Electric vehicles (EVs) are slowly coming down in price and many manufacturers believe that, by the end of this decade, they should be able to offer EVs at the same price as models with combustion engines, size for size. Economies of scale come into play, reducing the costs in many areas and also the technologies.

However, the thing that still makes people hesitate in switching to an EV is how far they can go on a fully charged battery pack. It’s known as ‘range anxiety’ and it’s understandable that motorists worry about being stranded somewhere when their battery pack is empty.

Of course, combustion engine cars can also run out of fuel if the driver is not mindful of the amount remaining in the tank. But the difference is that you can probably call for help and someone can bring fuel to pour into the tank, or even get a life to a nearby town to buy fuel and come back. And there are petrol stations all over – unlike the limited (but slowly growing) network of recharging stations.

Apart from the network of charging points, there are also issues of charging time which are longer than an average fill-up of a petrol or diesel fuel tank. Some may find it an inconvenience and others may not but the fact remains that you do have to factor in time spent waiting for the battery pack to get fully or almost fully charged. It’s one of those things that you’ll have to accept with the ‘EV lifestyle’.

So battery technology is a key area which needs to be advanced, both in terms of range as well as reducing charging times. At present, the newer models can be recharged to around 80% in less than an hour with DC fast-chargers. If you use AC chargers with a lower power supply, then it can be an overnight exercise.

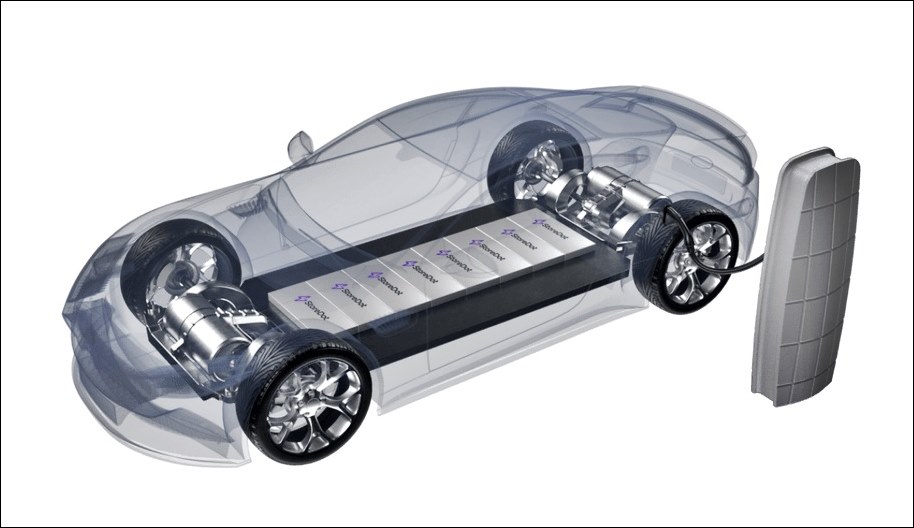

StoreDot is one of the companies that has developed new battery technology which will make battery packs cheaper and lighter and more importantly, quicker to recharge. Their extreme fast charging (XFC) battery technology is used in silicon batteries which will soon be in commercial production.

Basically, what StoreDot has done with the battery chemistry is to replace the traditional lithium-ion graphite anode with its patented bio-inspired active-material nanoparticles which are synthesized together with proprietary small-molecule organic compounds. These accelerate ion diffusion, for proven quick, safe, and stable charging while also addressing issues of energy fade and preeminent rate capability limitations.

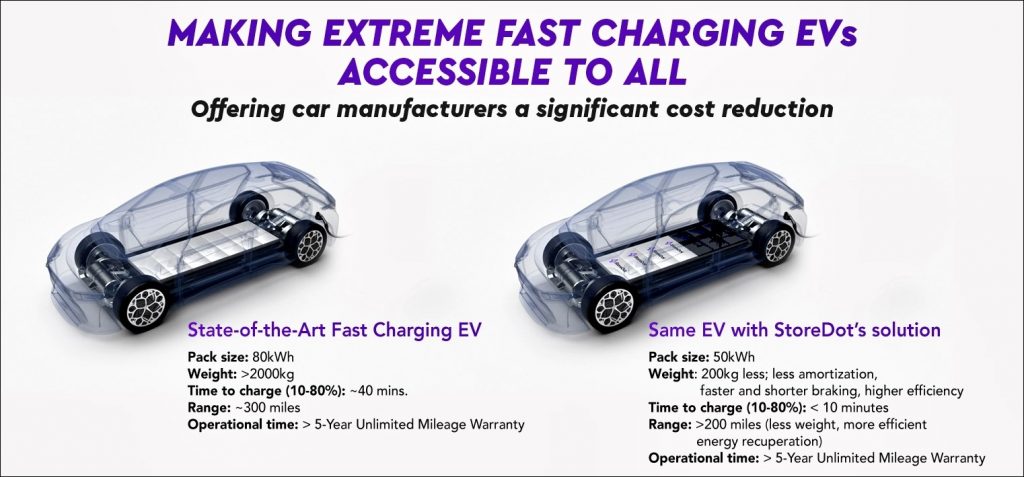

This new technology will enable battery packs to be smaller, reducing vehicle weight, and yet have useful storage capacities. Smaller packs with XFC translate into improved EV specifications including better operating efficiency, increased utilization of regenerative braking, reduced carbon footprint and lower costs. As a result, more affordable EVs will help in the adoption and transition to EVs.

Downsizing from an average premium vehicle requiring an 80 kWh to a 50 kWh battery pack could save approximately 200 kgs from the EV’s weight (the equivalent weight of 3 – 4 people), Storedot estimates that this could reduce the build cost of the EV by US$4,500 (almost RM20,000), depending on metal cost fluctuations and energy density improvements.

