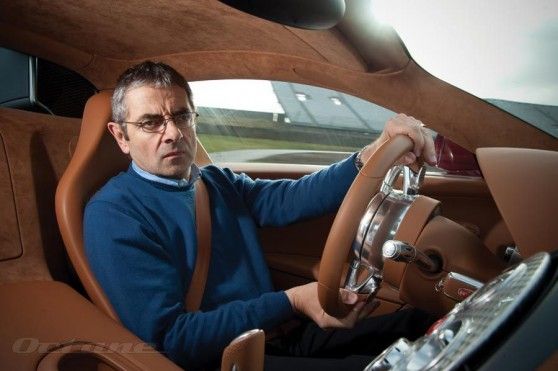

Car manufacturers are now moving towards a “greener” future by producing electric vehicles (EVs) to reduce global CO2 emissions. However, if you look beyond what comes out of the vehicle’s exhaust system, there is a bigger picture to consider, as explained by Rowan Atkinson.

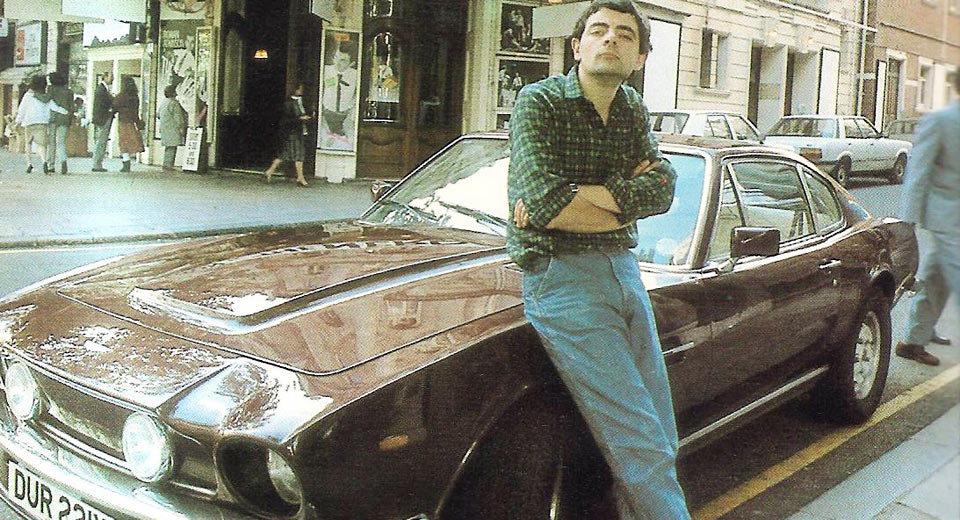

Some may already know that Atkinson is a gearhead with a degree in electrical and electronic engineering, along with a subsequent master’s degree in control systems. He has owned multiple classic and legendary cars such as the BMW 328, McLaren F1, 2002 Acura NSX-T, Mercedes-Benz SLS AMG, Aston Martin V8 Vantage (1977), and more. Initially, he had a love for EVs when he purchased his first electric hybrid 18 years ago and his first pure electric car nine years ago. However, he believes that EVs, while wonderful mechanisms, lack soul—a sentiment we wholeheartedly agree with.

Despite his initial love for EVs, Atkinson now has second thoughts about them. Upon closer examination of the facts, electric mobility doesn’t seem to be the environmental cure it’s often advertised as. Atkinson explains that when you zoom out and consider the manufacturing process of EVs, the situation becomes more concerning.

Volvo released data suggesting that greenhouse gas emissions during the production of an electric car are roughly 70% greater than when producing a petrol car. It’s not as “green” as it appears, is it? Atkinson points out that the issue lies with the lithium-ion batteries currently used in almost all electric vehicles—they are excessively heavy, require a significant amount of rare earth metals and energy to manufacture, and have a lifespan of up to 10 years. Relying on such equipment to lead the fight against climate catastrophe seems absurd.

He also mentions efforts being made to find something better, specifically solid-state batteries. These batteries should be lighter and charge more quickly than existing models, but it will take years before they become available for purchase. By that time, millions of overweight electric cars with rapidly degrading batteries will have been produced.

