During the 1980s, Nissan was among the early Japanese carmakers to begin setting up overseas plants – not plants merely assembling cars but full-fledged factories that carried out the almost all the manufacturing processes. As the brand was very popular in Europe, the company decided to establish a factory there and after considering a few countries, it settled on Britain.

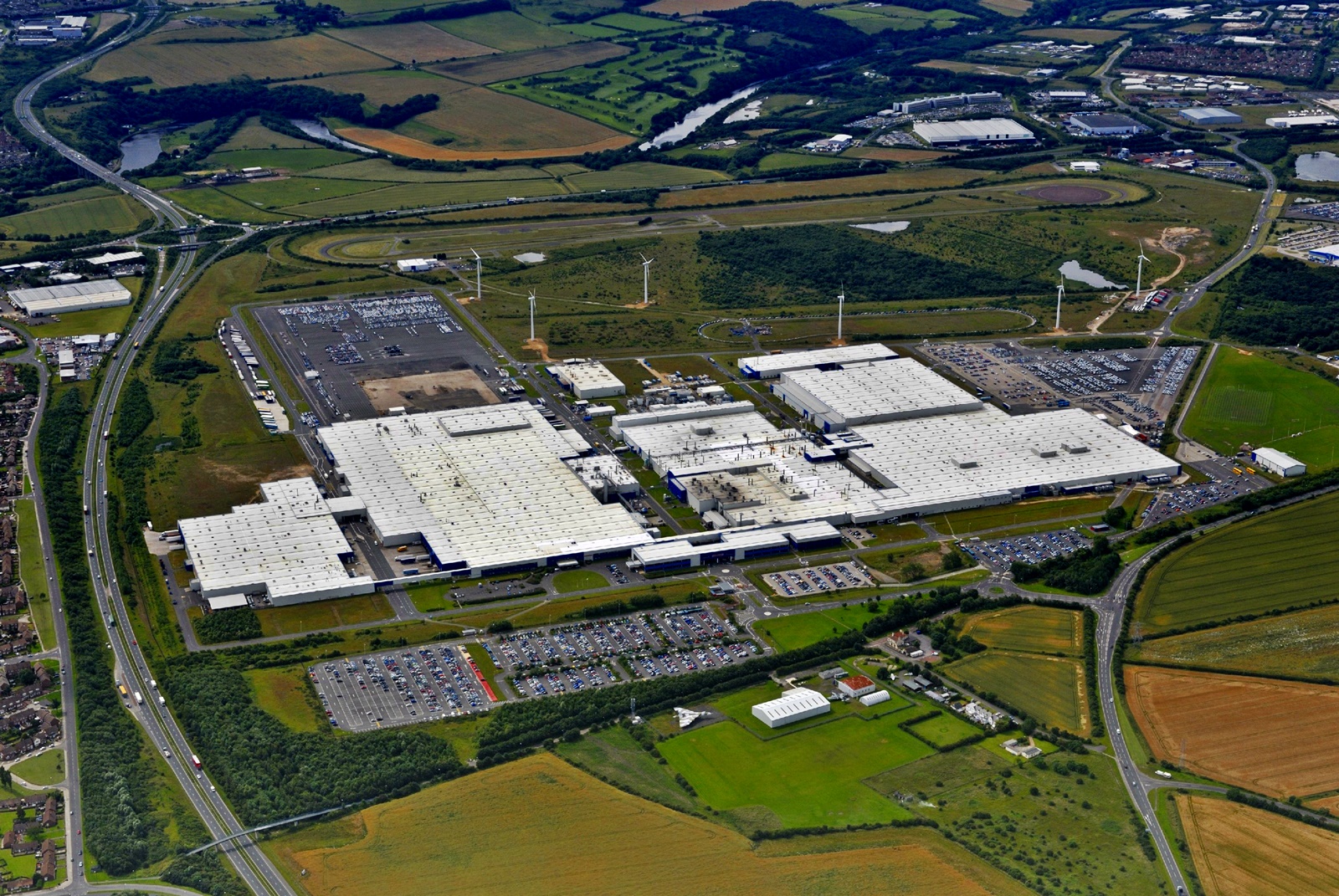

At a former airbase in Sunderland, in the north-eastern corner of England, was chosen for the factory site and operations began from 1986. It has assembled both Nissan and Infiniti models (Q30 and QX30) as well as the LEAF EV since 2012.

