Jaguar Land Rover (JLR) is investing £500 million to transform its historic Halewood plant, originally built in 1963, into a state-of-the-art facility for electric vehicles (EVs). This overhaul is a critical part of JLR’s strategy to transition towards full electrification, aiming to sell only electric cars by 2030 and achieve zero emissions by 2039.

Key Components of the Investment:

- Expanded Production Capabilities: The plant will be equipped to produce electric, combustion, and hybrid vehicles simultaneously.

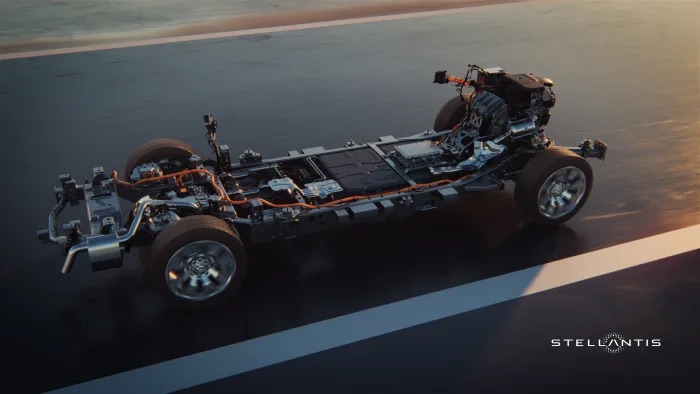

- Platform Integration: The new facilities will produce mid-size electric SUVs based on the Electric Modular Architecture (EMA) platform.

- Solar Power Integration: Installation of 18,000 solar panels, providing 8,600 GWh of energy, which will cover 10% of the plant’s energy consumption.

Facility Upgrades:

- New Body Shop: Capable of producing 500 bodies per day.

- Paint Shop Modifications: 1.4 km of improvements with additional ovens and conveyor belts to meet the demand for contrasting roofs.

- Automated Storage Tower: Built to store 600 painted bodies.

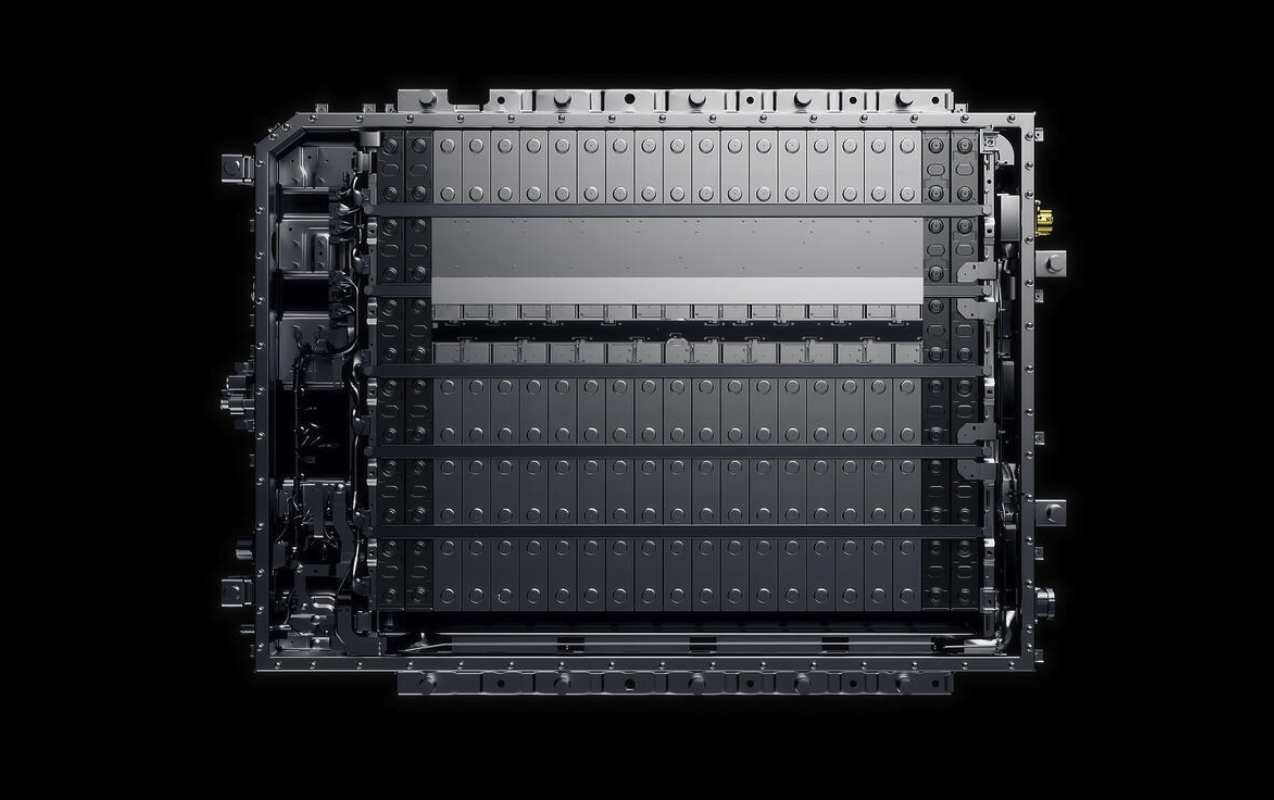

- Extended Final Production Line: Increased from 4 km to 6 km to accommodate battery assembly.

- Larger Production Stations: Extended to 7 metres to fit the dimensions of new EMA electric vehicles.

- Autonomous Mobile Robots (AMR): 40 new AMRs will aid in the installation of high-voltage batteries.

Employee Training and Integration:

- Over 1,600 employees will receive high-voltage training.

- Equipment from JLR’s Castle Bromwich site, including ABB robots and self-driving vehicles, will be integrated into Halewood’s new £16 million facility.

This investment follows a previous £250 million expansion of the plant, which added 32,364 square metres of space, further reinforcing JLR’s commitment to electrifying its vehicle lineup and future-proofing the Halewood site for the electric era.