Toyota Motor is preparing to resume operations at its assembly plants in Japan on Wednesday. This comes after a malfunction in its production system caused a complete halt in domestic output for the world’s largest automaker.

Toyota intends to gradually recommence operations at 25 production lines situated within a dozen plants in its home market. The process will continue as the final two plants are slated to become operational again later in the afternoon of the same day.

Toyota is actively engaged in investigating the underlying cause of this production glitch. The company has clarified that the issue was not the result of a cyberattack; rather, it was a technical malfunction that affected the company’s ability to place orders for necessary components.

Approximately one-third of the automaker’s worldwide production is represented by these plants.

Toyota had been observing a recovery in its domestic production following a succession of reduced output instances attributed to semiconductor shortages. Notably, there was a substantial 29% rise in production during the period from January to June, marking the initial increase of this kind in a span of two years.

Throughout the first half of the year, the average daily vehicle production in Japan was estimated to be around 13,500 vehicles. This figure does not encompass the vehicles manufactured by the affiliated automakers Daihatsu and Hino.

Last year, there was a one-day suspension of operations due to a cyberattack on a supplier, which impacted Toyota’s capacity to place part orders. Toyota later recommenced its activities by utilizing a secondary network.

According to analysts, Toyota might face a challenge in compensating for the production that was disrupted during the outage. One potential approach could involve implementing additional shifts to make up for the lost output.

Seiji Sugiura, an analyst at the Tokai Tokyo Research Institute, mentioned, “Since the production was already operating at maximum capacity, there is limited space for further manufacturing.”

The incident on Tuesday also had a ripple effect. Toyota Industries, a subsidiary of the group, announced a partial suspension of operations at two engine plants due to the glitch experienced by the automaker.

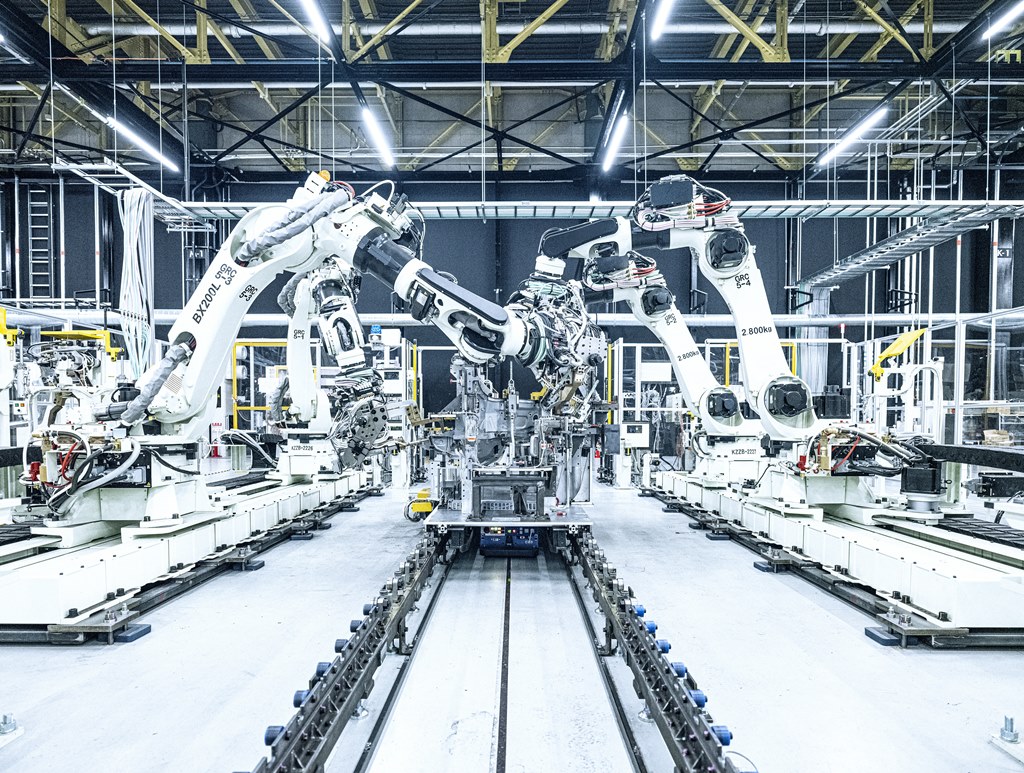

Toyota is renowned for its implementation of just-in-time inventory management, a strategy that helps control costs but leaves production vulnerable to disruptions in the supply chain.

Although the precise cause of the most recent malfunction remained unclear, businesses and government offices across corporate Japan had been on high alert lately due to reports of bothersome phone calls.

The government indicated that these calls were likely originating from China and were connected to Japan’s decision to release treated radioactive water from the damaged Fukushima nuclear power plant into the Pacific Ocean.

These factors led to Toyota’s stock price ending the day down 0.21% at 2,431.5 yen after spending a sizable portion of the morning in the red.