Combining past, present and future

Celebrating 35 years of production at the Sunderland plant, Nissan commissioned a very special project which would combine a major past product with the technology of today and tomorrow. Called the ‘Newbird, it is a conversion of the Bluebird model – the first car off the factory’s production line in 1986 – which has its combustion engine replaced by the fully electric drivetrain of a LEAF.

The project was managed by Kinghorn Electric Vehicles, a family-run company based in Durham, just 24 kms from the Nissan factory. Kinghorn EV specialises in the conversion of classic cars to full electric using second-life Nissan LEAF motors, inverters & batteries so they are very familiar with the powertrain.

“Electric vehicles are not just the future, they’re the now! Converting older vehicles to electric gives you everyday use of these iconic vintage models, but they’re just as enjoyable to drive. They’re more reliable and, importantly, don’t produce harmful emissions when driving. With this project, we think we’ve created a car that captures the soul of the Nissan Bluebird, with the heart of a Nissan LEAF, said George Kinghorn, owner of the company.

Change of heart

The Bluebird was extensively modified to integrate the LEAF’s electric drivetrain. The original petrol combustion engine and gearbox were removed and a LEAF motor, inverter and 40 kWh battery pack installed, with the battery modules split between the engine bay and boot for optimised weight distribution.

Updates and modifications were made to the power steering, braking and heating systems to enable them to be electrically powered. A custom suspension was also installed to support the additional weight from the battery packs. To match the car’s electric updates, the original Nissan bonnet badge received a LED backlight (for when the vehicle is static).

For the exterior of the 5-door hatchback car, Nissan Design Europe created a new graphic motif inspired by design cues of 1980s consumer technology, combined with a 21st century aesthetic.

The car is recharged through the original fuel flap on the left side which provides access to the charging port. The battery can be recharged at up to 6.6 kW and the original driver instrument panel has been connected to the EV system to enable the fuel gauge to show the charge level in the battery pack.

The car’s range from a single charge is estimated to be up to 210 kms and should be able to go from 0 to 100 km/h in under 15 seconds. Given the high torque from start that is characteristic of an electric motor, the performance should be zippier than the original. However, the Newbird is not homologated so it cannot be used on public roads.

Production time halved

In 1986, it took over 22 hours for the first Bluebird to be completed. Today, modern manufacturing processes and technologies have halved that time to 10 hours. To date, after 35 years, the number of vehicles produced by the factory has exceeded 10.5 million. Although some scenarios which suggested manpower would drop with more automation, the number of staff employed at the Nissan factory has grown from 430 in 1986 to 6,000 today.

Incidentally, for those who recall the Bluebird being sold in Malaysia, the one in the UK was different. In fact, in the 1980s, Nissan had two Bluebirds produced in different parts of the world and one had front-wheel drive, while the other had rear-wheel drive. So when discussing the model with Nissan executives, one had to first clarify which market was being referred to. The one sold in Malaysia in 1986 was the older one with rear-wheel drive whereas the one built in the UK had switched to the newer front-wheel drive model and was produced in sedan, hatchback and stationwagon bodystyles.

The last Bluebird sold in Malaysia by Edaran Tan Chong Motor was the Bluebird Altima in the 1990s. Nissan officially ended the Bluebird line in 2001 although it did continue with a smaller model called the Sylphy that also carried the Bluebird name.

To know more about current Nissan models available in Malaysia, visit www.nissan.com.my.