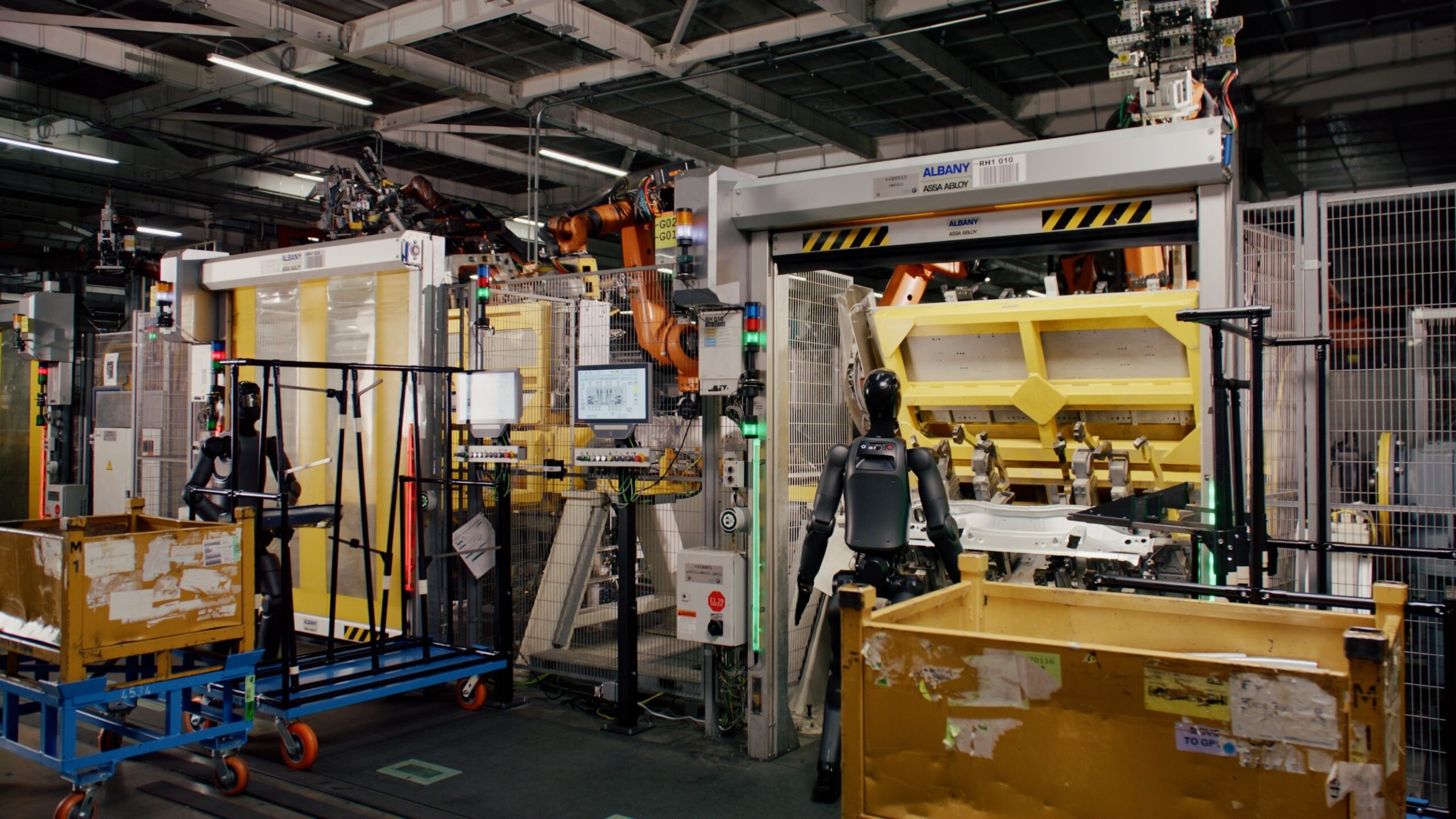

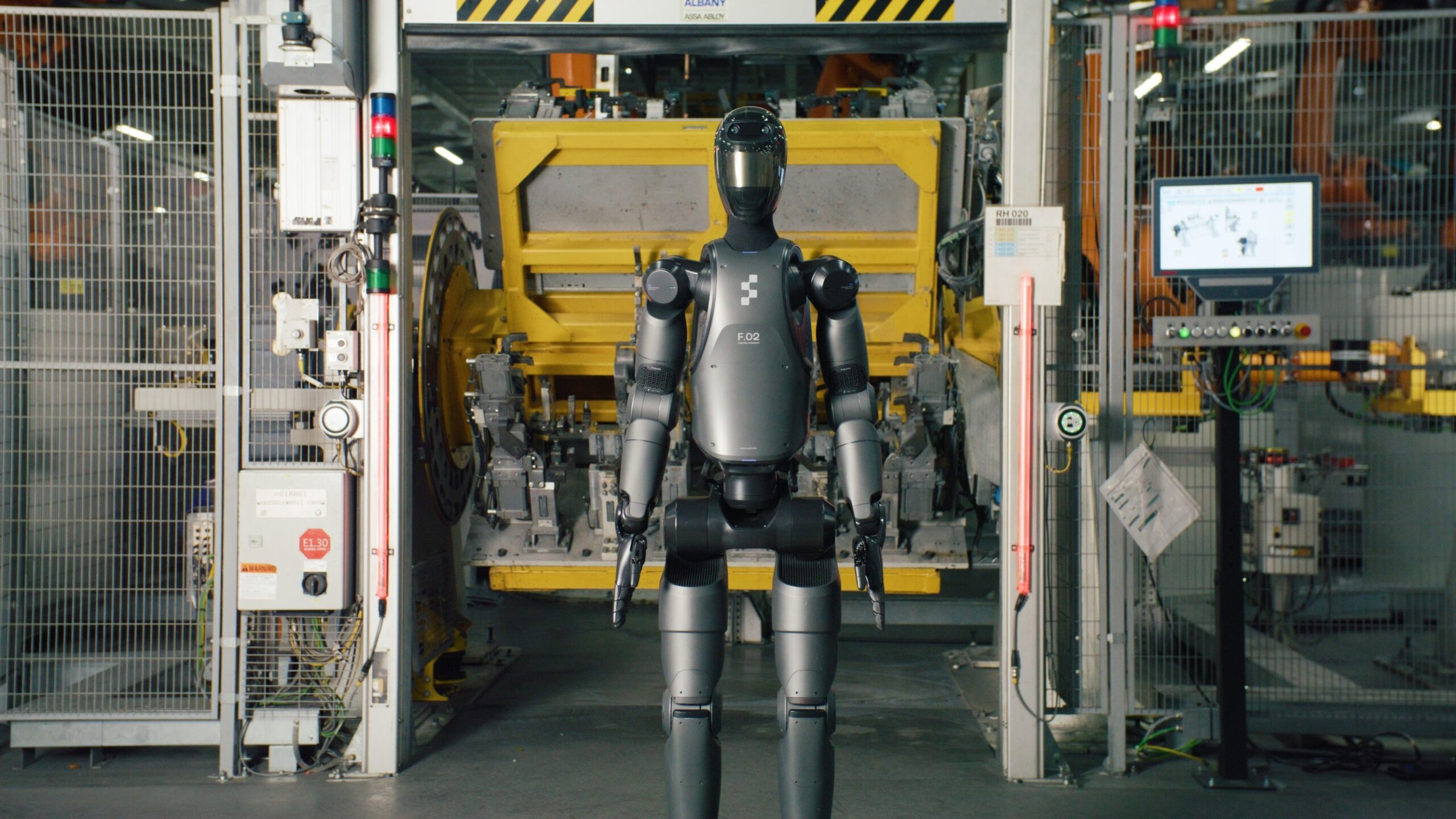

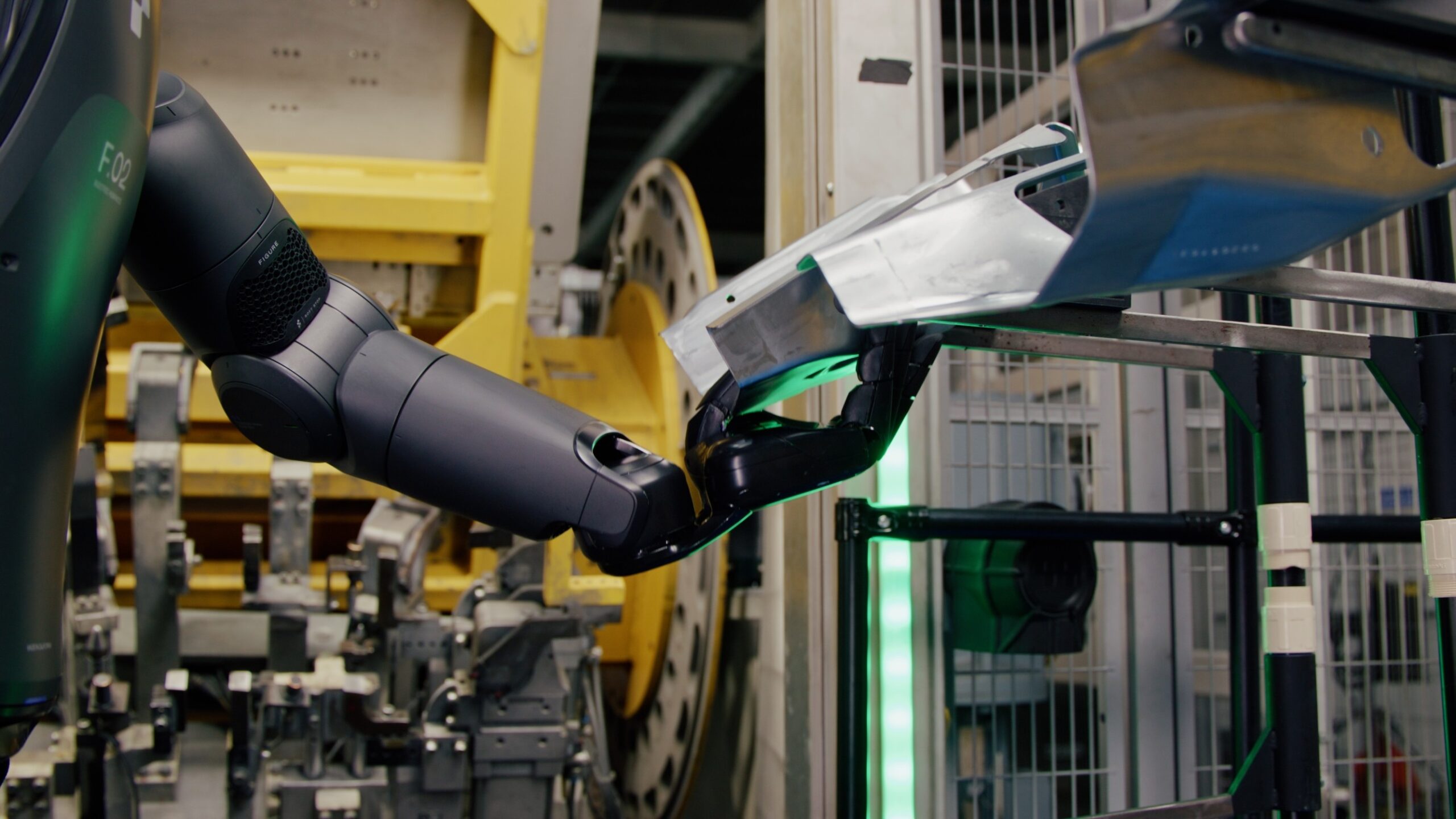

The BMW Group is venturing into a new era of automotive manufacturing by exploring the use of humanoid robots in its production processes. During a recent trial run at BMW Group Plant Spartanburg, the company tested the latest humanoid robot, Figure 02, from the California-based company Figure. This cutting-edge robot demonstrated its capabilities by successfully inserting sheet metal parts into fixtures, a crucial step in chassis assembly that requires precise dexterity.

Advancing Production Efficiency and Ergonomics

The trial, which spanned several weeks, highlighted the potential of humanoid robots to perform complex tasks that are ergonomically challenging for human workers. By automating these tasks, BMW aims to enhance workplace safety and efficiency. The collaboration with Figure focuses on evaluating how these advanced robots can be integrated safely and effectively into existing production lines.

