For many decades, when writing about Rolls-Royce cars, motoring journalists would mention Crewe, the location in England where they were made since 1946. However, Crewe’s association with Rolls-Royce would cease (and become associated with Bentley) after 2002 when the BMW Group acquired full ownership of all elements of the Rolls-Royce brand in 2003.

This development meant that BMW had to provide Rolls-Royce with a new home, certainly in England, and a brand new factory was built at Goodwood in Sussex with an initial investment of £65 million. The site was meaningful as it was just about 15 kms from where the company’s co-founder, Sir Henry Royce, lived and worked for the last 16 years of his long and illustrious life.

Conscious of the significance of the brand and its position at the pinnacle of the auto industry, BMW wanted the new factory to be as innovative and technologically advanced as the products that would be created inside. To design the Home of Rolls-Royce, the company commissioned architects Nicholas Grimshaw & Partners, whose credentials included London’s Waterloo International railway station and the Eden Project in Cornwall.

Blending into the landscape

The architects created a striking, contemporary and highly sustainable building that blended effectively into the surrounding landscape. The main manufacturing building was laid out on a 20 metre x 20 metre grid, with steel columns supporting roof lights 8 metres in diameter. Windows running the length of the assembly area – the so-called ‘glass mile’ – allowed natural light to flood in, and also give visitors a view of the entire production line.

The building was planned to be 2 storeys high, rising up to 10 metres. However, before construction began, around 80,000 tonnes of gravel were extracted from the site. This enabled the plant to be a couple of metres below the surrounding ground level. Combined with the 3.5-hectare curved sedum ‘living’ roof, this helps the building ‘disappear’ into the landscape. Other methods of blending in a region referred to as an ‘Area of Outstanding Natural Beauty’ included having 400,000 plants and over 120 species of trees, as well as limestone and cedar cladding on the buildings.

There’s also a large central lake, which attracts numerous wild birds, acts as a heat sink for the plant’s climate-control systems, providing drastic cost and energy savings over air-conditioning. It also forms a vital part of the Sustainable Urban Drainage System water management system, storing filtered runoff from the roof and carparks before allowing it to drain naturally into the ground, preventing flooding.

