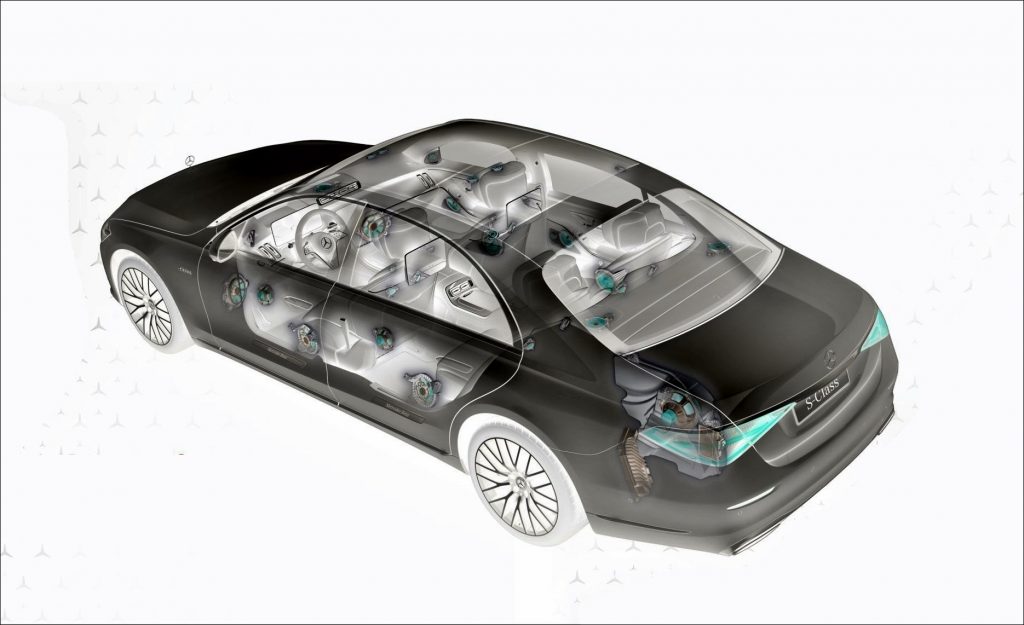

Space is at a premium in a car’s passenger compartment and interior designers have to find ways to install the various features and equipment. It doesn’t help that over the years, more and more equipment has been introduced and with audio equipment, the number of speakers has increased for what used to be just two to a double-digit number. For example, a Mercedes-Maybach with a Burmester system can have up to 27 speakers.

The specialist audio system companies have been constantly advancing their technologies as well as the designs so the dimensions of speakers have become more compact, allowing them to be more easily and discreetly integrated in panels around the cabin.

However, weight is still an issue and while each speaker is not really heavy, a number of them (especially with magnets) can add weight. Ten speakers could add up to 40 kgs, although tweeters might be insignificant in this respect. And there is still the physical thickness which needs to be accommodated but this too could see a reduction in future.

Engineers at MIT (Massachusetts Institute of Technology) in America have now developed a loudspeaker that can turn any surface into an active audio source. About the size of a hand, it is paper-thin and weighs about as much as a coin! It will generate high-quality sound no matter what surface the film is bonded to, while using a fraction of the energy required by a traditional loudspeaker.

The innovation does not actually require sophisticated technology as the researchers pioneered a simple fabrication technique. It requires just three basic steps and allows for sizing of the ultra-thin speakers to suit any surface, be it a trim panel in a car’s cabin or even mounted on a picture frame. The speakers can also be used for active noise cancellation to reduce ambient noises. They can generate soundwaves of an opposite phase to cancel out the disturbing noises.

Low energy requirement

While the speakers are said to produce high-quality sound, they only require such a small amount of power to operate. The energy-efficient device only requires about 100 milliwatts of power per square metre of speaker area. By contrast, an average home speaker might consume more than 1 watt of power to generate similar sound pressure at a comparable distance.

Along with being very light (just 2 gms), these are attributes which will be well suited for electric vehicles (EVs) where minimising weight is very important and also keeping the draw on electricity by ancillary devices to a minimum.

“It feels remarkable to take what looks like a slender sheet of paper, attach two clips to it, plug it into the headphone port of your computer, and start hearing sounds emanating from it. It can be used anywhere. One just needs a smidgeon of electrical power to run it,” said Vladimir Bulovic, the Fariborz Maseeh Chair in Emerging Technology, leader of the Organic and Nanostructured Electronics Laboratory (ONE Lab), Director of MIT.nano, and senior author of the paper describing the innovation.

A new approach

The researchers developed their innovative speaker by taking a different approach to how sound is generated. Conventional speakers use electric current inputs that pass through a coil of wire which generates a magnetic field to move a speaker membrane. This membrane then moves the air above it to create sound.

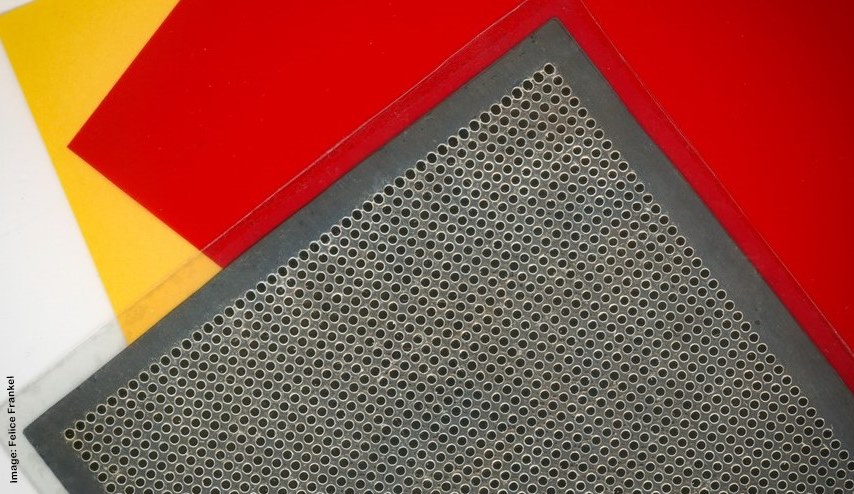

The new speaker uses a thin film of a shaped piezoelectric material that moves when voltage is applied over it. The material can also move the air molecules over it and this generates sound. To construct the speaker, the researchers used a laser to cut tiny holes into a thin sheet of PET, a lightweight plastic commonly used for containers. They laminated the underside of that perforated PET layer with a very thin film (8 microns) of piezoelectric material, called PVDF. Then they applied vacuum above the bonded sheets and a heat source, at 80 degrees C., underneath them.

Because the PVDF layer is so thin, the pressure difference created by the vacuum and heat source caused it to bulge. The PVDF can’t force its way through the PET layer, so tiny domes protrude in areas where they aren’t blocked by PET. These protrusions self-align with the holes in the PET layer. The researchers then laminate the other side of the PVDF with another PET layer to act as a spacer between the domes and the bonding surface.

Can be simple to manufacture

“This is a very simple, straightforward process. It would allow us to produce these loudspeakers in a high-throughput fashion if we integrate it with a roll-to-roll process in the future. That means it could be fabricated in large amounts, like wallpaper to cover walls, cars, or aircraft interiors,” said Jinchi Han, lead author of the paper which will appear in the January 2023 issue of IEEE Transactions on Industrial Electronics.

The research work is funded, in part, by the research grant from the Ford Motor Company and a gift from Lendlease, Inc. With proof of concept demonstrated, the ultra-thin speakers should attract the attention of manufacturers in various industries, including the automotive industry, and eventually lead to commercialisation. Certainly, such speakers would be a revolution in the audio industry.