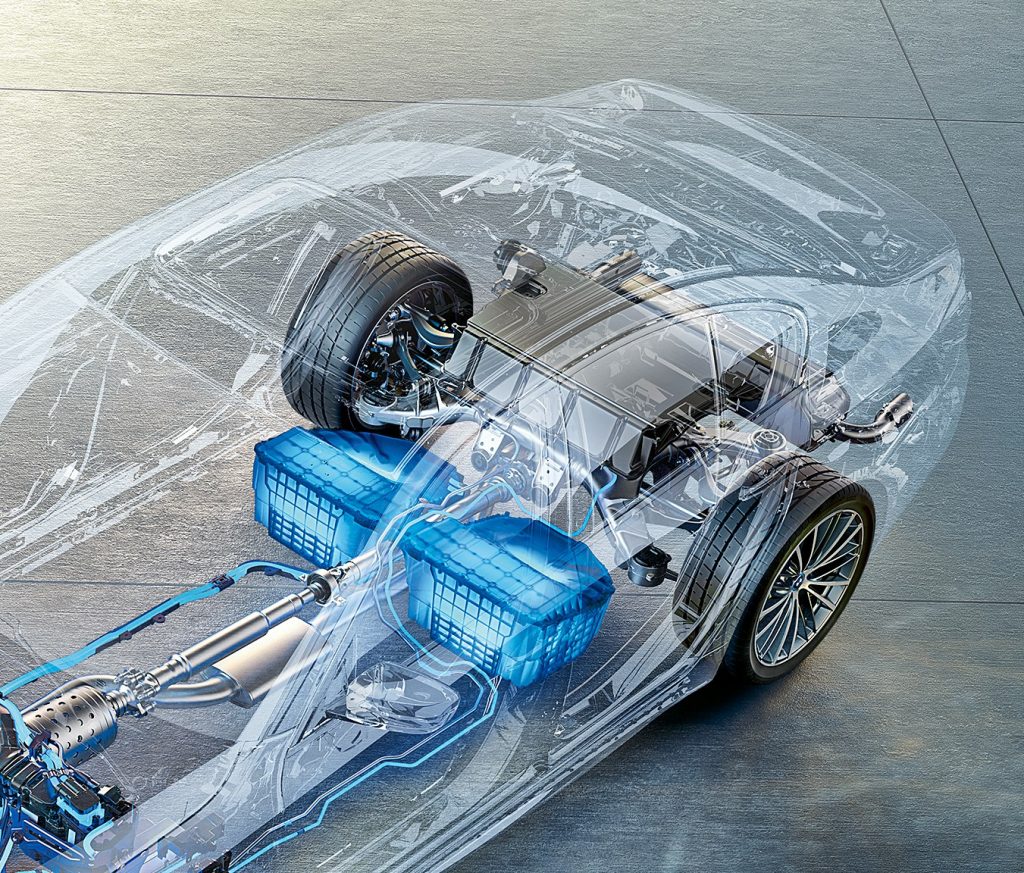

With motor vehicles becoming more electrified, fire and rescue departments have had to take into consideration the new issues of high-voltage equipment in the vehicles. Unlike the 12V battery that has been in cars for decades – mainly to provide electricity to turn the starter motor – the electrical systems in electric vehicles (EVs) run from 200V to 800V.

If the vehicle is involved in an accident and cables are disconnected or damaged, there is a danger of electricity leakage onto the bodywork. For this reason, the new generation of hybrid rallycars have warning lights to alert rescuers and spectators of any electrical danger if the car crashes. Latest regulations even require the crew to have available Class-0 gloves carried capable of withstanding 1,000 volts.

Electricity leakage is one danger and some car companies have taken the initiative to train fire departments on how to safely deal with an EV involved in an accident, with guidance and information on cutting off the power supply.

