Car designers have long turned to the aeronautical industry for ideas that have led to innovations. In particular, the shapes of car bodies have been heavily influenced by aircraft because of the pursuit of airflow efficiency. Features today like spoilers and rear wings have their origins in aircraft design although with ‘reversed’ effects where instead of lift, the objective is to gain downforce.

For high-performance sportscars, downforce is important to keep the car as stable as possible at high speeds. This has seen all types of rear wings being installed, some very ‘distinctive’ though with questionable benefits. However, for a new rear carbonfibre wing that was developed for the Lexus LC Coupe, the company formed a long-term collaboration with world champion air race pilot Yoshihide ‘Yoshi’ Muroya to gain advances in aerodynamics that would enable them to design the rear wing.

Long and unique collaboration

Since 2016, Lexus has been reaching for the skies in a unique collaboration with Muroya, winner in 2017 of the Red Bull Air Race World Championship series. In this rare cross-industry partnership, the carmaker benefits from aeronautic technology while the air race pilot leverages Lexus’ automotive breakthroughs.

With the principal aim of winning air races, Lexus and Muroya worked together to develop championship-winning aircraft using the technology, craftsmanship and experience from Lexus. The Lexus design and engineering team has helped develop flight technologies in areas such as aerodynamics, cooling and ergonomics.

The collaboration has produced notable innovations, including a control column grip for Muroya’s cockpit that incorporates Lexus’ sensitivity technologies and a new turning manoeuvre for the aircraft based on aerodynamic data from Lexus.

The new rear wing

For 2022, the Lexus LC will sport a new carbonfibre reinforced plastic rear wing developed together with Muroya. This lightweight, highly rigid and sleek wing maximises aerodynamic performance and makes for more agile driving.

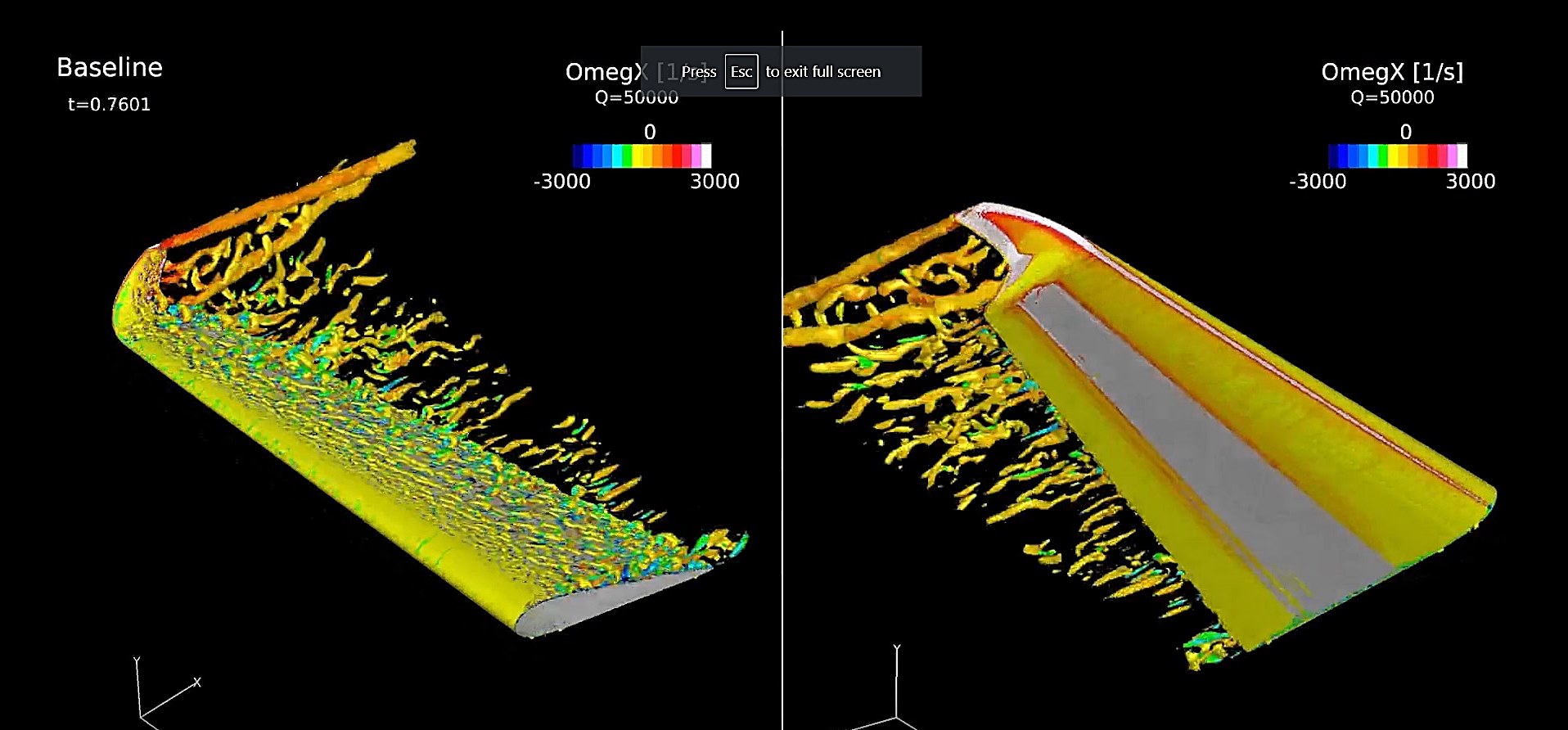

The design draws its inspiration from the wing-tip vortices that influence the design of winglets on jet aircraft. During demanding test flights with Yoshihide Muroya, Lexus engineers analysed his plane’s drag-reducing winglets and the associated vortices that are normally problematic. In the Lexus wind tunnel, engineers found that vehicle dynamics on the ground could be improved by turning the wing upside down and adding winglets.

Once computer and wind tunnel tests were completed, Lexus’ elite team of designers, engineers and Takumi artisans set to work milling an aluminium prototype. Like Muroya’s race plane wings, it was later produced in carbonfibre reinforced plastic (CFRC). Laminated in carbonfibre and epoxy resin with a hollow core, after baking in an autoclave, the woven texture is visible through the lacquered finish.

Downforce without performance loss

Long and lean, the LC’s new wing is nearly 2 metres wide, yet very durable and warp resistant. According to Lexus Takumi master driver, Yoshiaki Ito, the winglets sharpened the LC’s handling, but without using drag-creating downforce, resulting in better performance without sacrifices. The Lexus team called the car the LC Special Edition Aviation, to highlight the background to the development of the rear wing.

The carbonfibre rear wing spoiler is available (in limited numbers) exclusively with the new Lexus Bespoke Build programme. This is a special personalisation programme for customers buying a LC or LC Convertible. The vehicle will be built by an elite team of ‘Takumi’ master craftspeople at the and such units will be distinguished with a personalised interior badge installed on the centre console.