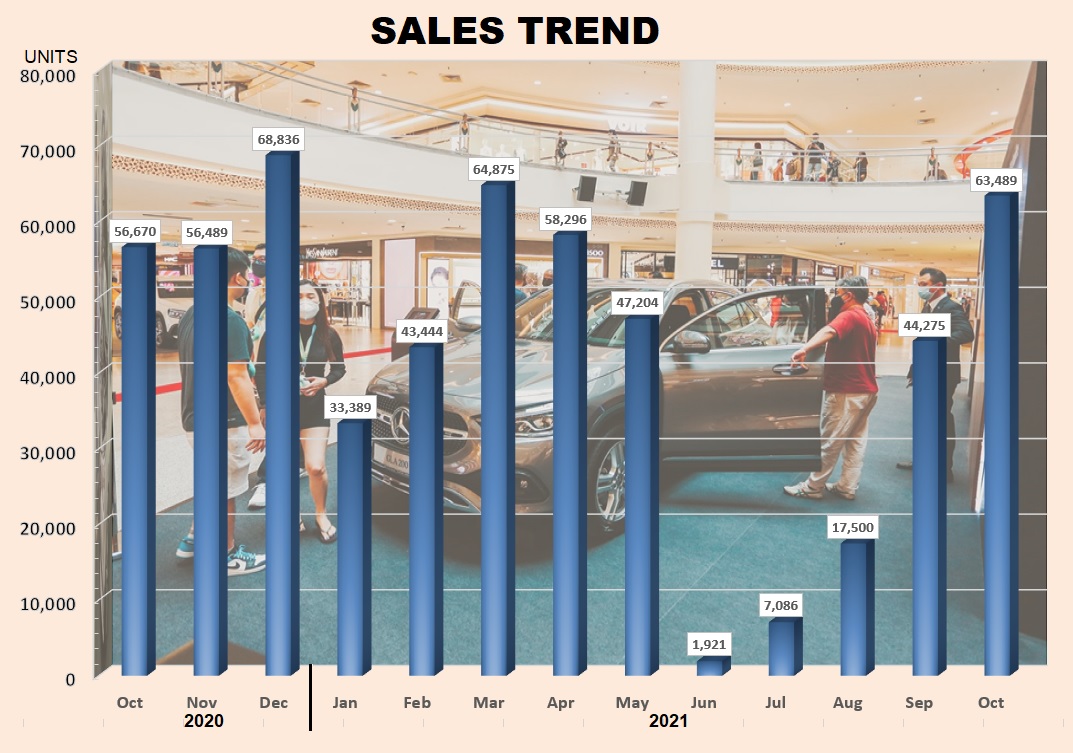

With more days in September and continued progress towards normalising activities in the business sector, new vehicle sales continued to rise. Although 4.8% lower than October 2020, the Total Industry Volume (TIV) of new vehicles registered in the month was 43% higher than September.

It’s uncertain how much of the increase was from new orders as the more popular models from the two leading Malaysia carmakers – Perodua and Proton – have a backlog. Production has been interrupted due to the global microchip shortage which worsens the situation of delayed deliveries which was already evident before the long period of lockdown.

Cumulatively, after 10 months, the TIV has not reached the same level as the 10-month period in 2020 and the 2021 TIV is 382,379 units or 5% lower than the same period in 2020.

The plants have been working flat out to raise output but there is also a dependence on their suppliers, some of whom have their own production issues and disruptions. For this reason, Perodua has ensured that the ‘ecosystem’ remains as intact as possible by helping its suppliers in various ways so that they do not have to shut down.

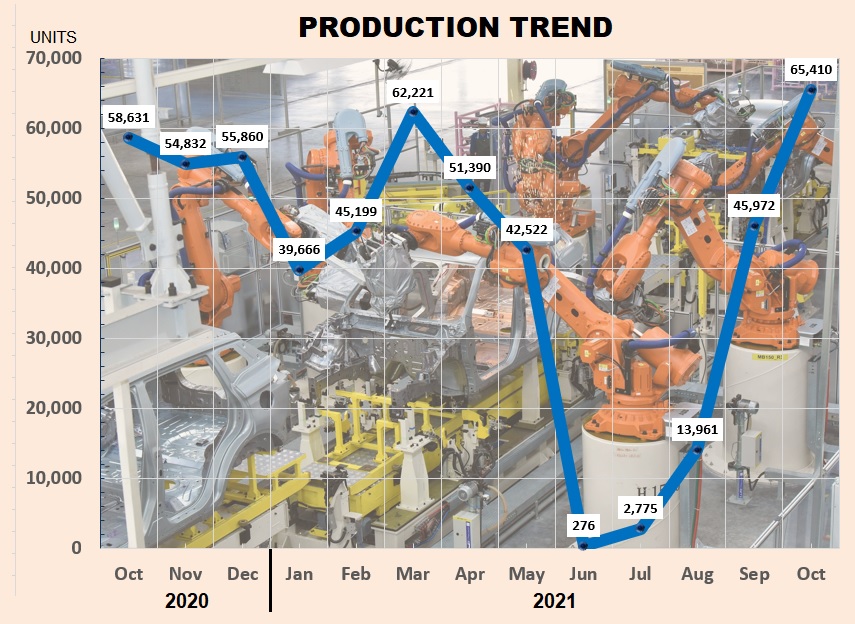

Compared to the same month in 2020, total output in October 2021 was 12% higher with 61,248 passenger vehicles (excluding pick-up trucks) and 4,162 commercial vehicles assembled.

From January to October 2021, the total number of vehicles produced was 369,406 units, about 5,000 units less than the same period in 2020.

The Malaysian Automotive Association (MAA) expects that the TIV has reached a plateau and November numbers will be similar. There may, however, be disruption to supply of imported vehicles as the plants in other countries may be hampered by the microchip shortage. Generally, companies like Perodua expect to be able to maintain production levels until the end of the year as they have a commitment from their suppliers but are undertain of the situation in 2022.