When the battery pack is burning

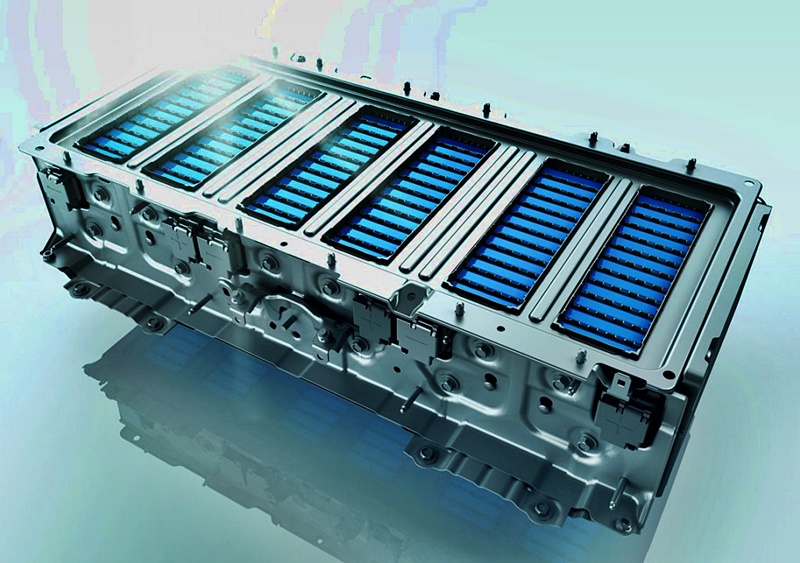

The battery pack is also another area of concern and today’s lithium-ion type can be far more serious and difficult to extinguish. Once a battery pack has been damaged by an accident or external fire, it can be difficult to tackle the resulting blaze as the energy contained with the cells is released, causing a ‘thermal runaway’.

Previous ways of preventing this or fighting the fire involve extreme measures such as immersing the entire car in water for days in large bags or shipping containers. But this may not always be [possible, especially if in an enclosed space such as an underground or multi-storey carpark.

A new, more practical way of tackling such situations has been developed along with a new rapid intervention vehicle which can deliver the crew and equipment to locations where height may be limited, such as car park structures.

Lessons learnt

This, in combination with traditional firefighting techniques, can help prevent large fires escalating such as the recent incidents at Kings Dock carpark in Liverpool, England, and Stavanger Airport in Norway. In those cases, none of the large fire and rescue vehicles were able to enter the structures in the early stages of the fire due to height restrictions.

By the time crews entered on foot with fire-fighting equipment and water, the fire had developed beyond control. The resulting devastation led to thousands of cars being destroyed, an airport and then closure followed by costly re-building.

Toyota Hilux-based vehicle

The basis of the Rapid Intervention Vehicle is the British-built HILOAD, engineered by Prospeed Motorsport in England. Its engineering-led approach uses a Toyota Hilux as a base vehicle, fitted with an entirely new chassis to avoid a compromised ‘cut and shut’ of the original frame.

he Rapid Intervention Vehicle is the British-built HILOAD, engineered by Prospeed Motorsport in England. Its engineering-led approach uses a Toyota Hilux as a base vehicle, fitted with an entirely new chassis to avoid a compromised ‘cut and shut’ of the original frame.

With the replacement chassis and a torque splitter system, the 6×6 has rated 5,600 kg Gross Vehicle Weight, which allows 3,000 kg payload. That’s almost triple the standard 4×4 Hilux’s capacity, and the load-space is also extended by 1230mm.

Although longer, the HILOAD’s height is just 1850mm – less than some large SUVs and low enough to allow access to the majority of parking structures. It also results in a lower centre of gravity and better stability in high-speed manoeuvres which may be necessary when rushing to the scene.

Coldcut Cobra system

Among the other equipment which the increased payload helps carry, the HILOAD can be fitted with the Coldcut Cobra system for extinguishing EV battery fires. This uses the Cobra Ultra High-Pressure Lance system with an abrasive suspended in water to pierce a hole through floorpans and inject water at 300 bar – more than 100 times the pressure of the air in a typical car tyre – throughout the module casing . This water cools directly inside the battery and thus prevents propagation and further possibility of a thermal runaway.

Unlike alternatives which involve pumping thousands of litres of water into a burning vehicle in an attempt to cool the whole battery, independent tests from the Swedish Civil Contingencies Agency showed the Coldcut Cobra system could prevent cell propagation within 10 minutes, using just 240 litres of water, That’s less than a bath-full and 20% of the HILOAD’s tank capacity.

Away from urban car park environments, the enhanced traction and reduced ground pressure resulting from a 6-wheel drive set-up can also prove invaluable for tackling fires in remote and challenging environments such as forests and heathland. The HILOAD can get to these fires faster while carrying more crew, water and equipment into wild terrain.

A HILOAD is currently being trialled in the Czech Republic, with the vehicle specifically developed to tackle EV battery fires and assist with fast response occupant extraction. It is already part of one EV car manufacturer’s firefighting fleet.