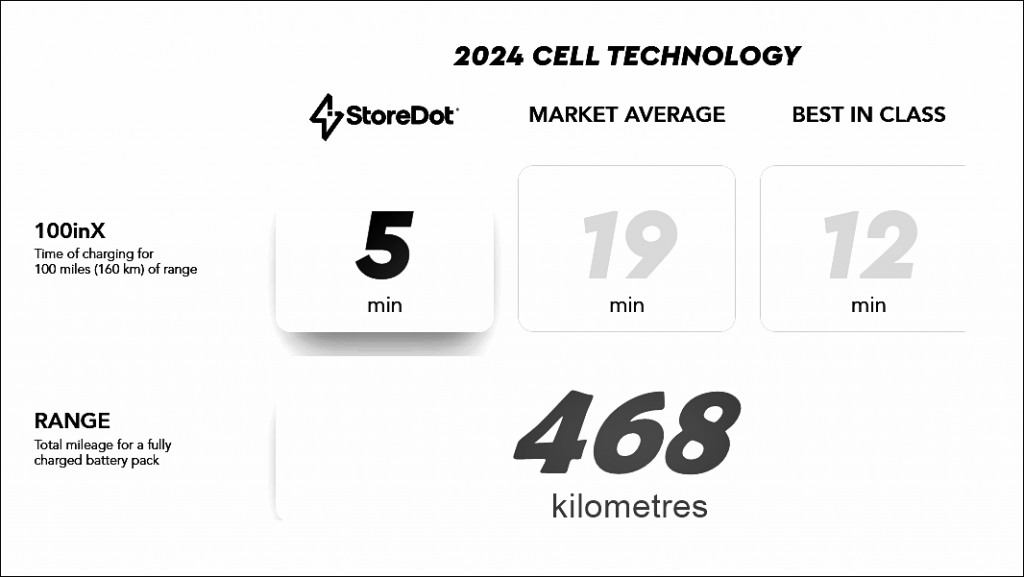

The transformative technology will make it possible to ‘fill up’ with electricity for 160 kms of travelling range within 5 minutes. Double that time – 10 minutes – and you could get enough range from the battery pack to driver from Kuantan to the Klang Valley, with some reserve to be on the safe side.

This can change how people use and recharge their EVs, with less concern about range. Carmakers will be able to re-evaluate the specifications of EVs, optimizing weight and cost, rather than pushing for greater range with larger battery packs.

“The two remaining barriers to EV ownership are charging anxiety and cost, and StoreDot’s XFC solution was designed to assist with both. Radically reduced charging times will allow automotive manufacturers to rethink how they approach battery size and range. When charging times are no longer an issue, it makes a lot more sense to fit smaller battery packs. The cost-savings could transform the accessibility of EVs and sustainability of batteries, with better car efficiency, fewer raw materials needed and less recycling at the end of their in-vehicle life,” said Dr. Doron Myersdorf, CEO of StoreDot.

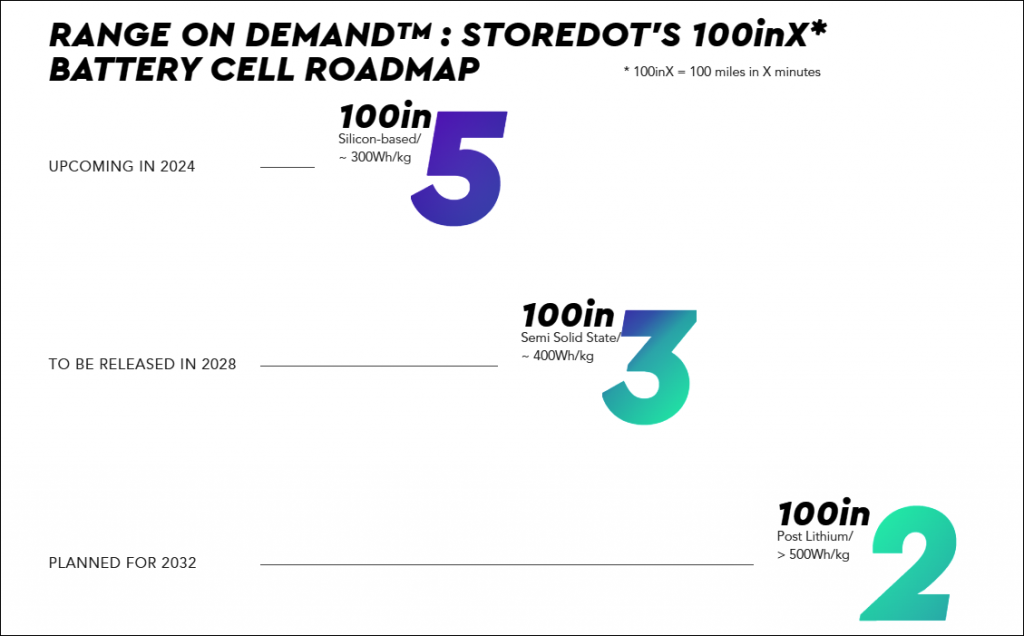

StoreDot’s XFC battery cells are now being tested by over 15 global automotive manufacturers, with mass production readiness of XFC silicon battery cells ready by next year. The first generation will be designated ‘100in5’ with 300 Wh/kg and 100 miles (160 kms) in 5 minutes. The second generation will be ‘100in3’ and be semi solid-state with a density of 400 Wh/kg and 100 miles in 3 minutes. By 2032, with post-lithium chemistry, the third generation ‘100in2’ is expected to be available with 500 Wh/kg and 160 kms in just 2 minutes.