Milan Nedeljković, Member of the Board of Management for Production at BMW AG, stated that the developments in the field of robotics are very promising. With an early test operation, they are now determining possible applications for humanoid robots in production. They want to accompany this technology from development to industrialisation.

The BMW iFACTORY vision for future production emphasises efficiency, digitalisation, and sustainability. The trial with Figure 02 provided valuable insights into the requirements for integrating multi-purpose robots into current production systems, including their interaction with existing workflows and systems.

Cutting-Edge Technology with Figure 02

Figure 02 is touted as the most advanced humanoid robot currently available. Its features include:

- Enhanced Processing Power: Three times greater than its predecessor.

- Improved Communication and Sensing: Better voice communication, cameras, microphones, sensors, and a high-performance battery.

- Advanced Dexterity: Fourth-generation human-scale hands with 16 degrees of freedom per hand and human-equivalent strength, enabling precise manipulation and complex grasping.

- Dynamic Mobility: Capable of autonomous execution of human-like tasks requiring coordinated hand movements and dynamic walking.

Future Prospects

While Figure 02 has not yet been deployed at BMW Group Plant Spartanburg, and no specific timeline for its integration has been set, BMW Group is committed to collaborating with Figure. The focus will be on data collection and further development to tailor the robots for future production needs.

The successful trial of Figure 02 marks a significant step towards the potential future use of humanoid robots in automotive manufacturing, aligning with BMW Group’s commitment to innovation and cutting-edge technology.