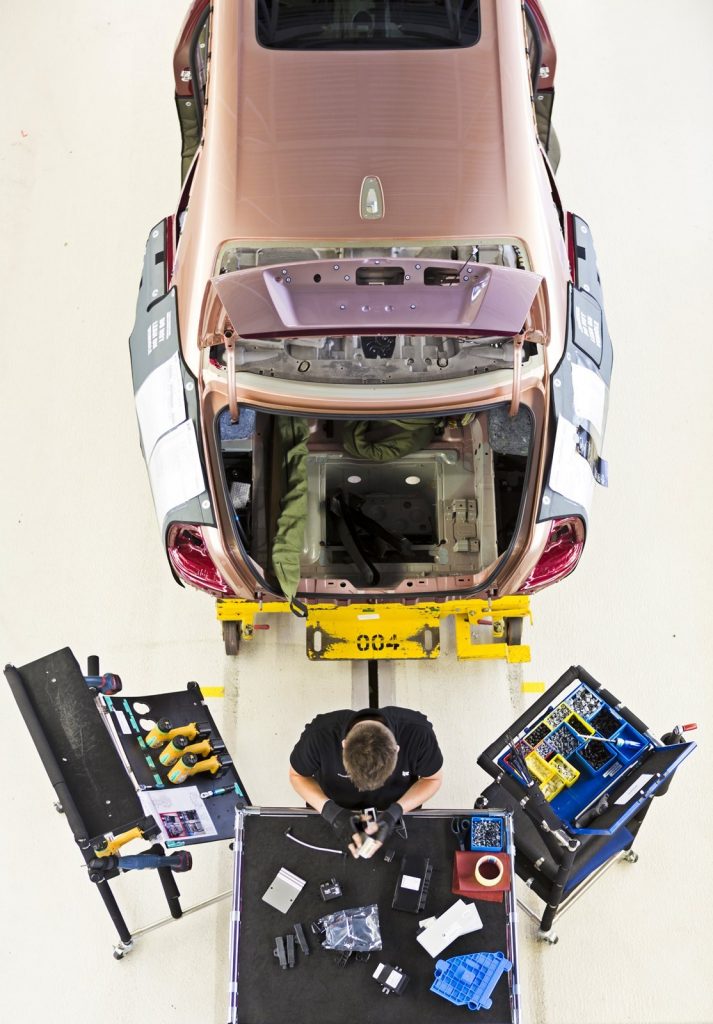

There’s also a human side to the story of the Goodwood factory and that is about the people at the Home of Rolls-Royce. In 2003, there were just 350 people and this number has grown to 2,500 today, with 150 new posts created in 2022 alone. More than 50 nationalities are represented among the designers, engineers, craftspeople, assembly teams, sales, marketing, finance, IT, human resources and other specialists

The first Goodwood model

The factory took about 2 years to complete and was already making its first model – the seventh-generation Phantom – in the closing months of 2002. The first completed unit was handed over to its new owner in a special ceremony at exactly one minute past midnight on January 1, 2003. Since that historic moment, no fewer than 20 different models and variants have been created at Goodwood – equivalent to one for every year.

The Phantom, and its derivative Phantom Drophead Coupe and Phantom Coupe, were followed by the Ghost, which went on to become the best-selling model the brand has ever produced since its foundation in 1904. The product family grew further with the Wraith (2013) and Dawn (2016), and then, in 2018, came the Cullinan, the first SUV from Rolls-Royce.

Always the pioneer

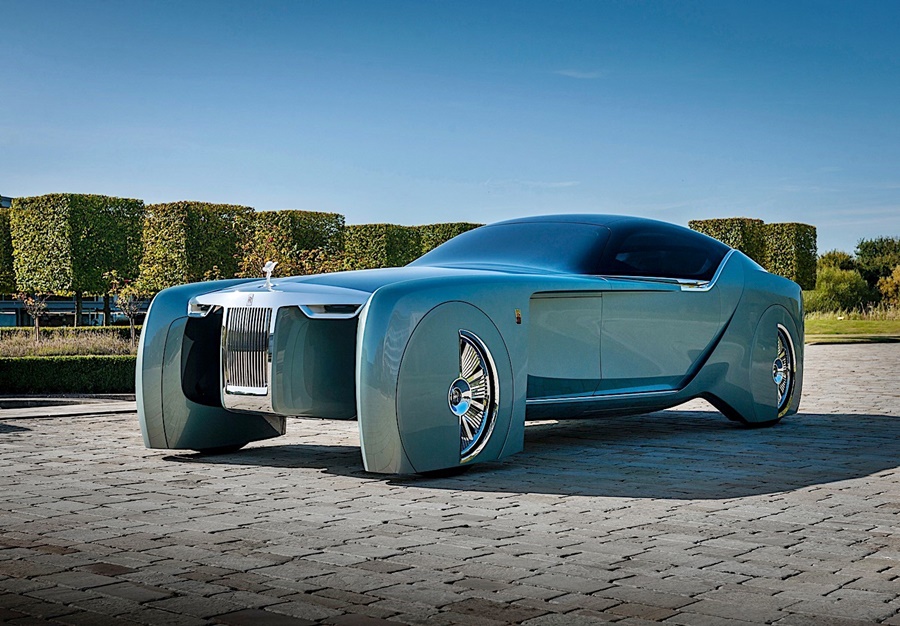

Rolls-Royce has also been pioneering in many ways and its design and engineering teams have produced a number of experimental vehicles over the past 20 years. Many may have never been known to the outside world but those that were revealed had an ‘EX’ designation and a distinctive red-on-silver badge. Never intended for production, they were fundamental to the process of creating some of the most technically significant and commercially successful products in the marque’s history.

The first 20 years at Goodwood have culminated in the launch of Spectre, the first all-electric Rolls-Royce ever made for sale. It marks the beginning of a new technological era in which every new Rolls-Royce model will be fully electric from 2030 onwards.