As reported earlier, Porsche will be setting up assembly operations in Malaysia, the first time the sportscar maker has produced its cars outside Germany. The company has confirmed that small-scale local assembly operation in Malaysia will join the company’s two other production sites – the original one at Zuffenhausen and the 19-year old one in Leipzig.

It is believed that the plan to assemble in Malaysia has been under consideration for at least 5 years though it was only early this year that it became known outside the company. There is interest in the Southeast Asian region which is unified under the ASEAN Free Trade Area (AFTA) and member nations have agreed to allow intra-ASEAN exchange of goods and service without import duties. The agreement was signed in the early 1990s and was implemented in the early 2000s.

Carmakers have welcomed the AFTA agreement which allows them to set up a large factory with big volumes in one country to make vehicles for the region. This allows good economies of scale compared to the situation before where each country had low-volume assembly plants to cater only for the domestic market. The regional approach lowers production costs which benefits consumers who get lower prices or better features with the money saved.

Porsche would have likewise seen a similar opportunity, especially since Volkswagen began assembly in Malaysia. However, the initial plan is to assemble in Malaysia from 2022 for the local market only but it’s almost certain that there will be exports later on. This will enable pricing of some models to be more attractive and competitive as they will not be subject to the high import duties that the countries impose for vehicles originating from outside ASEAN.

Sime Darby to be local partner

Not surprisingly, Porsche will have Sime Darby Berhad as its partner in local assembly. Sime Darby Auto Performance, a subsidiary of Sime Darby, also handles the Porsche brand in Malaysia and another subsidiary, Inokom, has an assembly plant in Kedah. Some of the brands assembled at the plant, which began operations in the 1990s, are BMW, MINI, Mazda and Hyundai. BMW engine assembly is also carried out by a subsidiary adjacent to the plant.

First Porsche production facility outside Germany

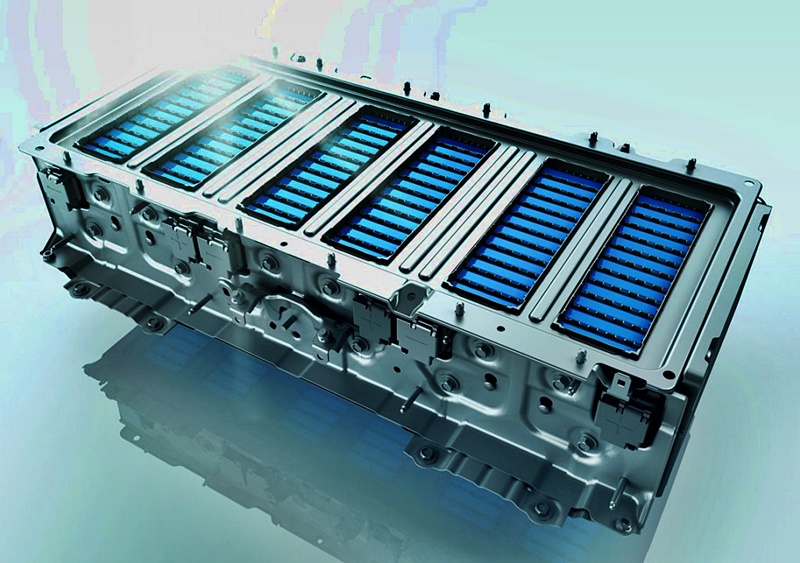

The local assembly operation will not only be something special for Malaysia but also for Porsche as it has never before had to have a CKD (completely knocked-down) process which is required for assembly overseas. It is not just a matter of picking a model and putting it into a box in disassembled form for assembly in another country. The model has also to be engineered for local assembly, taking into account the level of automation at the facility and capabilities of the workforce.

It is possible that the ‘SKD’ (semi knocked down) approach will be taken initially although this approach was stopped by the government in mid-2019. With SKD, bodyshells can be imported already welded together and in some cases, even painted. One thing that will prevent Porsche from exporting from Malaysia initially will be the requirement of 40% ASEAN content in each vehicle in order to qualify for the duty-free privilege. This usually takes while as suppliers have to be found or if they are new, then they will need time to also establish their operations.

Willing to learn and adapt

“We’re fortunate that, due to careful planning, our existing factories are more than up to the task of meeting current and future global demand for our cars,” said Albrecht Reimold, Member of the Executive Board for Production and Logistics at Porsche. “However, the new assembly site in Malaysia meets specific market needs and, although a standalone project and modest in size and capacity, it signals our willingness to learn and adapt to specific local market conditions.”

“Malaysia and the whole ASEAN is a region of great potential, and we look forward to the first locally assembled models reaching our Malaysian customers next year,” added Detlev von Platen, Member of the Executive Board for Sales and Marketing at Porsche. “As Porsche is moving into a new era of mobility, Malaysia and the ASEAN region are gaining an increasing importance. This step now is part of a long-standing initiative to keep pace with rapidly evolving customer and market demands.”