Over the many years it has been in business, Lotus Engineering, the consultancy division of Lotus, has done work for many carmakers and in most cases, the scope of their work has been confidential. Of course, enthusiasts would know that vehicle dynamics is a speciality of the company so it’s not difficult to guess the areas that they would have been involved in.

There have been some models where the Lotus name has been associated with the product – like the Lotus Cortina, Lotus Sunbeam and Lotus Carlton/Omega. These were high-performance cars that were developed, engineered and manufactured in partnership with Ford, Talbot and GM, respectively.

All three models were successful for both the companies concerned and for Lotus, enhancing brand images as well as building a reputation in the world of motorsport. The Cortina, for example, won multiple touring car championships while the Sunbeam took the Manufacturers’ title in the 1981 World Rally Championship.

In the late 1990s, the Vauxhall Astra proudly advertised the association, with ‘Handling by Lotus’. The 2015 Hyundai Genesis was another car that acknowledged involvement of the British company, with the lead vehicle dynamics engineer from Lotus even joining in the media launch activities in the USA. A few cars have even carried a ‘Handling by Lotus’ badge, among them the Isuzu Piazza and the Proton Satria GTI.

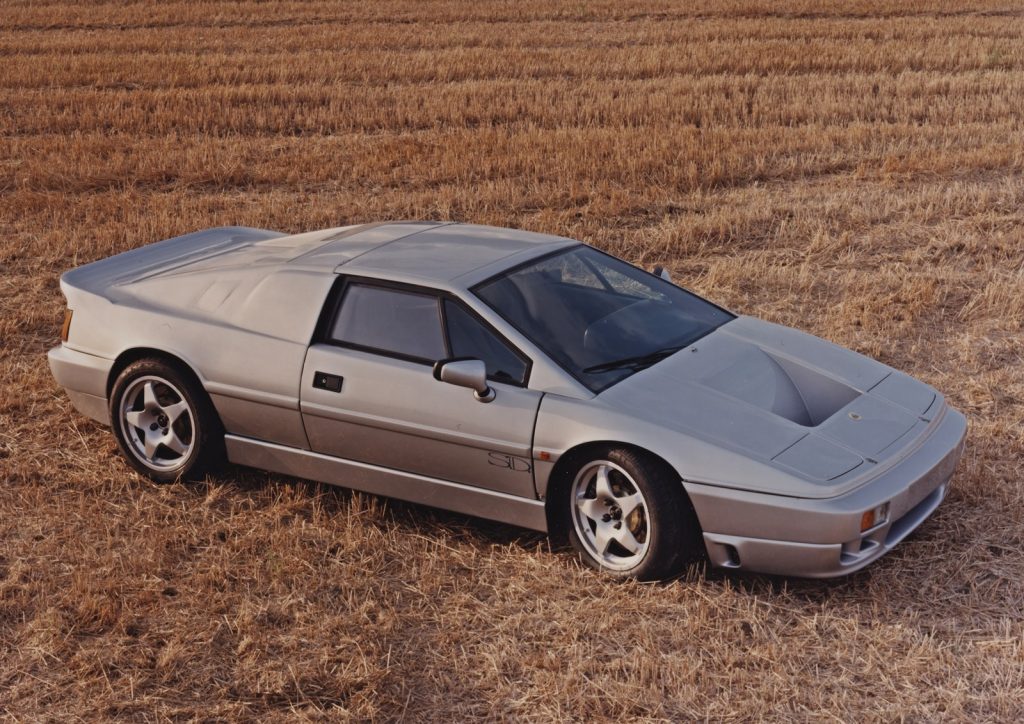

In 1992, another Lotus Engineering dynamics project which was publicised was Structure, Isolation and Dynamics Research – better known as SID. It was an amalgamation of two engineering groups, bringing together their expertise to reinvent ride and handling development.

A composite monocoque with Esprit bodywork (the Structure) sat on a unique backbone chassis supporting a 300 bhp turbocharged V6 MG Metro 6R4 powertrain (through various tuneable elements, the Isolation). It was a technical tour de force – a rolling testbed for Lotus-developed active suspension, active ride, 4-wheel steering and 4-wheel drive (the Dynamics).

Clever algorithms meant it could showcase each of its technologies one at a time or all together, and SID included a digital controller which meant every suspension parameter could be modified at the touch of the laptop keyboard, even while on the move. That in itself was an achievement, for the first time enabling the data to be captured and downloaded for further analysis.

Importantly, it allowed the SID team to plot dynamic inputs against driver experience – what was it that created ‘that special feeling’ in the person behind the wheel? – which was crucial to improving dynamic understanding for clients of the Lotus Engineering consultancy, but also the carmaker itself.

Today, this is part of the many decades of learning which have influenced what the company knows about active and passive systems. The 5-link suspension at the rear of the Eletre Hyper-SUV launched earlier this year is a great example of that progression.

Featuring multi-chamber air suspension with continuous damping control, a 48V anti-roll system, torque vectoring and an active rear axle (depending on model) with a selection of drive modes, it integrates dynamic excellence into a completely new class of Lotus vehicle.

“At Lotus, we’ll never use electronics as a ‘sticking plaster’ for a poor architecture or chassis, but we can make a vehicle like the Eletre feel as nimble as the Elise because we understand technologies such as rear-wheel steering, active roll control and active damping,” said Gavan Kershaw, Director of Vehicle Attributes.

Lotus Engineering today provides comprehensive consultancy services to many of the world’s carmakers as well as Tier 1 suppliers. It is internationally recognised for its long-standing contribution to ground-breaking engineering and innovative vehicle development. The 4 core pillars of its expertise and its commercial offering are Platforms, Control Systems, Dynamics and Technical Services. The latter includes intelligent design, product concept development, attribute development, advanced engineering and even whole-vehicle manufacturing.