Toyota has taken another significant step towards its goal of achieving zero carbon emissions by unveiling a prototype hydrogen fuel cell-powered Hilux. This introduction showcases Toyota’s comprehensive approach to carbon-free mobility, exemplified by its diverse range of powertrain solutions, including hybrid electric, plug-in hybrid electric, battery electric, and fuel cell electric vehicles.

The prototype was revealed at Toyota Manufacturing UK’s Burnaston car plant in Derby, where it was developed through a collaborative effort with consortium partners, with support from UK Government funding. The Hilux, known globally as an emblematic truck within the Toyota brand, is renowned for its reliability and durability. This development project has explored ways to maintain these qualities while introducing a new electrified powertrain, underscoring Toyota’s commitment to innovation and sustainability.

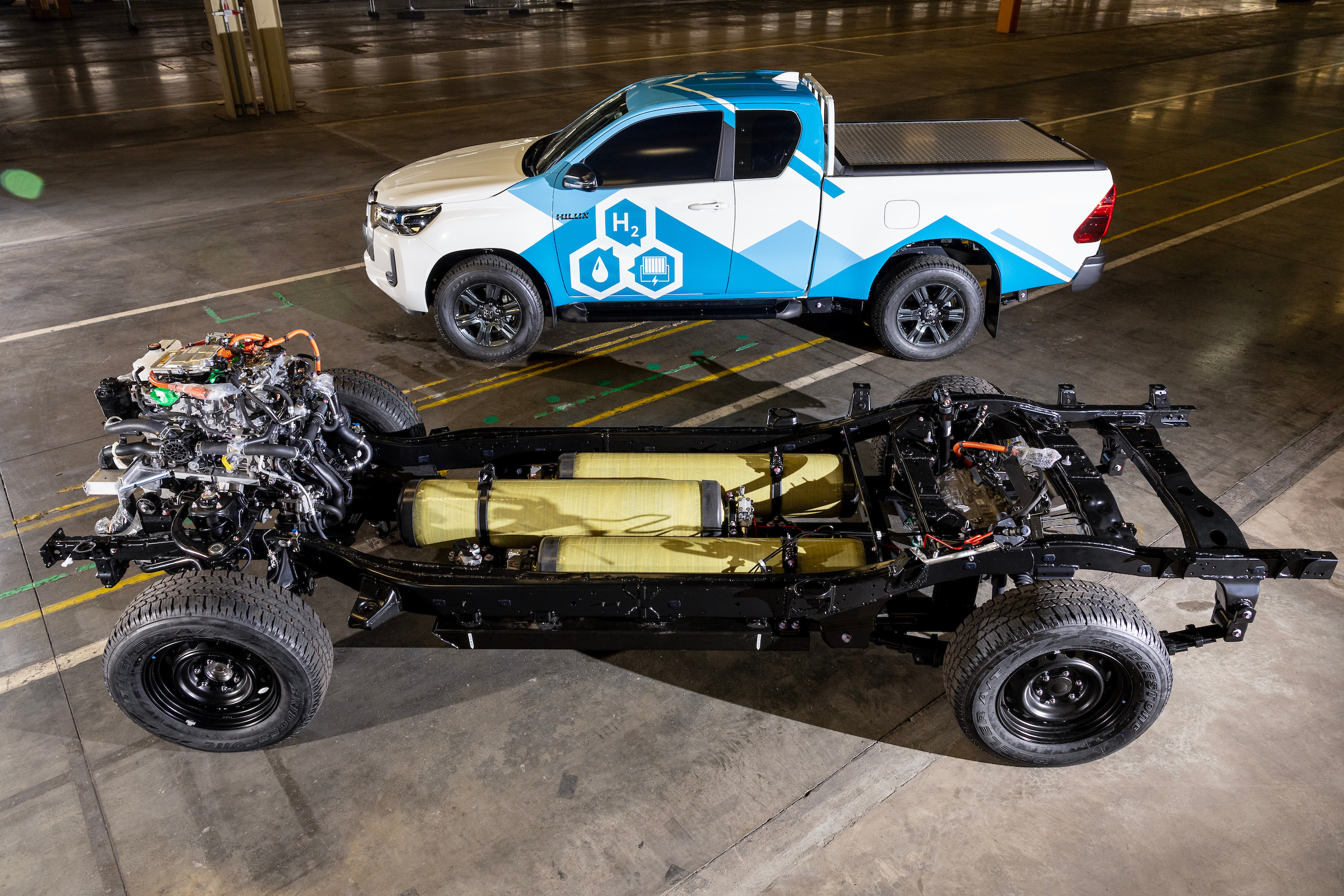

The new powertrain for the Hilux draws on essential components from the Toyota Mirai hydrogen fuel cell electric sedan—a technology that has demonstrated its reliability through nearly a decade of commercial production, which our Sarawak Deputy Premiers own. Notably, when it is in operation, the fuel cell generates zero tailpipe emissions, releasing only pure water into the environment.

To ensure an extended driving range, the Hilux incorporates three high-pressure fuel tanks. This configuration is expected to provide a driving range of more than 587km, a considerable distance compared to what can typically be achieved with a battery electric system. Additionally, the battery, which stores electricity generated onboard by the fuel cell, is strategically positioned in the rear load deck, avoiding any compromise of cabin space. This design choice enhances both practicality and usability for the truck

In early 2022, TMUK and Toyota Motor Europe teamed up with partners like Ricardo, ETL, D2H Advanced Technologies, and Thatcham Research for a feasibility study. They secured funding from the UK Government through the Advanced Propulsion Centre, a group focused on cleaner technologies. This allowed them to kickstart a focused design and development program starting on July 1, 2022, with additional support from Toyota Motor Corporation (TMC).

They began building prototypes on June 5th, following Toyota Production System principles at the TMUK facility. Surprisingly, they completed the first prototype just three weeks later. They plan to build a total of ten prototypes by the end of this year. These prototypes will undergo rigorous testing worldwide to ensure they meet the high standards necessary for a production-ready model.

This project has provided an opportunity for TMUK members to acquire and apply new skills in the realm of fuel cell electrified vehicles and hydrogen system components. The consortium members have all played integral roles in the initial phase of the program. Ricardo has actively contributed by assisting in the preparations for prototype construction, carrying out various design and development tasks, and validating the entire manufacturing process in parallel with TMUK teams. In the coming months, they will conduct a comprehensive evaluation of the vehicle.

Additionally, Thatcham Research, an automotive risk intelligence company dedicated to understanding the opportunities and risks associated with new vehicle technology, has supported the project. They have done so by offering sustainable repair consultancy and preparing hydrogen training resources for the repair market, aligning with the project’s objectives.