The development of Renault’s E-TECH powertrains drew on the company’s experience in Formula 1 and also contributing has been a LEGO model. Yes, those little plastic blocks that can be attached together to form cars which have entertained children for over 70 years. The development story actually began at the end of the last decade. It was a time when Renault was stepping up its electrification program and advancing hybrid technology was an important step towards developing electric vehicles (EVs).

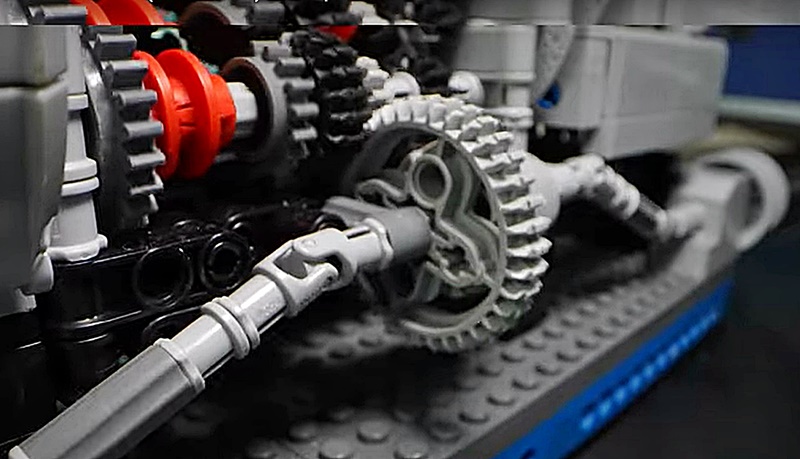

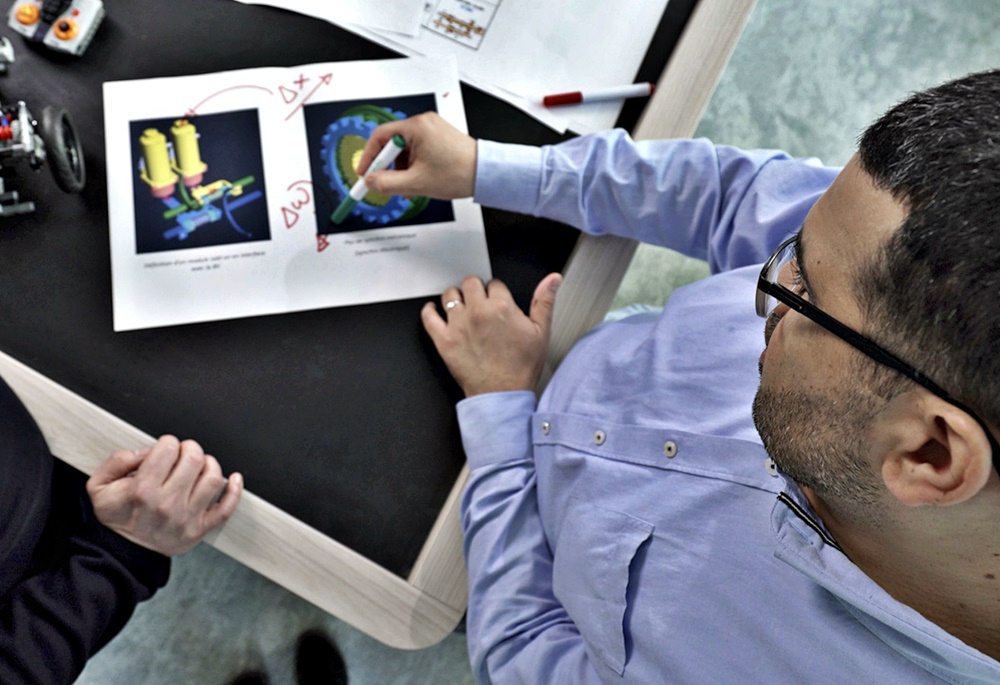

Nicolas Fremau, a member of the hybrid powertrain team, saw that using the LEGO parts – which includes gear wheels, could form a drivetrain. He built a working model from the parts and then demonstrated it to Ahmed Ketfi-Cherif, Renault’s Mechatronics Synthesis Architect and his team. Immediately, the engineers realised that if it could work in the LEGO prototype, it could surely also work as a working powertrain for a car.

Smooth operation a priority

Ahmed, who works as a control specialist, needed to ensure that transitions between driving modes were possible with a simple ‘dog clutch’. Normally used in competition cars, the dog clutch system – which replaces both a sprocket and synchronising ring in a clutchless configuration – is a gearbox boasting superior efficiency due to the reduced number of components.

This particular type of ‘flat’ version works well over time and is more reliable than other types of dog clutch. However, the team needed to find a solution to make the system smoother, as the components are less likely to fit together than in alternative setups such as a ‘roof’ dog clutch. Furthermore, unlike racing car drivers, customers who bought cars from a showroom for daily use also expected quality and smoothness.

“We’re used to using dog clutches in Formula One, for a racing engine. But it was something completely new for a ‘general public’ engine. We had to make this simple object usable by customers,” explained Ketfi-Cherif, who understood that a smooth and refined drive of much higher importance than winning lap times.

Adding a high-voltage starter generator

The team quickly came up with the solution to ensure enhanced smoothness by adding a second electric motor, called a High-voltage Starter Generator (HSG). “Its role is to replace the synchronisers of a traditional gearbox to facilitate the clutch and therefore the gear change. By working in conjunction with the electric motor, it allows very precise regulation of the speed of rotation of the gearbox for smooth gear changes,” he explained.

From this, the original LEGO model concept was updated and tested on the road. They discovered the HSG brought other benefits with immediate torque contribution smoothing acceleration at low speeds, avoiding any break in torque delivery when changing gears.

This also meant the system could operate as a series hybrid for enhanced comfort and flexibility, without the need for an excess of stored energy or a charging socket. According to Ketfi-Cherif, the possibilities for use in the range were multiplied, with both E-TECH hybrid and E-TECH plug-in hybrid powertrains now possible.

At the end of these tests, the E-TECH development teams were reassured that what had worked in the LEGO concept and in simulation also worked ‘extremely well’ in real life. A ‘toy’ had become an engineering reality, allowing up to 80% of urban driving to be done on just electricity, and having the extra boost in power or range with the petrol engine assisting when needed.