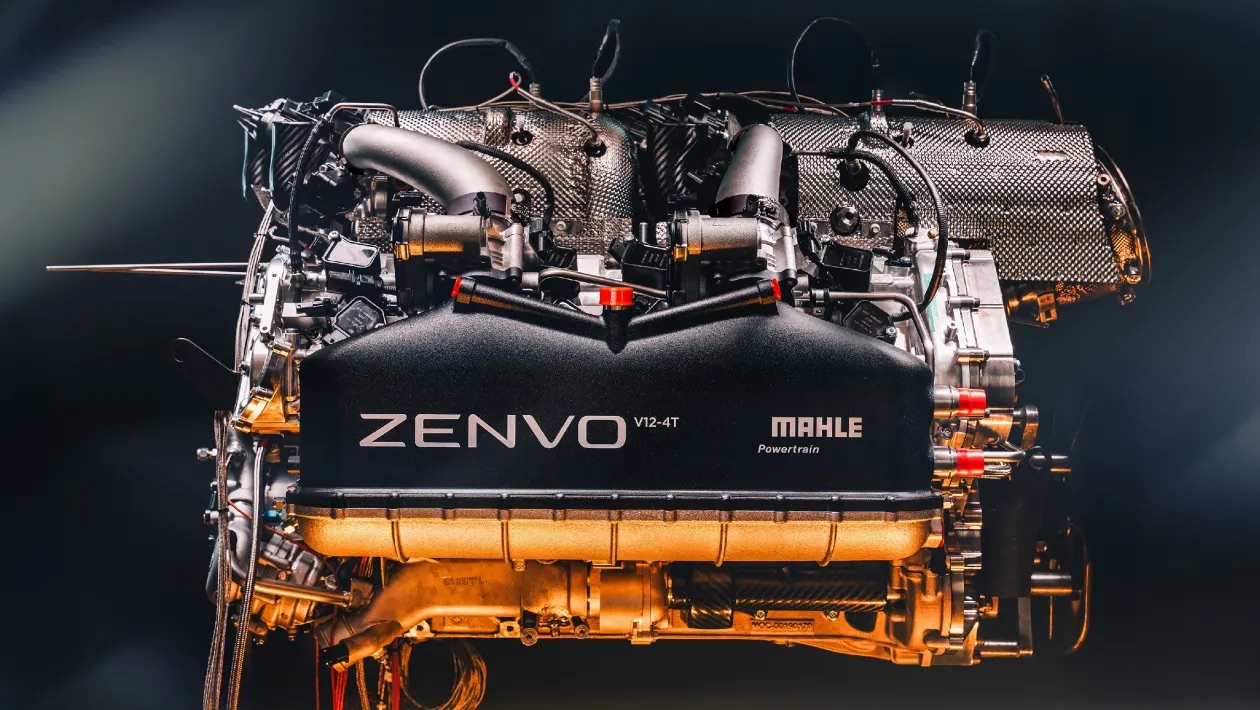

Another alternative that catches Atkinson’s attention is hydrogen, despite the fact that creating a truly “green” method of producing it is still a work in progress. Hydrogen has two possible applications; powering a hydrogen fuel cell, which is essentially a battery, and refueling automobiles with hydrogen at filling stations as quickly as with petrol. Such a system weighs only half as much as an equivalent lithium-ion battery. Toyota, one of the biggest automobile manufacturers, has invested a considerable amount of money in developing hydrogen technology.

Atkinson suggests that trucks and other heavy machines would be best suited for this alternative. He says, “JCB, the company that makes yellow diggers, has made huge strides with hydrogen engines and hopes to put them into production in the next couple of years. If hydrogen wins the race to power trucks—and as a result, every filling station stocks it—it could become a popular and accessible choice for cars.”

He feels that our “honeymoon” with EVs is coming to an end and that we must eventually face the music. It is necessary to explore wider options and continue the development of hydrogen and synthetic fuels to prevent the scrapping of older cars.

Atkinson explains that people typically keep a car for three to five years before upgrading to a newer one, which is the trend we observe today. Internal combustion engine (ICE) cars have much more potential and, with proper care and love, can run for almost 30 years.

When asked if someone should consider getting an EV, Atkinson simply says, “If your car is an old diesel and you do a lot of city center driving, you should consider a change. But otherwise, hold off for now. Electric propulsion will one day provide real, global environmental benefits, but that day has yet to arrive.”