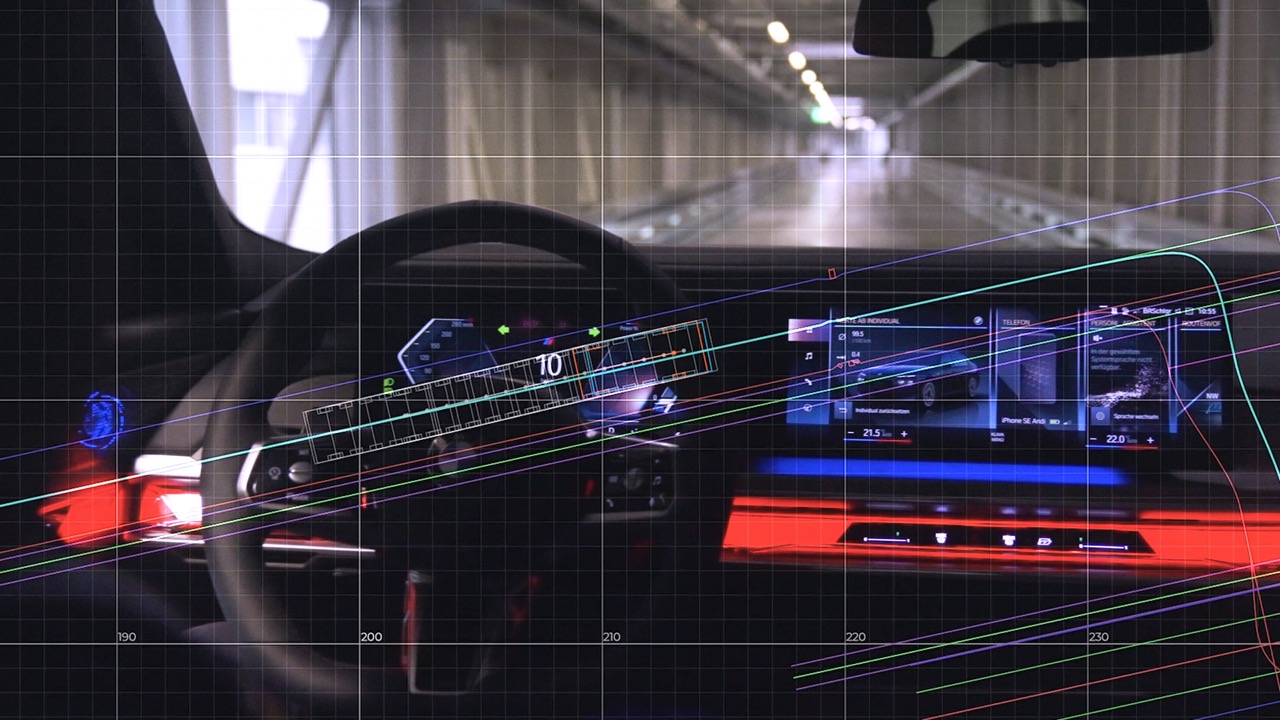

The system relies on a sophisticated LIDAR infrastructure, Europe’s largest, which tracks vehicles along their route. Unlike traditional semi-autonomous systems, the AFW process does not depend on the vehicle’s built-in autonomy features. Instead, the cars are guided by external LIDAR sensors and a cutting-edge cloud-based architecture, ensuring precision and safety throughout the plant.

Expansion to Leipzig Plant

Following its success at Dingolfing, BMW plans to implement AFW at its Leipzig plant, which produces around 1,000 vehicles daily across models such as the MINI Countryman, BMW 1 Series, BMW 2 Series Gran Coupé, and BMW 2 Series Active Tourer.

In Leipzig, the system is expected to handle approximately 90% of vehicle movements within the plant. Future upgrades will enable AFW to guide vehicles through the complete testing zone and eventually to outdoor loading areas, ready for shipment by truck or train.

Paving the Way for Broader Autonomous Applications

BMW is continually refining the AFW system, aiming to integrate on-board vehicle sensors into the process. These additions could enhance the LIDAR infrastructure’s efficiency, making the system even more precise and adaptable.

Beyond its manufacturing plants, BMW sees potential for the AFW technology to contribute to the evolution of consumer-facing autonomous driving systems, incorporating insights gained from the factory environment into future vehicle designs.

A Look Ahead

The success of AFW underscores BMW’s commitment to innovation and efficiency in manufacturing. By automating internal logistics, the automaker not only streamlines its production processes but also lays the groundwork for advancements in autonomous vehicle technology.

With Leipzig on track to integrate the system and plans for further enhancements, BMW is set to lead the charge in applying automation to both factory floors and public roads.