At Volvo Cars’ Capital Markets Day in Gothenburg, Sweden, the company introduced a revolutionary approach to technology that will define its future—centred around the concept of continuously improving its vehicles over time. This shift in strategy will focus on engineering a single technological foundation, ensuring that Volvo’s cars get better with each update.

The Volvo Cars Superset Tech Stack

At the core of this strategy is the Volvo Cars Superset tech stack. This comprehensive system of modules, software, and hardware will serve as the foundational base for all future electric vehicles, starting with the EX90. The tech stack is like a set of configurable building blocks, allowing Volvo to adapt and enhance various models from a single base. This shift will enable continuous improvements across the entire product lineup, enhancing cars already in the hands of customers and speeding up the development of new vehicles.

According to Anders Bell, Volvo Cars’ Chief Engineering & Technology Officer, the Superset tech stack will dramatically improve quality, accelerate speed-to-market, and allow the brand to focus all engineering efforts in one direction, rather than spreading resources across multiple projects.

Closed-Loop Development and Core Computing

Volvo Cars has also implemented a closed-loop development process, leveraging data, connectivity, software, and advanced core computing to drive continuous improvement. This approach is as pivotal as the company’s transition to electrification, providing limitless potential for enhancing every aspect of its vehicles. Real-time insights and enhanced compute capabilities allow for an ongoing cycle of updates and refinements, improving vehicle performance, safety, and user experience.

Next-Generation SPA3 Platform

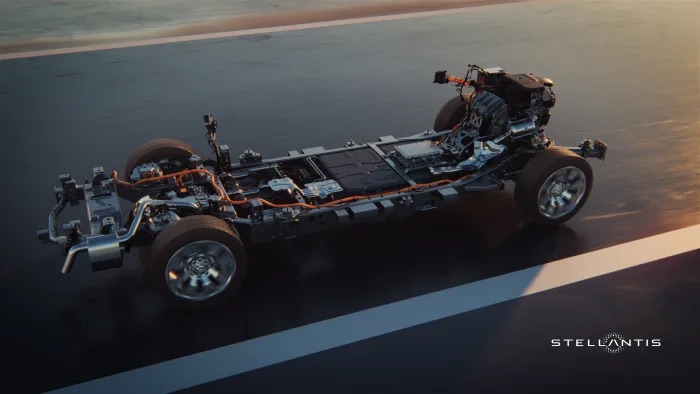

Volvo is also developing a new electric technology base, called SPA3, which will be a key building block for its future vehicles. The EX60 midsize SUV, the first car built on SPA3, will benefit from enhanced core computing capabilities, scalable architecture, and improved performance. SPA3 offers greater scalability than its predecessor, SPA2, allowing for the development of vehicles of various sizes, from small EVs like the EX30 to larger models beyond the EX90.

The modular nature of the SPA3 platform will enable Volvo to reduce production costs and increase manufacturing efficiency. This scalability will also lower investment costs, leading to stronger future cash flow and helping Volvo to maintain a competitive edge in the electric vehicle market.

Lower Production Costs and Increased Efficiency

Volvo’s Torslanda plant serves as a key example of this new approach, with preparations underway for the production of SPA3 cars. By focusing on scalability, Volvo will achieve greater synergies, improved technology efficiency, and reduced complexity in production. Key components such as core computing, batteries, e-motors, and megacasting will be used across all SPA3-built cars, driving down production costs while increasing flexibility.

Overall, Volvo’s new tech-driven strategy represents a significant leap forward in the development of next-generation electric vehicles, ensuring their cars remain cutting-edge, sustainable, and competitive in the evolving automotive landscape.